How is film thickness measured?

1. Purpose and significance

2 Relevant standards

GB/T13452.2-92 Paints and varnishes - Determination of film thickness

3 Introduction to key points of inspection methods

3.l GB/T13452.2-92 Paints and varnishes - Determination of film thickness

This standard specifies methods for measuring paint film thickness under certain conditions. There are 6 methods in total. Method 1 to Method 5 are methods for measuring dry film thickness, and Method 6 is a method for measuring wet film thickness.

3.1.1 Method 1

This method is used for air-dried coatings with hard and slow-drying paint films. These paints need to dry for several days to form a paint film hard enough to allow the use of instruments to measure thickness. It is mainly used for test panels in the early stage of curing of air-drying paint.

3.1.l.1 Test principle

Dry film thickness is measured by the corresponding relationship between dry film mass and dry film thickness.

3.l.12 Instruments and equipment

Paint Film Applicator (wire Bar Coater)

Precision Analytical Balance

indicator

Drying box (oven)

3.1.1.3 Operation points

① Draw the relationship between paint film quality and paint film thickness

Select paint Film Applicators of different specifications to coat the paint on the polyester film of similar quality, place the painted polyester film and the unpainted polyester film horizontally in the dry box at the same time, and dry them at a certain temperature Baking, remove the painted and unpainted polyester film of the same area with the center of the modular polyester film, weigh it, and calculate the mass of the paint film per square meter; use the indicator to measure the painted and unpainted polyester film. The thickness of the film was calculated, and the thickness of each painted polyester film was calculated, and the relationship between the quality of the paint film and the thickness of the paint film was drawn.

② Measured on the test plate

Apply the sample on the weighed sample in an appropriate way, dry it in an appropriate way, weigh it, calculate the mass of the dry film per square meter, and calculate the corresponding film thickness according to the above relationship diagram.

3.1.1.4 Result presentation

The value given is an average film thickness in micrometers (µm).

3.1.2 Method 2: micrometer method

This method is suitable for flat surfaces of small-sized metal plates or similar materials used in laboratories, and can also be used for the measurement of round rod coatings.

3.1.2.1 Test principle

The distance between the two measuring faces of the lever micrometer is determined to obtain the corresponding paint film thickness.

3.1.2.2 Instruments and equipment

Common lever micrometer

3.1.2.3 Operation points

Firstly, adjust the zero point of the instrument and measure the thickness of the painted bottom plate. After the paint is dry, measure the total thickness at the same part. The difference between the two is the paint film thickness.

3.1.2.4 Result presentation

Measured in microns (µm).

3.1.3 Method 3: Indicator method

This method is used to measure flat painted test panels.

3.1.3.1 Test principle

The thickness of the paint film can be obtained by measuring the height difference between the paint film and the substrate with the stylus of the instrument.

3.1.3.2 Instruments and equipment

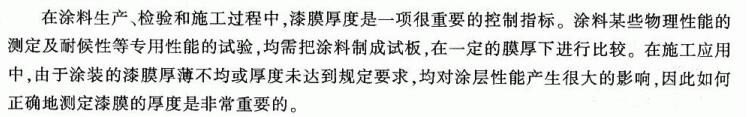

Indicating table, the common disc-shaped dry Film Thickness Gauge such as E, ichsen233 type (Germany Eriohen company), as shown in Figure 6:

3.1.3.3 Operation points

First scrape a small part of the paint film to expose the substrate, then press the instrument to make the stylus measure the height difference, and the paint film thickness will be displayed on the dial.

3.1.3.4 Result presentation

Measured in microns (-).

3.1.4 Method 4: Microscopy

This method also stipulates two methods, namely A method and B method, which are used to measure the dry film thickness on different substrates respectively.

3.1.4.1 Method A

It is a general method for measuring the dry film thickness of a section cut from a test panel or painted object. It is especially useful when measuring changes in paint film thickness due to unevenness of the substrate.

①Test principle

After the test block is processed, it is placed under the microscope, and the scale on the eyepiece is used to directly measure and read the paint film thickness.

②Instrument settings

microscope

③Operation points

Inject the cut test block into the resin, expose the cross-section after treatment, place it under a microscope, and use the scale on the eyepiece to measure the thickness of the paint film.

④Result display

Measured in Huimi.

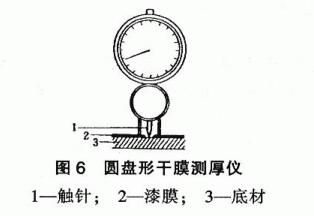

3.1.4.2 Method B

This method does not involve the cutting of the test block, directly measured under the microscope.

①Test principle

Cut a V-shaped notch from the paint film to the substrate, measure the width of a', b, and get the paint film thickness a, b in proportion. As shown in Figure 7:

②Instrument settings

Common instruments are multi-purpose dry film Testers.

③Operation points

Select an angled knife to cut the coating to the substrate, and the film thickness can be read directly from a microscope with a ruler.

④Result display

Measured in microns.

3.1.5 Method 5

3.l.5.l Non-destructive instrumental measurement methods

This method can be used to measure the film thickness on magnetic metal substrates and non-magnetic metal substrates.

①Test principle

The operating principles of various instruments are different, mainly as follows:

a. The principle of magnetic flux: it is measured according to the change of the magnetic flux with the thickness of the non-magnetic layer of the paint film between the magnet and the substrate.

b. The principle of magnetic attraction detachment: the thickness of the paint film is measured by the force required to overcome the magnetic attraction between the permanent magnet and the magnetic substrate.

c. Eddy current principle: use the alternating magnetic field generated by the probe to form an eddy current in the metal substrate, and measure it according to the size of the induced eddy current

Paint film thickness.

②Instrument and equipment

Magnetic and non-magnetic Thickness Gauges, the common ones are:

Elcometer 345型(测试范围 0~1250µm) (英国埃高仪器公司) ,主要用于磁性底材(运用磁通量原理)。

Mikrotest 6G型(测试范围 0-100µm)(德国 Elektro-Physik公司即 liPK公司) ,主要用于磁性底材(运用磁吸力脱离原理)。

Qua「'b【 5500型(测试范围 0-2000µm) (德国科隆仪器公司) ,仪器为双测头结构,磁性及非磁性底材上均可使用(运用温流原理) 。

③操作要点

Elcometer 345型:仪器经置零和调校后,将测头置于被测漆膜上即可测定。

Mik-esl 6G型:将仪器刻度盘量程推至最大,按动按钮,仪器即自动测定。

QuaNix 5500型:仪器无需校准,将测头直接置于被试漆膜上即可测定。

④结果表示

以微米(µm)计。

3.1.5.2 β射线反向散射法

此法主要用于移动中漆膜,如卷材涂层的连续测定。

①测试原理

According to反散射强度取决于底材和涂层的原子序数之间差异的原理,测量単位面积涂层的质量, 即可得到测量面积内的平均厚度 。

②仪器设备

常见的有 Fisherscope MMS(Betasoope型)β反散射仪(测试范围 0~200µm)(德国 HliLMUT_F「SHER公司)

③操作要点

先用有均匀涂层厚度的标准来校正仪器,除连裝测量或大面积测量外,測量时试验样被应稳固地对着测量孔 。

④结果表示

以微米(µm)计。

3.1.6 方法6:湿膜厚度的测量

此法中规定了两种测定方法:轮规和流规前者适用于实验室和施工现场,后者只适用于施工现场,作組略测定 。

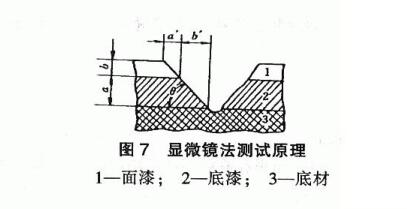

3.1.6.1 轮规

①测试原理

由三个轮同轴组成一个整体,直径为50mn,厚度11mm,中间轴与外側两个轮偏心,具有高度差,轮外側有刻度,以指示不同间隙的读数,如图8所示:

②仪器设备

常见的有 QluL型轮规(测试范围 0-150µm)(天津市伟达试验机厂)

③操作要点

把轮规垂直压在被试湿膜表面,从最大读数开始滚动到零点,湿膜首先与中间偏心轮接触的位置即为湿磁厚度 。

④结果表示

Measured in microns (µm>).

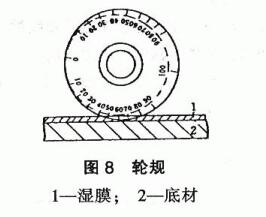

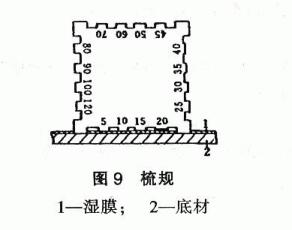

3.1.6.2 Flow gauge

①Test principle

The instrument is composed of flow teeth, the outer teeth at both ends are on the same horizontal plane, and the middle teeth have different clearances from the horizontal plane in order, indicating different readings, as shown in Figure 9:

②Instrument and equipment

The common one is sHG-100 type (test range 0~100µm) (Shanghai Modern Environmental Engineering Technology Research Institute)

SHG-200 type (test range 0-200µm)

SHG-700 type (test range 0-700µm)

SHG_750 type (test range 50-750µm)

③Operation points

Press the comb gauge vertically on the surface of the wet film to be tested, and part of the teeth are wetted. The thickness of the wet film is the reading between the last tooth to be wetted and the next tooth to be wetted.

④Result display

Measured in microns (µm).

- 1Principle, Characteristics and Application of Wet Film Comb

- 2Determination method of dry and wet paint film thickness

- 3Coated steel coatings - Determination of dry-film thickness

- 4Dry-film thickness measurement: an important step before Coating mass evaluation

- 5How to detect the thickness of steel structure paint?

- 6How to convert Dry-Film and wet film thickness of concrete structure paintings?

- 7Measuring method of ISO 2808 film thickness

- 8Coating Thickness Gauge measurement circuit board film thickness scheme

- 9Epoxy asphalt film thickness measurement solution