Coating powder film Cupping test

The measurement method of cupping test of powder coating film is introduced as follows:

(1) Equipment

Cupping Tester.

(2) Sample

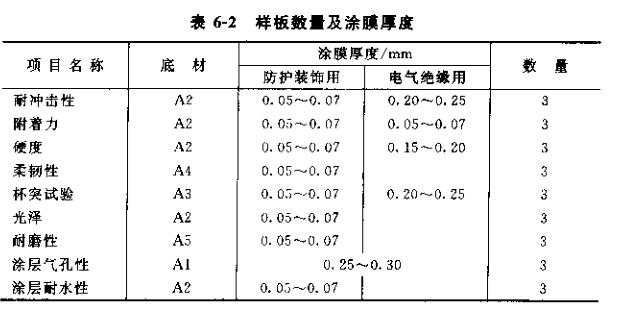

See Table 6-2, only one side needs to be coated.

(3) Test method

The test was carried out under the conditions of (23±2)°C and relative humidity of 50%±5%.

①For protective decoration samples: tighten the sample between the chuck and the base, with the coating film facing the base, and make the indenter contact with the side of the sample without the coating film (zero adjustment). Make the indenter advance at a constant speed of about 0.2mm/s. When the coating is found to have pattern or peeling through the magnifying glass, stop the machine and record the depth of the cup.

One pressure cup for each sample, and the distance from the pressure cup to the edge of the sample is at least 35mm. 3 trials were performed.

②For electrical insulation samples: Use a sharp knife to concentrically and roughly equally divide the coating film of the sample into a house shape with 3 knives, and completely cut through the coating film. Tighten the sample between the chuck and the base, with the coating film facing the base, so that the indenter is in contact with the side of the sample without the film (zero adjustment), and the center line of the indenter should pass through the center of the profile. Make the indenter advance at a constant speed of about 0.2mn/s. When it is found through the magnifying glass that any sharp corner at the center of the star is peeled off and assembled, stop the machine and record the cup pressing depth. (Related instrument: resistance meter)

One pressure cup for each sample, the pressure cup to the edge of the sample is at least 35 mm. Perform 3 trials.

- 1Determination of thermal plasticity Resin melt flow rate

- 2Molecular weight and distribution characteristics of polyester resin in thermosetting powder coatings

- 3Density Determination Method and Application

- 4Determination method of cone-plate viscometer and its application

- 5Thermal plasticity polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

- 6Determination of compatibility of powder coatings: methods, effects and applications

- 7Evaluation of flowability of powder coatings: key factors and significance

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Importance of powder coatings curing degree and detection method

-

-

-

-

-

JFL QBJ coating Cupping Tester$ 998.00

-