Coating liquid performance inspection -- paint and Varnish Density Determination

1 Definition, Purpose and Significance

2 Relevant standards

GB/T6750-86 Determination of density of paints and varnishes

ISO 2811-1:1997 Paints and varnishes - Determination of density - Part 1: Pycnometer method

3 Introduction to key points of inspection methods

3.1 Determination of GBIT6750-86 Paint and Varnish Density

3.1.1 Test Principle

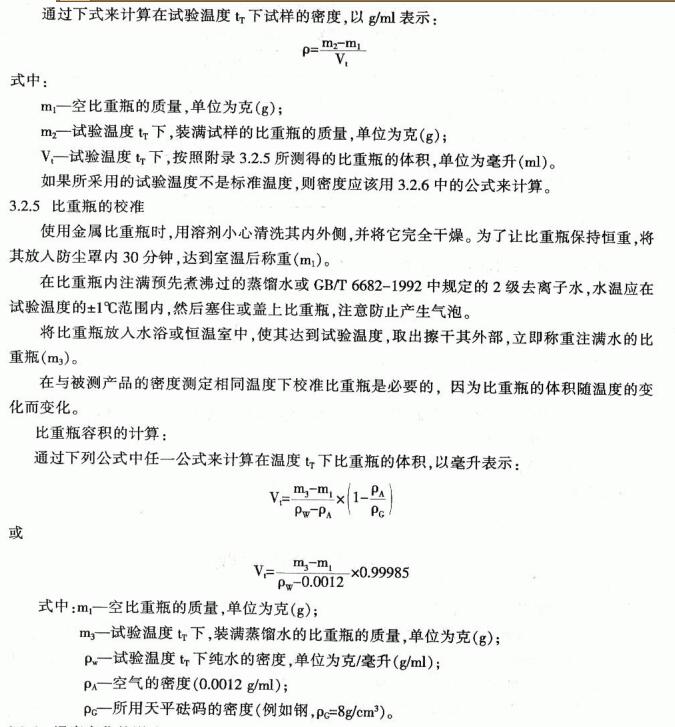

First use the density of plain distilled water to calibrate the volume of the pycnometer, then use the pycnometer to weigh the mass of the filled sample at a certain temperature, and then calculate the density of the sample according to the mass of the sample and the volume of the pycnometer.

3.1.2 Instruments and equipment

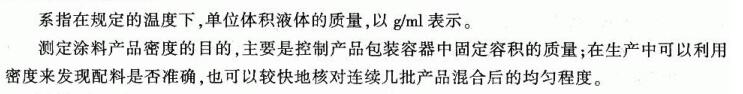

Pycnometer: There are two kinds of pycnometers, one is a glass pycnometer with a capacity of 20-100ml; the other is a metal pycnometer with a capacity of 37ml. As shown in Figure 4 and Figure 5. In the inspection of finished products in the factory, more metal pycnometers are used. Because of its convenient operation and easy cleaning. (Related instrument: specific gravity cup)

3.1.4 Precautions

3.1.4.1 Analytical gloves should be worn during operation. Avoid touching the pycnometer directly with your hands.

3.1.4.2 Before weighing, the pycnometer should be filled quickly to minimize the mass loss of volatile samples.

3.1.4.3 When the sample is injected into the pycnometer, air bubbles should be prevented.

3.1.4.4 Effectively wipe off the overflow around the overflow port to ensure the accuracy of weighing.

3.2 IS02811-1:1997 Determination of Density of Paints and Varnishes Part 1: Pycnometer Method

3.2.1 Test principle

Fill the pycnometer with the product to be tested, and calculate the density of the product to be tested from the mass of the product in the pycnometer and the known volume of the pycnometer.

3.2.2 Instruments

3.2.2.1 Pycnometer

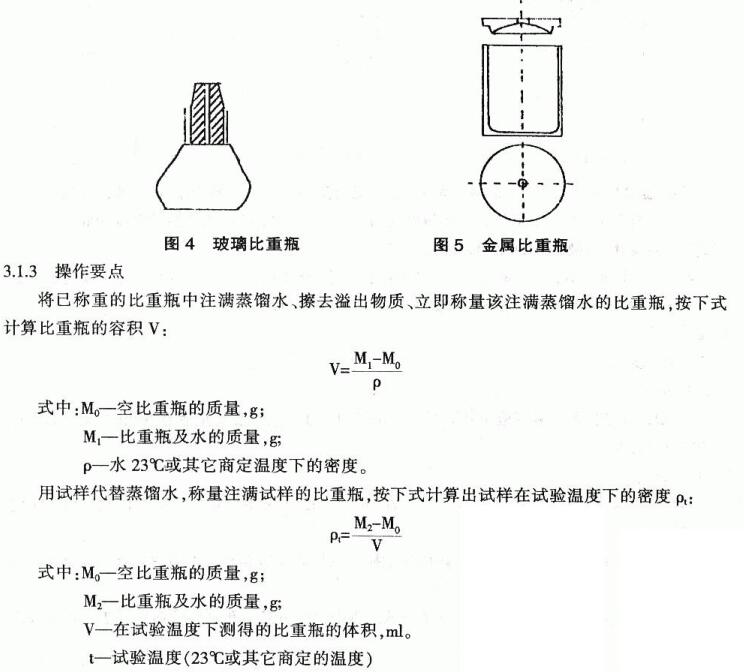

Metal pycnometers, with a capacity of 50ml or 100ml, are cylinders of circular cross-section made of finely machined corrosion-resistant material, with a fitted cap with a hole in the center. The inside of the cover is in the shape of a painting (see Figure 6).

Glass pycnometer, volume 10n, l or 100ml (Guy-Lussack pycnometer or Hubbard pycnometer) (see Figures 7a and 7b).

3.2.2.2 For the analytical balance, the accuracy of the pycnometer below 50ml is 1mg, and the accuracy of the pycnometer between 50ml and 100ml is 10mg.

3.2.2.3 Thermometer, accurate to 0.2°C, with a scale of 0.2°C or less.

3.2.2.4 Constant temperature room or Water Bath. The constant temperature room should be able to adjust and maintain the balance, pycnometer or tested product at the specified or agreed temperature. The Water Bath should be able to maintain the specified or agreed temperature of the pycnometer and the tested sample. (Related instruments: constant temperature and humidity Test Chamber, precision analytical balance)

3.2.2.5 Dust cover

3.2.3 Operation steps

3.2.3.1 General

Perform two assays, each assay should be resampled. After testing about 100 times or when the pycnometer is found to have changed, the pycnometer should be calibrated (according to 3.2.5).

3.2.3.2 Determination

If it is tested in a constant temperature room, put the pycnometer, sample and balance in the dust-proof sheet in the constant temperature room so that they are at the specified or agreed temperature.

If a constant temperature Water Bath is used, put the pycnometer and the sample placed in the dustproof cover into the constant temperature Water Bath to keep them at the specified or agreed temperature, and the temperature can be balanced in about 30 minutes.

Use a thermometer to test the temperature tT of the sample, and check whether the temperature of the thermostatic chamber and Water Bath is maintained within the specified range during the entire test.

Weigh the pycnometer and record its mass m,.

Fill the pycnometer with the product to be tested, and take care to prevent air bubbles in the pycnometer. Stopper or cap the pycnometer, wipe up the spill with absorbent material, and dry the outside of the pycnometer, then wipe gently with a cotton ball.

Record the mass m2 of the pycnometer filled with the product to be tested.

- 1How to measure Coating varnishes Density with Specific Gravity Bottles

- 2Application of Specific Gravity Cup in Coating Density Detection

- 3Specific Gravity bottle Density Error

- 4Paint specific gravity detection method

- 5Frequently Asked Questions about the 2022 Gravity Cup

- 6What is specific gravity? How to measure it?

- 7Main test subjects of powder coatings and their reference standards

- 8What is the specific gravity of ink? How to measure?

- 9Determination of paint density