Electrochemistry coloring process

1. Process flow

Workpiece phosphating→cleaning→soaking in distilled water→color electrophoretic coating→recycling→cleaning→drying.

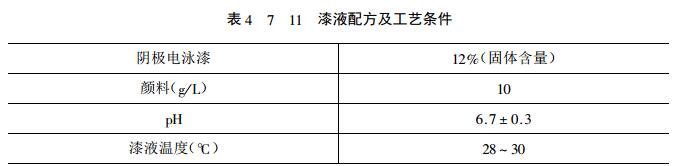

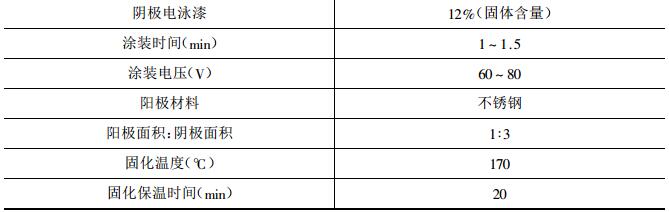

2. Paint formula and process conditions

The paint formula and process conditions are shown in the table

The solid content of cathodic electrophoretic paint is 36%, and it needs to be diluted when used, and the pigment is added after dilution. The preparation steps are:

(1) Take the electrophoretic varnish and put it into the container according to the calculation;

(2) Add distilled water under continuous stirring, and continue stirring for about +2;

(3) After stirring evenly, add the required pigment and continue stirring -2;

(4) Test after heating to the specified range.

It should be noted that the heating of the electrophoretic paint solution requires a water-proof heating or low-temperature heating device with a constant temperature controller.

3. Influence of process formula and operating conditions

1) The solid content of the paint liquid If the solid content is too high, the rough paint film will cause the orange cloth to hang; if the solid content is too low, the paint film too thin to cause defects such as pinholes. The solid content is not less than 10%. During the electrophoresis process, the solid resin particles in the paint liquid are continuously deposited and partly taken away by the workpiece at the same time, so the solid content will continue to decrease and need to be replenished continuously.

2) During pigment electrophoresis, the pigment and resin are precipitated together, and part of it is taken away by the workpiece at the same time, and its concentration is continuously reduced, so it must be replenished frequently. If the pigment concentration is too low, the color depth is not enough, and edge shrinkage will occur at the same time. Concentration too

Large, the covering ability of the film layer is high (recommended equipment: covering power paper), but the color is not bright.

3) The voltage is generally 60-80V. If it is too high, the paint film will be too thick, and it will become rough and affect the transparency. Too low, the paint film is thin, the color is light and the film layer is not full.

3) Temperature The temperature of the paint solution is generally within the range of 28-30°C. As the temperature increases, the viscosity of the paint liquid (recommended instrument: viscometer) decreases and the deposition rate increases. However, if the temperature is too high, the paint film is prone to orange peel phenomenon; if the temperature is too low, the electrophoresis speed will slow down and the paint film will be uneven.

4) Curing temperature and time The curing temperature is between 170-180°C. Below this temperature, the paint film is difficult to cure and also affects the hardness of the paint film (recommended instrument: Hardness Tester); if the temperature is too high, the paint film becomes brittle and yellow. The curing time is controlled at 20-30 minutes. If the time is too short, the film layer will not be completely cured, and it is unnecessary if it is too long.

Application examples

1. Application of chemical coloring process

The surface treatment of automobile clutch parts, get a color film, and the appearance is satisfactory.

2. Application of electrochemical coloring process

Put the phosphating clutch parts into the above cathodic electrophoretic paint solution, apply 80V voltage, and paint for 1-1.5min.

And cured at 170°C to obtain phosphating layers of various colors. The film layer is thicker, and the anti-rust performance is also good

- 1MB35 halogen Moisture Analyzer: a tool for accurately measuring volatile matter

- 2What subjects are generally tested for architectural paint color paste?

- 3Ball Mill vs Basket Mill - What is the application? How are they different?

- 4What is paint solids content? How to test?

- 5What are the technical requirements for latex paint for synthetic resin emulsions?

- 6Electrochemistry of epoxy resin Coatings

- 7Resin percent solids

- 8Determination method of Non-volatile content

- 9How to measure the Non-volatile of Coatings?