Coating corrosion resistance inspection -- humidity cabinet test

The damp heat test is a method of artificially accelerating the corrosion test of the coating by simulating the environmental conditions of the coated product in which the temperature and humidity are constant or frequently alternate and cause condensation. Due to the artificially clean high temperature and high humidity conditions, the corrosion effect on the coating is not obvious, so it is generally not used as a separate coating quality inspection item, but only for product assemblies, including coatings and various metal protective layers. Comprehensive performance measurement.

1. Test set various technical parameters

The damp heat test is carried out in a damp heat Test Chamber.

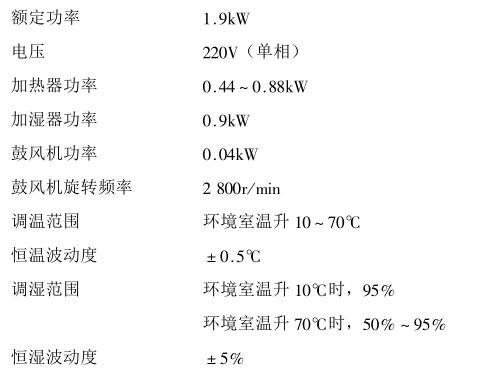

The main parameters of the domestic DL_302 temperature and humidity control box are as follows:

2. Test method

There are two common methods of damp heat test.

1) Constant temperature and humidity Test Chamber at a temperature of 4o ℃ ± 2 ℃, and a relative humidity of 95% or more. It is a test in which the product is often exposed to high temperature and high humidity conditions.

2) Alternating temperature and humidity test

(1) From 30 liters to 40 ℃, relative humidity ≥ 85%, time 1.5~2 hours;

(2) High temperature and high humidity 40℃±2℃, relative humidity 95%, time 14~14.5 hours;

(3) Cool down from 40°C±2°C to 30°C, relative humidity ≥85%, for 2~3 hours;

(4) Low temperature and high humidity 30°C±2°C, relative humidity 95%, for 5-6 hours.

It is a test under the condition that the product is exposed to condensation in an alternating environment of high temperature and high humidity.

3. Evaluation of test results

Good The color is darkened, and the coating and base metal are free of corrosion;

Qualified The corrosion area of the coating does not exceed 1/3, but the bottom metal has no corrosion except for the corners on the edges;

Unqualified The corrosion area of the coating exceeds 1/3, or the base metal is corroded.

- 1GB/T 10586-2006 Detailed explanation: Core technical indicators and acceptance specifications for damp heat Test Chamber

- 2Humidity cabinet test equipment

- 3Introduction of working principle and application of aging Test Chamber for industrial white oil

- 4Application of thermostatic aging Test Chamber

- 5Principle and application of pearlescent powder aging Test Chamber

- 6The working principle and application of rubber UV aging Test Chamber

- 7Introduction of working principle and application scope of rapid temperature change aging Test Chamber

- 8Damp heat testing chamber and low-Temperature Test Chamber

- 9Basic principle and application of water-based paints Xenon-arc lamp aging Test Chamber