FAQ and solutions in exterior wall painting

1. Hanging

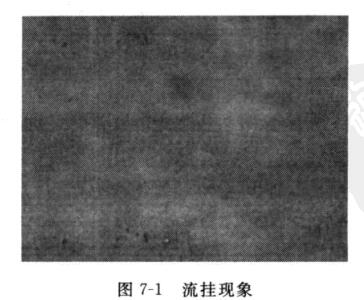

After the coating is applied, the coating film is partly sagging or flowing. See Table 7-2 for the cause, prevention and repair of the sag. See Figure 7-1 for the sagging phenomenon. (Related instruments: flow meter)

2. Rain marks

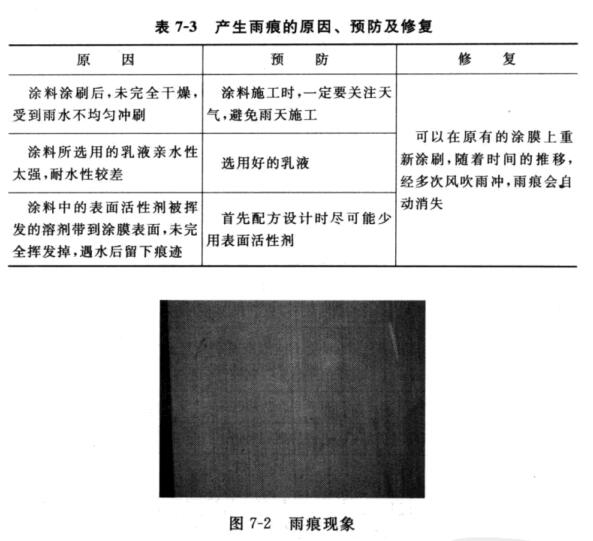

After the paint is painted, when it is washed by rain, the coating film will appear streaks like tears. The reasons, prevention and repair of rain marks are shown in Table 7-3, and the phenomenon of rain marks is shown in Figure 7-2.

3. Blistering

After the paint is painted, there is a certain amount of water vapor between the surface layer method material and the primer or the base layer, which causes the surface layer coating to partially bulge. The causes, prevention and repair of the bubbles are shown in Table 7-4. 7-3.

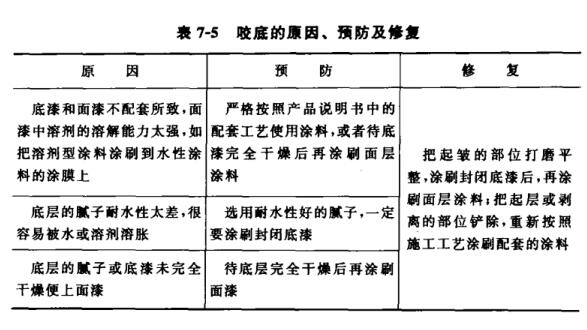

4. Bite the bottom

The solvent in the topcoat penetrates into the primer and swells the bottom layer, causing it to wrinkle, peel off, and peel off. See Table 7-5 for the cause, prevention and repair of the bottom coat.

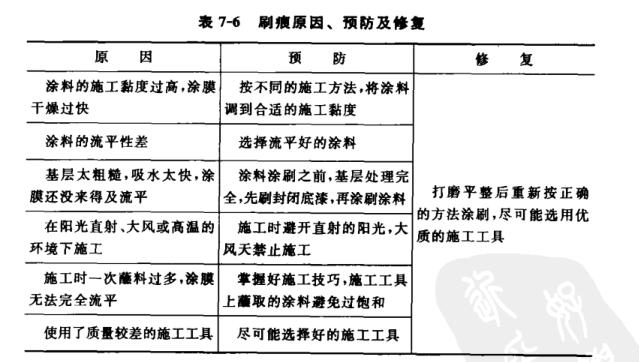

5. Brush marks

After the coating is dried, there are traces of brushes or rollers, and the causes, prevention and repair of brush marks are shown in Table 7-6.

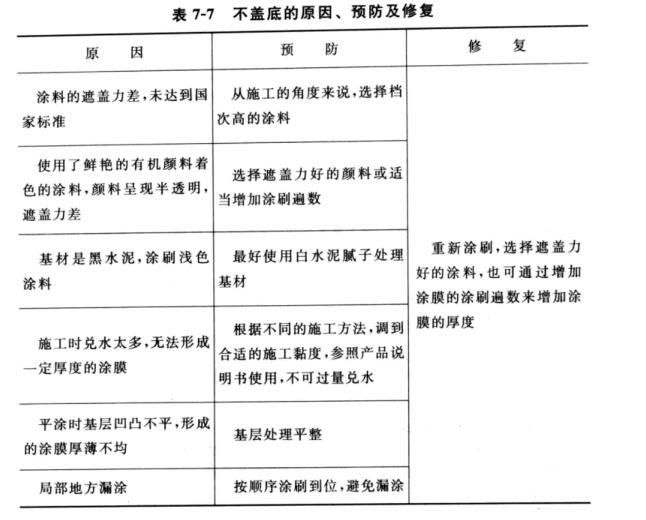

6. No bottom cover

After the paint method is applied, the paint film cannot completely cover the color of the substrate. The reasons, prevention and repair of the unfavorable base are shown in Table 7-7. The phenomenon of not covering the base is shown in Figure 7-4. (Related equipment: covering power paper)

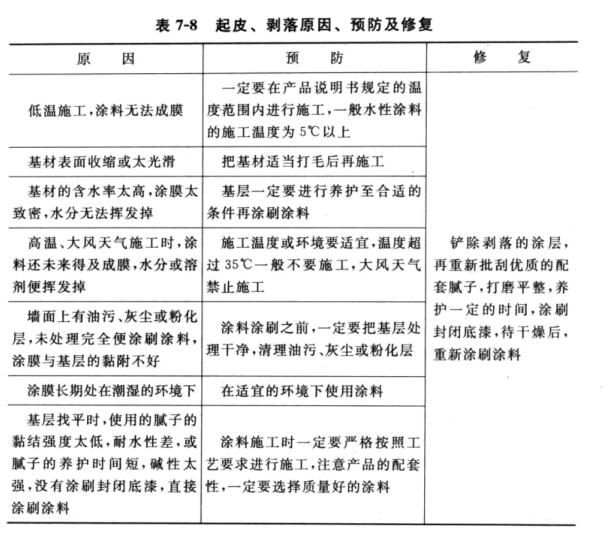

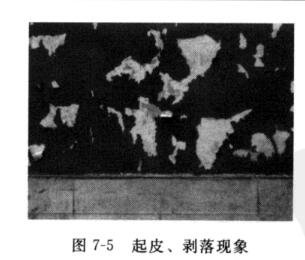

7. Rigidity, peeling off

The phenomenon of coating film forming and peeling from the substrate, the causes of peeling and peeling, prevention and repair are shown in Table 7-8. The phenomenon of peeling and peeling is shown in Figure 7-5

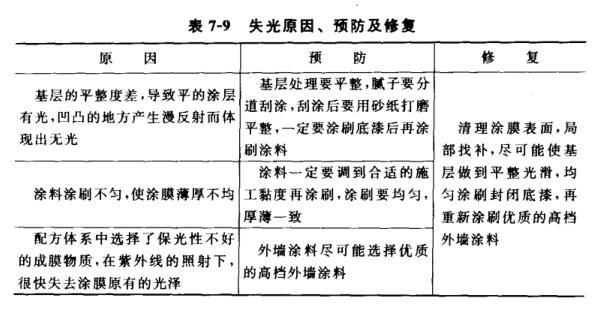

8. Lost light

Glossy paint is painted on the object, and the gloss is uneven or disappears after painting. The reasons for the loss of light, prevention and repair are shown in Table 7-9. (Related instruments: gloss meter)

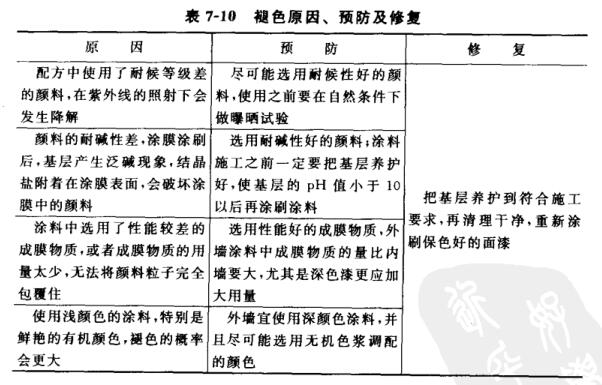

9. Fade

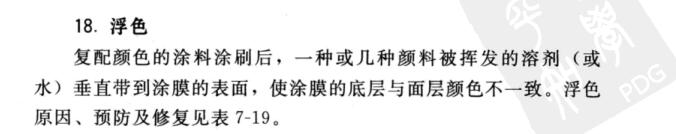

The phenomenon that the color of the coating film itself becomes lighter after the method is applied for a certain period of time, the causes of discoloration, prevention and repair are shown in Table 7-10,

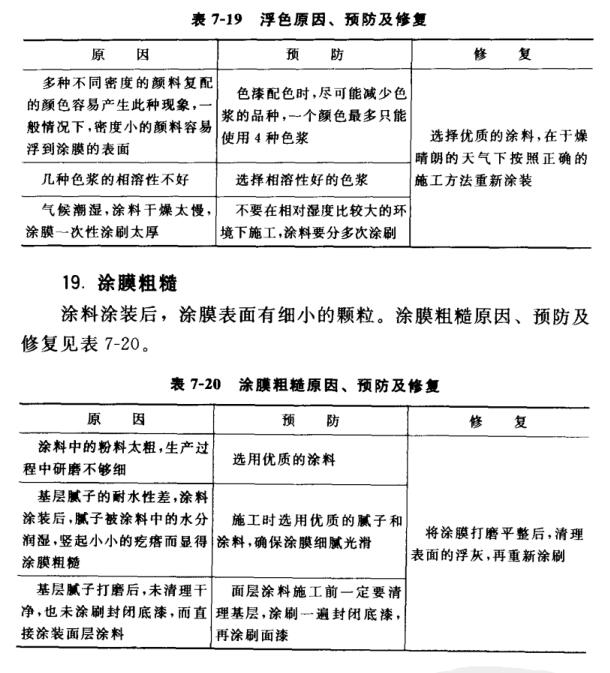

10. Pulverization

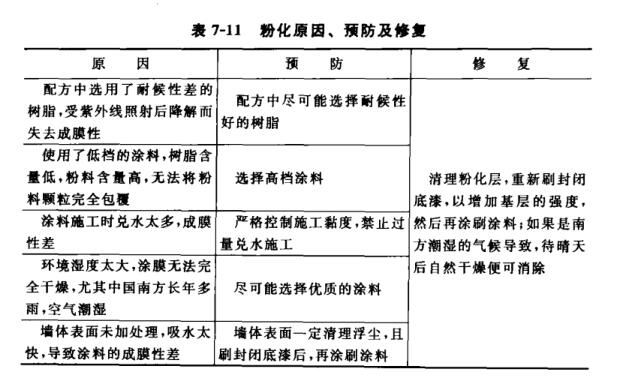

After the coating film is painted for a certain period of time, the surface shows loose and attached fine powder phenomenon. The reasons for powdering, prevention and repair are shown in Table 7-l1. (Related instruments: adhesion Tester)

13. Cracks

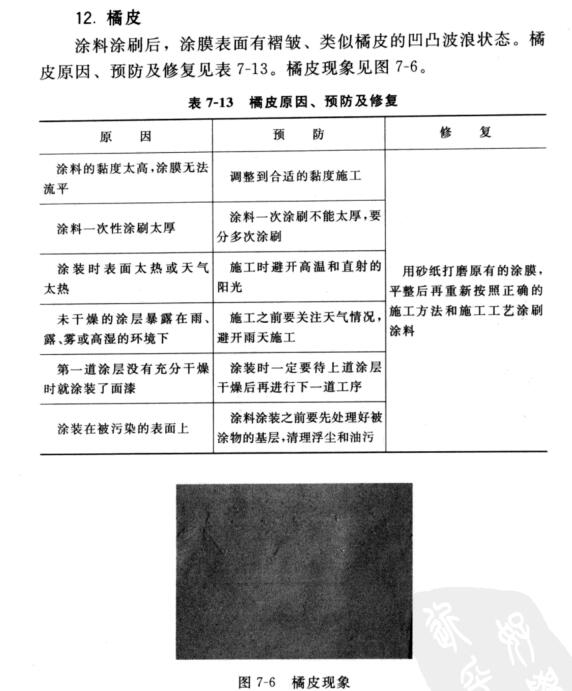

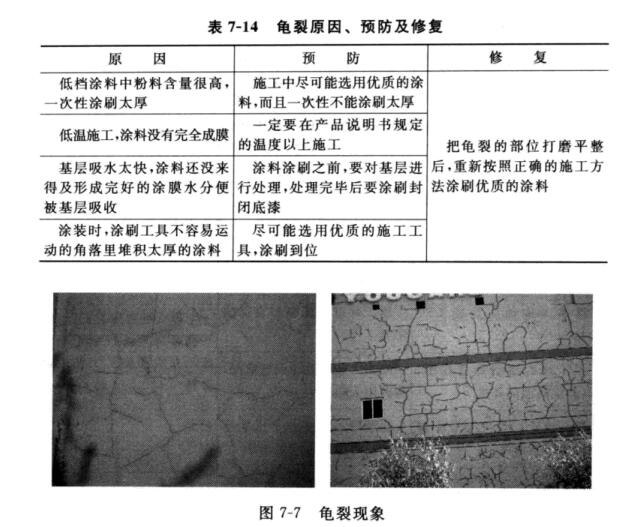

Irregular small cracks appear on the dry coating film, see Table 7-14 for coloring reasons, prevention and repair, and see Figure 7-7 for electrical phenomenon

- 1Sag problems and their solutions

- 2what is the coating Leveling and Sag resistance

- 3How to assess the sag resistance of paints and varnishes according to ISO 16862

- 4Why does the coating have orange peel defects? How to solve sagging and leakage?

- 5What is the difference between paint and paint?

- 6Wetting, coalescing and hanging of paint rheological phenomena

- 7The difference between ink fluidity and fluidity

- 8Common paint film defects and solutions of container coatings

- 9Determination of leveling and sagging of coatings