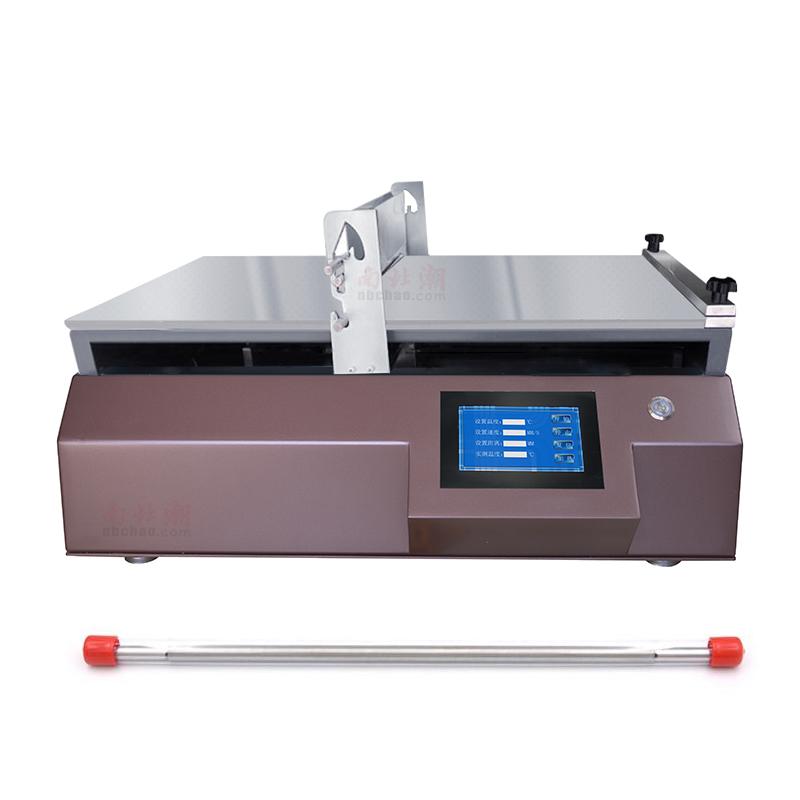

Preparation of liquid crystal film by small film machine

Film coating machine is widely used in the coating application of liquid crystal film. Liquid crystal film is a thin film material commonly used in electronic products, and its surface quality and optical properties have an important impact on product quality. The coating machine can achieve uniform coating of liquid crystal film by controlling parameters such as coating speed, pressure and coating method, thereby improving coating efficiency and quality.

Membrane method

Membrane production methods mainly include wet film production and dry film production. In the preparation process of liquid crystal film, commonly used film-making methods include spin coating method, roll coating method and spray coating method and so on. Among them, the spin coating method is a commonly used dry film-making method, and the conventional steps involved are as follows: dissolve the liquid crystal material in an organic solvent, and then apply it on a rotating substrate, and uniformly coat the liquid film on the substrate by centrifugal force On the surface, it is finally converted into a solid film by drying.

The film coating machine can achieve uniform coating of liquid crystal film, thereby improving coating efficiency and quality. In the application of liquid crystal film, the use of film coating machine can reduce the waste and loss of liquid crystal material, improve production efficiency and save cost. In addition, the film coating machine can also realize different coating methods and coating thicknesses, so as to meet the needs of different application fields.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body