Coating thickness measurement technology---drip method

Spot thickness measurement is the most convenient coating thickness measurement method. Its advantage is that the instrument is simple and the method is convenient. But the disadvantage is that the measurement accuracy is low, and the general accuracy is about ±20%. At the same time, this method is not suitable for parts with complex shapes and small parts, so it is only used as a reference test method for roughly measuring the coating thickness.

1) Method principle

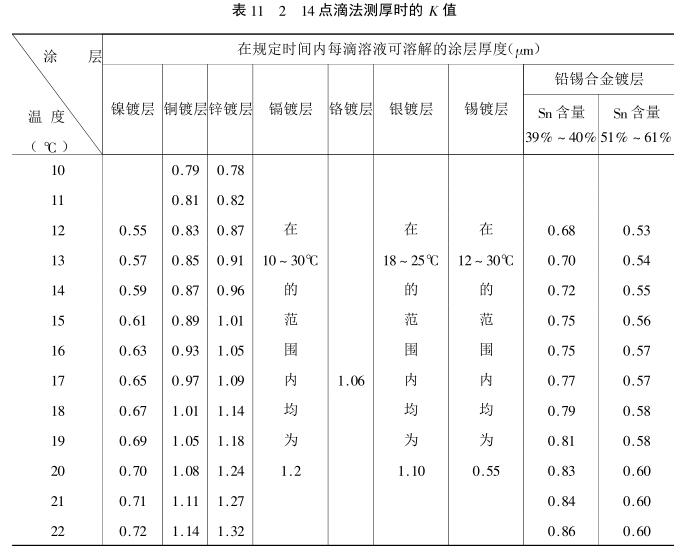

Use a solution of a certain composition to clear the solution on the surface of the coating to be tested through a pigging pipe with a tip of 1.5-2.0 mm in diameter, and keep it for a certain period of time to dissolve the coating until the coating is completely dissolved and the substrate or the underlying metal coating is exposed. The thickness of the coating is calculated by the amount of solution consumed.

Coating Thickness Calculation Formula

4) Test method and steps

(1) Before the test, select the thickness measurement part on the part to be tested, and use alcohol to remove surface oil and dirt.

(2) Use paraffin or a special pencil to draw a circle with a diameter of 5mm at the thickness measurement part.

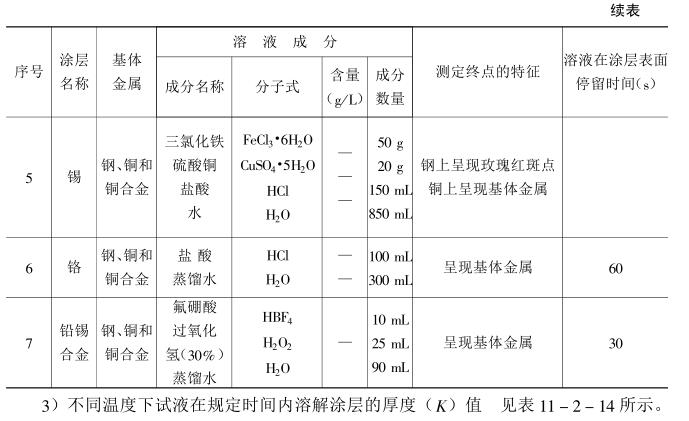

(3) According to the type of coating and substrate to be tested, prepare the corresponding test solution according to Table 11_2_13 (generally, it should be prepared now), use the pigging pipe that meets the requirements, clean up the test solution in the small circle, and keep the specified action time , absorb the test solution with filter paper, if the end point does not appear, clear the second clear test solution, keep the same time and dry it with filter paper, repeat this process until the end point appears.

(4) Record the actual consumption of test solution, and calculate the coating thickness according to the coating thickness calculation formula of this method. (Related instrument: Thickness Gauge)

(5) In general, the same method should be used to measure 2~3 places adjacent to the thickness measurement of the sample, and the average thickness should be used to represent the thickness value of the coating to be tested.

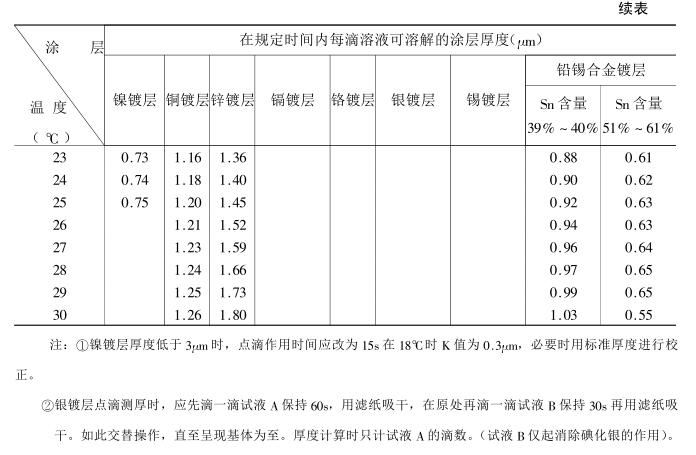

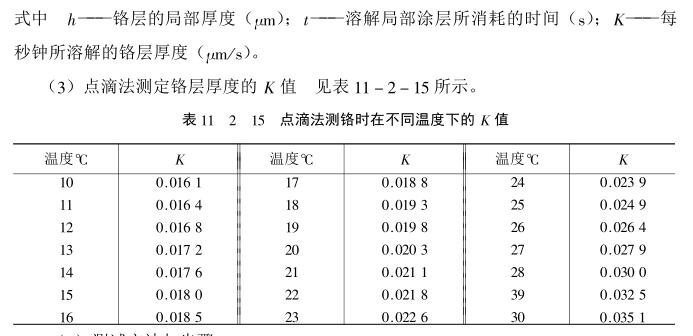

5) Determination of thin decorative chromium coatings by spot method

For thin chromium coatings on steel, copper or copper all-gold, copper-nickel substrates or undercoatings, the following method shall be used when measuring the coating thickness by the spot method.

h=t·K

(4) Test method and steps

① Before the test, use alcohol or organic solvent to remove oil and dirt on the surface of the chromium layer to be tested.

② Use paraffin wax or a special pencil to form three small circles with a diameter of 5mm at appropriate positions on the surface of the degreased chrome layer.

③Use the pre-prepared pigging tubes that meet the requirements, place the test solution and samples on the operating table, and make their temperature the same as room temperature for later use.

④ Prepare a stopwatch, use a pig to absorb concentrated hydrochloric acid, and pour a clear test coat into each wax circle, start the stopwatch immediately when bubbles start to form, stop timing when the bubbles in the circle stop and expose the bottom metal, and record the consumption time.

⑤ According to the indoor temperature, find out the K value according to Table 11_1_19, and use the formula h = t·K to calculate the thickness of the coating.

- 1Nondestructive measurement Coating thickness

- 2Principle, application and selection of traffic coatings Coating Thickness Gauge

- 3Principle, Application and Selection of Eddy current Coating Thickness Gauge

- 4Principle, Application and Type Selection of Electronic Coating Thickness Gauge

- 5Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- 6Principle, Application and Type Selection Analysis of Chrome Coating Thickness Gauge

- 7Principle, Application and Selection of Coating Thickness Gauge for inner wall of small pipe

- 8Basic principle and application scenario of steel Coating Thickness Gauge

- 9Principle and Application Analysis of Coating Thickness Gauge