Methods and characteristics of electro-coating

First, the method of electrophoretic coating

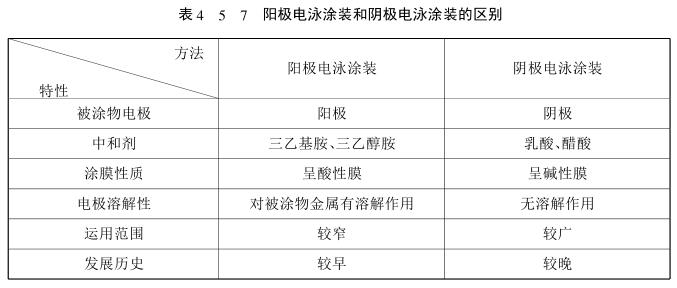

Due to the different properties of electrophoretic coating itself, it is divided into two types: anodic electrophoretic coating and cathodic electrophoretic coating.

The functional groups of anodic electrophoretic coatings contain hydroxyl groups. After being neutralized with organic amines or alkalis, they are water-soluble or water-dispersible. They dissociate into negatively charged particles in water and are deposited with the object to be coated as the anode during electrophoretic coating. It is called anodic electrophoretic coating.

There is a big difference between anodic electrophoretic coating and cathodic electrophoretic coating (see table). The type of coating used, the performance of the solution, the electrophoresis process and the coating properties are all significantly different.

Second, the characteristics of electrophoretic coating

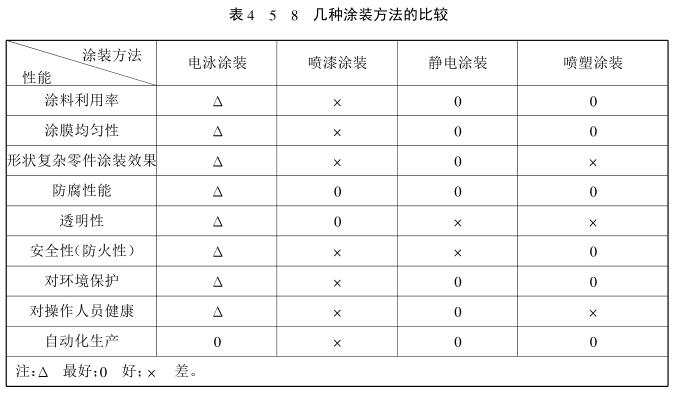

Compared with electrostatic spraying and powder spraying, electrophoretic coating has very significant features (see table):

(1) The utilization rate of paint is very high, generally above 95%. If the ultrafiltration device is used for recycling, the utilization rate

Can be as high as 98% or more;

(2) The thickness of the coating film is uniform (coating film rod), and the binding force is strong;

(3) The hardness of the coating film is high, generally up to 3H-4H (pencil Hardness Tester);

(4) The swimming penetration is good, and it can be evenly coated on the inner cavity and welding seam of the parts;

(5) The anti-corrosion performance is very good. If the film thickness (film thickness meter) exceeds 25μm, the neutral salt spray test can reach more than 500h, and no obvious corrosion will occur;

(6) The electrophoretic coating film has a good appearance, is not easy to sag, and does not cause paint hanging.

(7) Due to the use of water-soluble paint, it does not burn, and the safety is greatly improved, which is harmful to the health of operators

Small;

(8) Reduced environmental pollution, with little air and water pollution;

(9) It can realize automatic production and improve production efficiency;

(10) It can be combined with electroplating to obtain various colored coating films on the metal surface, which has a strong metallic feel, and the anti-corrosion and use functions become more perfect, which promotes the development of surface treatment technology.

- 1Under what conditions can electrostatic spraying equipment be selected?

- 2Characteristics and process of electro-coating

- 3Overview of roller painting

- 4Advantages of coating powder and its production process

- 5On-site management of electro-coating

- 6Electro-coating limitations and benefits

帅长红 - 《电泳涂装新工艺新技术》

- 7Thickening (precipitation) mechanism of electro-coating film

帅长红 - 《电泳涂装新工艺新技术》

- 8Electro-coating and its principle

帅长红 - 《汽车车身涂装新工艺新技术》

- 9Floor painting method of painting