Cataphoretic coatings film performance

The performance of the coating film is the basis for the selection of electrophoretic coatings. The performance of the coating film is affected by many factors, such as the nature of the coating itself, the relevant components of the electrophoretic fluid, and the processing technology (such as voltage, solution temperature, electrophoresis time, curing temperature, etc.). Coatings produced by different manufacturers have different coating properties. From the perspective of use, people are generally concerned about the following main properties: appearance, hardness, adhesion, corrosion resistance, weather resistance, etc. Due to the different test methods and conditions used by each manufacturer, the results are not completely consistent. as listed

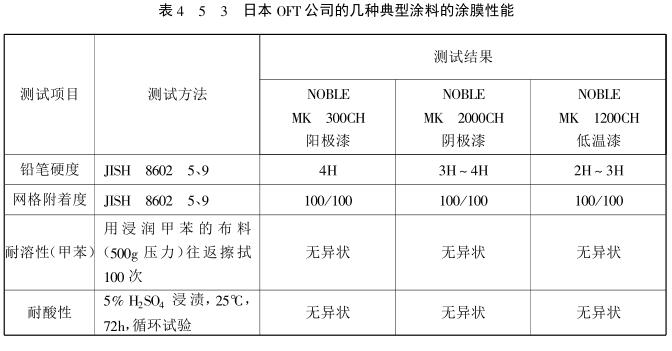

Japan's OFT company's typical coating performance, including pencil hardness adopts JISH 8602, and the hardness is 4H, 3H-4H, 2H-3H.

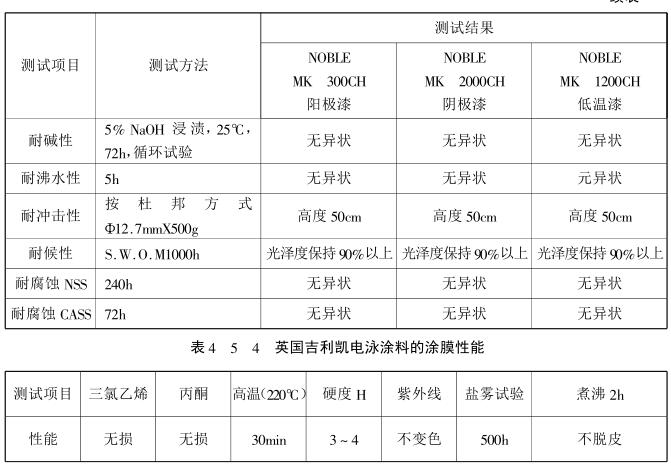

British Geely Kai electrophoretic coating, its weather resistance requires MK 300CH, MK 2000CH, MK1200CK to keep the gloss above 90%.

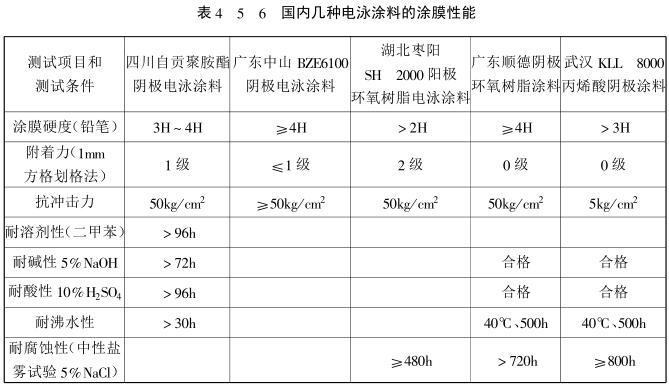

In CHINA, taking Shunde anodic epoxy resin coating as an example, the hardness of the coating film (pencil Hardness Tester) should be > 4H, the adhesion (1mm square grid method) should be 0, and the impact resistance should be 50kg/c㎡. Corrosivity > 720 hours.

- 1Determination of pH value of electrophoretic paint - PH meter is easy to do

- 2Discussion on water-based paints performance testing

- 3What causes poor paint film performance?

- 4Film performance inspection - Preparation of test plate

- 5Maintenance and management of electro-coating ultrafilter

- 6Cataphoretic coatings - Determination of main performance

- 7Management summary of electro-coating

- 8Summary of post-treatment of electro-coating

- 9What are the factors that affect the electro-coating process?