Determination of Colors

Determination of chromatic colors can use simple and accurate three-color standard determination method. This method is based on the possibility of mixing light with three colors to obtain any hue. According to this principle, a Maxwellov disc is made - a "rotating disc for mixing colors" driven by an electric motor. This instrument is called a rotor Colorimeter after being improved by the Kandela times.

A simple pneumatic "spinning disk" can also be used instead of the motor; in this case, a turbine made of thin iron is driven by air (a pear-shaped rubber ball).

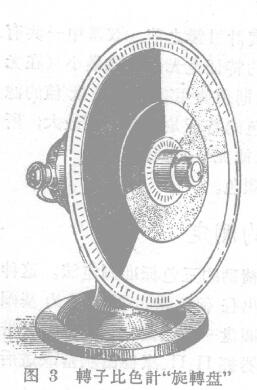

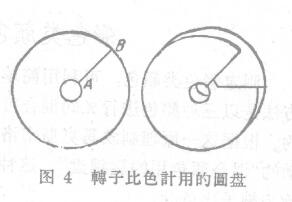

Frontal color is measured with a Hanzi Colorimeter (rotary disc Colorimeter, "rotating disc"), the main part of this instrument (Fig. 3) being a disc made of strong thick paper mounted on the shaft of a small electric motor. A disc of thick paper painted in a different color can also be mounted on that shaft in the usual way. Since the discs have section AB (FIG. 4), it is possible to insert one disc into the other, thus exposing sectors of desired size from each disc. This set of discs is mounted on the tray of the instrument. Because the area of each sector is proportional to the length of its arc when the radius is the same, the area of each sector can be measured by the percentage of the area of the circle. Arcs are measured using graduated circles in degrees (from 0 to 100) engraved on the circumference of the instrument dial. On the same axis of the instrument, a disc with a smaller diameter can also be installed. Its fan-shaped area can be measured with a smaller scale (degrees from 0 to 100). The number of revolutions of the motor should not be less than 1800 revolutions per minute. .The standard disc is made of very strong thick paper. For color color standards , gelatin solutions of various light-fast organic dyes are generally used. For white standards, sulfuric acid town is used, for gray standards, a mixture .

Frontal color is measured with a Hanzi Colorimeter (rotary disc Colorimeter, "rotating disc"), the main part of this instrument (Fig. 3) being a disc made of strong thick paper mounted on the shaft of a small electric motor. A disc of thick paper painted in a different color can also be mounted on that shaft in the usual way. Since the discs have section AB (FIG. 4), it is possible to insert one disc into the other, thus exposing sectors of desired size from each disc. This set of discs is mounted on the tray of the instrument. Because the area of each sector is proportional to the length of its arc when the radius is the same, the area of each sector can be measured by the percentage of the area of the circle. Arcs are measured using graduated circles in degrees (from 0 to 100) engraved on the circumference of the instrument dial. On the same axis of the instrument, a disc with a smaller diameter can also be installed. Its fan-shaped area can be measured with a smaller scale (degrees from 0 to 100). The number of revolutions of the motor should not be less than 1800 revolutions per minute. .The standard disc is made of very strong thick paper. For color color standards , gelatin solutions of various light-fast organic dyes are generally used. For white standards, sulfuric acid town is used, for gray standards, a mixture .

Achromatic color standards should have a dull surface; the surface must not contain any colored colors. ,, The standard Huai color should have high light resistance, that is, it will not fade after a long time of light. The use of light-resistant organic dyes as color standards is not allowed. C.JI. Shwin Yersan (C.JI.mHeepcoH) and B_n. Dimkina proposed the preparation of certain standard colors using particularly light-fast inorganic pigments. For example, when preparing yellow standards, it is recommended to use zinc chrome yellow, when preparing blue standards, use Hegu blue ultramarine (brand yKX), when preparing black standards, use charcoal black, etc.

When preparing the color standard according to Kant's step-based method 7, a colored adhesive layer must be applied to a glass plate that has been scrubbed with petrolatum oil (vaseline) and talcum powder and placed horizontally. On the dried glue layer, paste a piece of smooth and durable thin paper; when the glue is dry, tie the glued paper from the glass.

According to the opinions of C.JI. Sham Yersan and BH Somkina9, a simpler method can be used to prepare the color standard. It is to stick two strong and smooth sheets of paper together with a wood glue solution (100 grams of glue, 150 grams of water, 10 grams of glycerin), then stack several sheets of paper together and put them on a press for rolling. After drying, apply and cover the paper sheet with a color glue layer made of a suitable pigment (the pigment is miscible with 3% gelatin solution). After the color paper is dried, cut it into a circle with a diameter of 20 cm.

The graduation of the color standard is based on the three-color ratio in advance. For this reason, the three-color circles painted with red, blue and green with larger diameters (the color should be as saturated as possible, see the method for making it) are installed on the shaft of the motor. On this axis, a circle with a smaller diameter is also placed on which the color needs to be determined. The size of the red, green and blue sectors is properly selected by starting the motor, so that the color tone formed when the large circle rotates is completely similar to the color tone of the small circle.

For a complete determination of the color being tested, it is necessary not only to make the circles equal in hue, but also to make them identical in lightness and saturation. Therefore, it is necessary to put the black circle on the inner or outer disk, or put a circle of one of their main color classes on the inner disk.

After a series of trials, when the large disk and the small disk show the same color, immediately measure the area of each sector. The measured color is represented by the sum of the sector areas. Using the aforementioned Colorimeter, the hue, brightness and saturation of the tested color can be quantitatively measured. As MM Gurevic pointed out, in order to ensure the reliability of the measurement of this disc Colorimeter, it is necessary to pay sufficient attention to the light source used for the illumination of the disc surface as for other precision instruments.

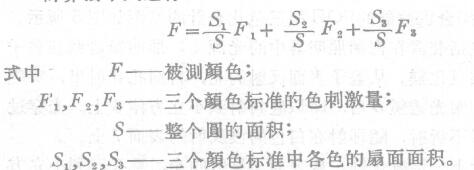

When measuring on a disc Colorimeter, the calculation is carried out as follows. That is, the amount of chromatic stimulation of each color is multiplied by the relative area occupied by this color on the circle.

The calculation is carried out as follows:

Examples of calculations for the comprehensive analysis of pigment color using a disc Colorimeter ("rotating disc") are cited in Fedorov S.

- 1How the Colorimeter works

- 2Determination of the color of transparent liquids with a Roviben Colorimeter

- 3Test method for color of adhesive resin - Platinum cobalt colorimetric method

- 4Colorimeters vs Spectrophotometers: Understanding the Differences Between Color Measurement Techniques

- 5Use of Colorimeters

- 6The principle and use of Colorimeter

- 7What is a Colorimeter? Types of Colorimeters

- 8What types of Colorimeters are there?

- 9Functional Comparison of Colorimeter and Spectrophotometer