How is Coating covering power measured?

1 Definitions, Purpose and Significance

2 Relevant Standards

GB/]T 1726-79 (89) Paint Hiding Power Determination Method

GB/T9755-2001 "Synthetic tree J refers to emulsion exterior wall coatings" in 5.8, GB/T 9756-2001 "Synthetic resin emulsion interior wall paints" in 5.8 and GBn 9757-2001 "Solvent-based exterior coatings" 5.7 pairs ratio.

3. Introduction to the key points of the test method

3.1 GB/T 1726-79 (89) Paint Hiding Power Determination Method

3.1.1 Test Principle

Using a black self-spaced glass plate, the paint is evenly and quickly applied with a paint brush until the black self-grid is not visible, and the amount of paint used is weighed to obtain the hiding power g/m2 (measured by wet paint film or dry film). (Related Instruments: Concealment Paper)

3.1.2 Materials and instruments

Paint brush: width 25-35 mm

Broken glass plate (JG40-62) 100x100x1.2-2 mm

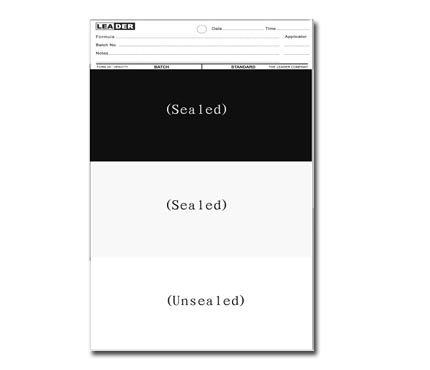

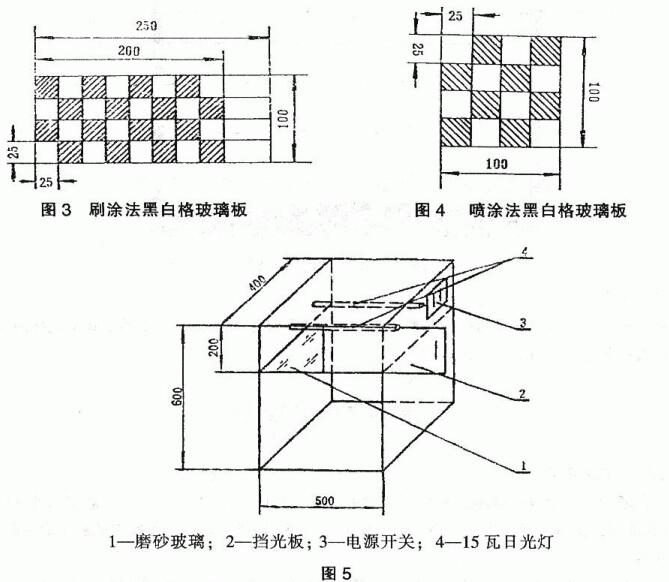

Brushing black and white lattice glass plate: as shown in Figure 3

Spraying black self-grating: as shown in Figure 4

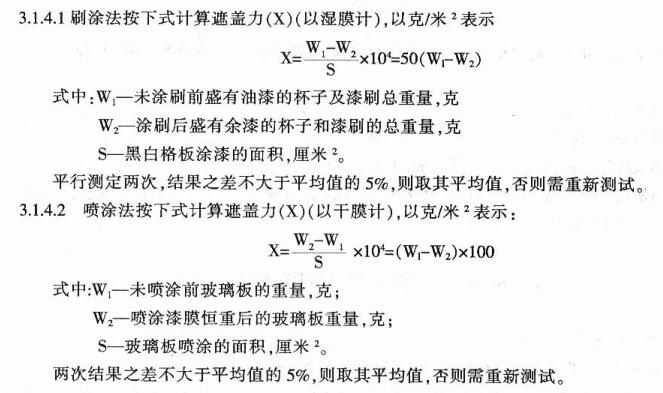

Wooden camera obscura: 600x500x400 mm, as shown in Figure 5

3.1.3 Operational Points

3.1.3.1 Brushing method

The total weight of the paint-filled cup and paint brush is weighed on a balance with an inductance of 0.01 grams, according to the viscosity specified in the product standard. The paint is evenly applied to the glass black self-grid with a paint brush, placed in a camera obscura, 15-20 cm away from the frosted glass sheet, and one end of the black and white grid is inclined to the plane at an angle of 30-45°, and is observed under 1 and 2 fluorescent lamps, ending with the black and white grid that is just invisible. The cup with the remaining paint is then weighed together with the paint brush to find the weight of the paint on the black and white grating.

If the viscosity is too large to be painted, the sample should be adjusted to the viscosity of the brush, but the amount of diluent should be deducted when calculating the hiding power. For example, 100g of original paint, add solvent (10g), use 1.5g of diluted paint after brushing, deduct solvent, the amount of original paint is (1.5gx100/110), and finally calculate.

3.1.3.2 Spraying method

Adjust the sample to the viscosity suitable for spraying, first weigh the weight of the glass plate of the commercial block l00x100mm, spray it thinly in layers with a Spray Gun, put it on the black self-grid after each spraying, and observe it in the dark box, and take the black and white grid as the end point. Then wipe the paint off the back and edges of the glass pane. All kinds of spray paints are baked to constant weight according to the baking temperature specified in the solid content.

3.1.4 Presentation of Results

3.1.4.1 The brushing method calculates the hiding power (X) (in terms of wet film) according to the following formula, expressed in grams per m2

3.1.5.l The endpoint needs to be observed in the camera obscura

For example, when observing under natural scattered light, the light intensity is different at dawn, noon, evening, sunny and rainy days, which affects the judgment of the end point. When observing in the obscura, one fluorescent lamp should be used for light-colored paint, and two fluorescent lamps should be used for dark-colored paint.

3. 1 5.2 When using the brushing method, the brushing should be fast and uniform, reduce the volatilization of solvents, and the special paint should not be painted on the edge of the glass plate or fall elsewhere during the brushing process.

3.2 GB/T 9755-2001 "Synthetic resin emulsion external culture coatings" in 5.8; GB/T9756-2001 "Synthetic resin emulsion interior wall paints" in 5.8 and GB/T9757-2001 "Solvent-based exterior wall paints" 5.7 in the ratio.

3.2.l Test Principle

The specimen is coated on a thin sheet of colorless transparent polyvinegar or on cardstock with a black and white background. , the reflectivity of the coating film on the black and white bottom surface is determined by a reflectance meter, which is on the black and white background; The ratio of the reflectivity on the surface is the contrast ratio.

3.2.2 Materials and Equipment

Wire bar applicator: Specification 1oo gap type paint film preparer: 100

Polyester film: colorless and transparent, with a thickness of 30μrn-50μm

Reflectometer: A photoelectric instrument that gives an indication reading proportional to the reflected luminosity of the tested surface with an accuracy of less than 0.3%.

, its spectral sensitivity is approximately equal to the product of the relative spectral energy distribution of the CIE light source C or D65 and the color coordinates of the Cni standard observer by the function y (in).

3.2.3 Operational Points

Use a wire rod or an inter-colored paint film preparer to evenly coat the tested paint on the polysheng film or black and white card stock, and test it after 24 hours. If the polyester film is used as the substrate to make each coating film, the painted polyester film is attached to the black self-working plate attached to the instrument with a few drops of No. 200 solvent oil (or other solvents), and different positions are selected for reflectance testing. If the coating film is prepared with black and white card stock, it is tested directly on the black self-background coating film. Calculate the average reflectance RB (on chalkboard paper) and Rw (on whiteboard paper) separately.

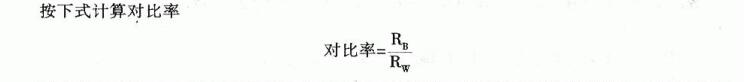

3.2.4 Presentation of results

If the difference between the two measurement results is not greater than 0.02, the average of the quotient measurement results will be taken, otherwise the test will be retested.

3.2.5 Precautions

3.2.5.1 When preparing the coating film, the scraping speed should not be too fast, and the force should be uniform.

3.2.5.2 The polyester film should maintain optical contact with the blackboard and self-board, and there should be no bubbles.

3.2.5.3 The instrument should be warmed up for more than 15 minutes before use, and the probe should be placed on the zero adjustment board during repeated zeroing, calibration, and continuous testing. to prevent photofatigue of selenium photocells.

- 1Paint transparency detection method

- 2Summary of determination methods for hiding power of coatings

- 3Pigment hiding power

- 4Determination of Coating hiding power

- 5GB/T 23981.2-2023: Paints and varnishes - Determination of hiding power - Part 2: Checkerboard method - Interpretation

- 6Concept, influencing factors and determination method of Coating hiding power

- 7Mayer Rods: The right-hand man for hiding power tests

- 8Coating performance testing: ensuring the efficiency and mass of the painting process

- 9Coating hiding power measurement

-

-

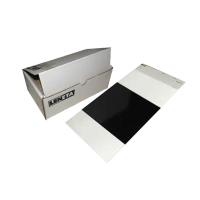

Leneta WB sealed film, pure white$ 298.00

-

-

Leneta Form 2C Opacity Chart$ 306.00

-

-