Application of small coater in film casting solution

The film coating machine plays an important role in the application of the coating film of the casting solution. Casting solution refers to dissolving polymer materials (such as polyimide, polyetheramide, polypropylene, etc.) in organic solvents to form a polymer solution. Through coating, volatilization, curing and other processes, the liquid polymer material is converted into a solid film material.

Application meaning

The coating application of casting solution needs to control parameters such as coating thickness, quality and uniformity to obtain good film performance. The use of the film coating machine can achieve effective and uniform coating, reducing the error and instability of human operation.

Membrane method

The film making method of casting solution mainly comprises the following steps:

Material preparation: Mix polymer materials and organic solvents in a certain proportion to prepare casting solution.

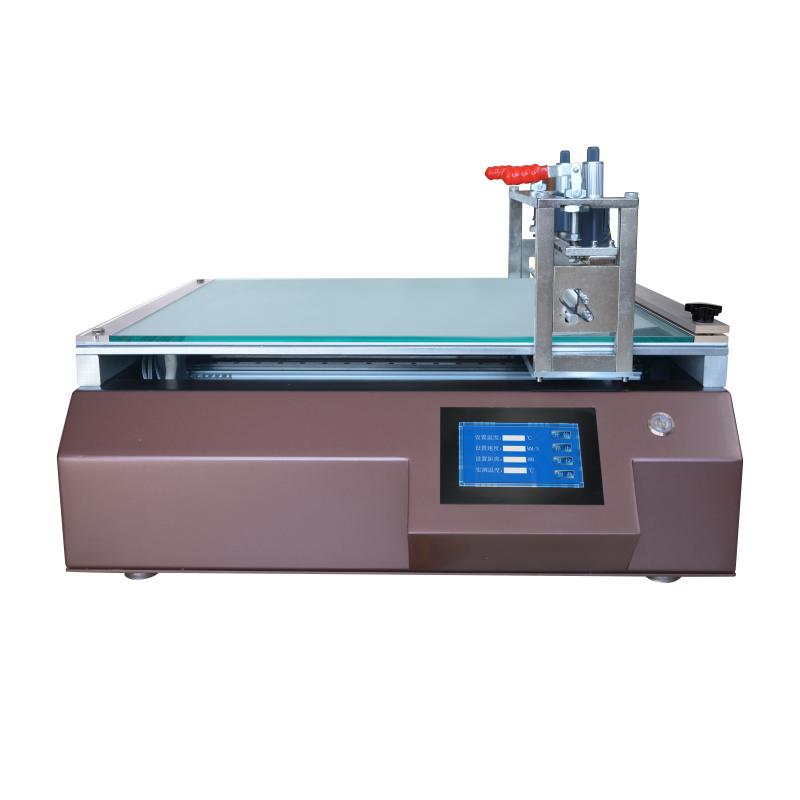

Coating: Pour the casting solution into the coating tank of the coating machine, set the coating thickness and coating speed and other parameters, turn on the coating machine, and evenly coat the coating on the surface of the substrate.

Drying: Send the coated substrate into an oven, and volatilize the organic solvent at a certain temperature to form a solid film-like material.

Solidification: solidify and cross-link the solid film-like material by means of heating and cooling to form a polymer film.

In the coating application of casting solution, the coating machine can realize the control of coating thickness, quality and uniformity, and then obtain good film performance. In addition, the film coating machine can also realize the preparation of film materials with different thickness and quality by adjusting parameters such as coating speed, coating pressure and scraper angle.

In short, the film coating machine plays an important role in the application of the coating film of the casting solution, which can greatly improve the quality and efficiency of the coating film, and provide a reliable means for the preparation of polymer films.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body