How to determine the porosity of coating powder coating?

This method is used to measure the number of pinholes and defects in the sample method.

(1) Instruments and equipment

DC high-voltage generator: The generator can generate DC output voltage, which can be adjusted to 1-5% and -10%, and its internal resistance should make the average value of the steady-state short-circuit current (3±0.3) mA. During the high-voltage flashover period, the maximum current value is between 10~50mA, and the pulse charge should not exceed 25x10-3mC. One of the two electrodes of the generator is connected to the high-voltage test head through a shielded high-voltage wire. , the generator shall be equipped with a light or sound device to indicate each spark discharge on the test electrode.

High-voltage test head: The test head is equipped with a protective wire to limit the current of the high-voltage inner network, and a conductive sheath connected to the protective conductor outside. (Related instrument: resistivity meter)

Electrode: The electrode is made of soft metal brush or conductive rubber. The brush should be able to cling to the surface of the sample during the test and there should be no leakage during the movement.

(2) Sample

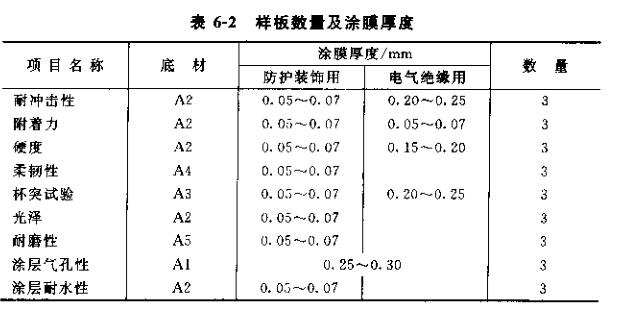

See Table 6-2.

(3) Test method

Adjust the test voltage according to the thickness of the coating to 1111 kV/mm, so that the electrode moves close to the surface of the sample at a maximum speed of 4 cm/s. During the test, the test voltage should be monitored and allowed to drop but not exceed 10%. Coating pinholes or defects are indicated by visible sparks on electrodes and optical or audible signals on equipment.

(4) Results

Indicate the number of pinholes or defects on each specimen.

- 1Overview of resistant coatings

- 2Characteristics and construction points of corrosion resistant Coatings

- 3Application of corrosion resistant coatings on reinforced concrete surfaces

- 4Technological development and application of heavy anticorrosive coatings

- 5Application and performance analysis of silicon diffusion coatings

- 6Research and application of chromium diffusion coatings

- 7High temperature oxidation and corrosion resistance performance and application of aluminum diffusion coatings

- 8Zinc diffusion coating performance process and application

- 9Chromate coating technology and its application