Pencil Hardness Tester in powder finishing film performance

Powder coating seems to be a solvent-free, all solid powder coating, which is characterized by many colors, environmental friendliness, safety and good coating performance. In recent years, powder coatings have also been widely used in heat-sensitive materials.

In this test, according to the relationship between the substrate treatment and the performance of the coating film, the adhesion of the coating film, impact resistance, pencil hardness, acetone resistance, water vapor resistance, pollution resistance, and dry heat resistance are tested with reference to GB/T17657—

2013 "Test methods for physical and chemical properties of wood-based panels and veneered wood-based panels"; test for hydrochloric acid resistance and alkali resistance refer to GB/T9274-88; test for coating abrasion resistance refer to GB/T4893.8-85.

Test Results and Analysis

Influence of powder amount on coating film quality

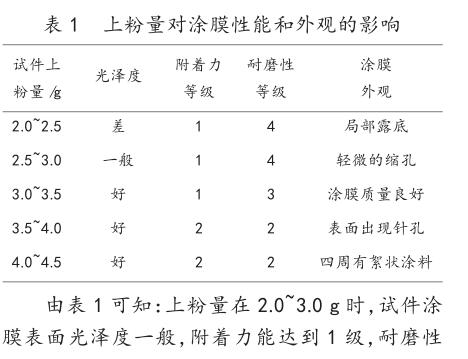

Fifteen OSB samples coated with water-based putty were subjected to powder electrostatic spraying test, and the results are shown in Table 1.

The application of the pencil Hardness Tester in the performance of powder coating film can be seen from Table 1: when the powder amount is 2.0~3.0g, the surface gloss of the test piece coating film is average, the adhesion can reach level 1, and the wear resistance is not good enough to be level 4. Level, the appearance of the coating film has bottom leaks and slight shrinkage cavities ; when the amount of powder applied is 3.5~4.5g, the surface gloss of the test piece is very good, the adhesion drops to level 2 due to the increase in the amount of powder applied, and the wear resistance is improved When it is upgraded to level 2, there are more pinholes in the appearance of the coating film; when the powder amount is 3.0~3.5g, the gloss of the coating film is good, and the adhesion, abrasion resistance and appearance of the coating film are all good (no leaks, pinholes, etc.) . Therefore, considering the above-mentioned adhesion, gloss, wear resistance, appearance quality and cost, the appropriate amount of powder is 3.0~3.5g; through formula 1, the amount of powder per unit area is 144.79~168.92g/m 2 . If the amount of powder applied is too small, the surface gloss will not be enough, the base material will leak out, and the coverage of the coating film will not be high, and the surface layer will have slight shrinkage; if the amount of powder applied is too large, the distance between the outer powder particles and the board will increase. The electrostatic attraction of the plate to the powder becomes smaller and smaller, and at the same time, each negatively charged powder particle begins to repel each other, and the pores between the powder particles further increase, resulting in the powder particles being brought to the surface of the plate by the air. Instead of being attracted by the plate, it is repelled by the negative electric field superimposed by the powder layer, making it difficult to adhere, resulting in a decrease in the level of adhesion, and flocculent paint around the coated sample.

- 1Film hardness testing method: pendulum hardness, pencil hardness, etc

- 2ISO 15184 Pencil method to measure the hardness of paint film

- 3Analysis of hardness measurement by ASTM D3363 pencil method

- 4Pencil Hardness Tester test procedure, application and different Hardness Pencil introduction

- 5Pencil hardness testing of film

- 6Ceramic Coated Pencil Hardness Test

- 7Relevant standards for pencil Hardness Testers

- 8What is a pencil hardness test?

- 9What are the performance requirements of polymer cement for floor coating?