Application of Film Applicator in Preparative Silicon Coating Film

Silicon-coated film refers to coating silicon material on the surface of the substrate to increase the heat resistance, corrosion resistance and wear resistance of the substrate. The film coating machine can be used in the preparation process of silicon coated film.

In the preparation process of the silicon-coated film, methods such as sol-gel method or chemical vapor deposition (CVD) are generally used. Among them, the sol-gel method is to dissolve the silicon material in a solvent to form a sol; then precipitate the silicate in the sol, and prepare a film by drying and sintering. The Film Applicator can be used to apply the sol to the surface of the substrate to form a uniform coating.

Membrane method

Specifically, in the preparation process of the silicon-coated film, the following steps can be adopted:

The silicon material is dissolved in a solvent to form a sol.

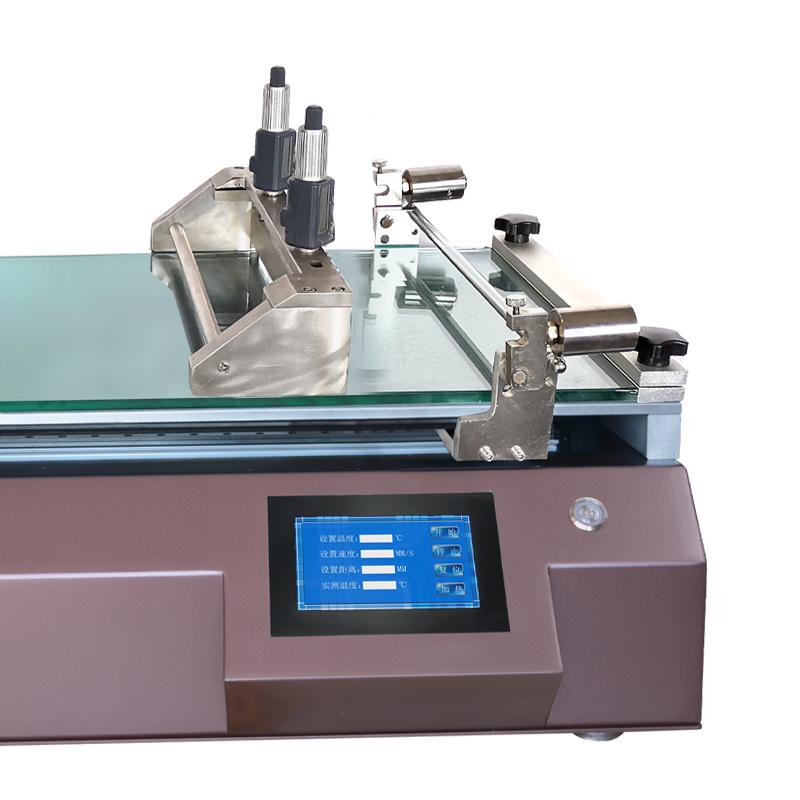

Set the coating parameters of the film coating machine, such as coating speed, coating thickness, etc.

Place the substrate on the workbench of the coating machine, and adjust the distance between the substrate and the coating head to keep it constant.

The sol is applied to the surface of the substrate through the coating head to form a uniform coating.

Send the coated substrate into an oven to dry and solidify to form a silicon-coated film.

NBCHAO reminds you: in the process of preparing the silicon-coated film, the selection and adjustment of the coating head are of great importance to the quality of the coating. In addition, the coating speed and thickness of the film coating machine also need to be adjusted according to the specific process requirements.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body