Quantitative testing of coating bonding force--tensile test method

The quantitative test method of coating binding force is complex, cumbersome, and generally cannot be carried out directly on the sprayed parts, but quantitative test can provide certain measurement data, which is more important than qualitative test for testing and comparing the bonding force of various coatings. The exact coating bonding strength is the bonding force per unit area of the coating. Coating bonding strength includes tensile strength, shear strength and compressive strength, which are determined by tensile test, shear test and compression test respectively.

1) Tensile test method

Coating tensile strength is the ultimate ability of the coating to withstand tensile stress in the normal direction (perpendicular to the coating surface), which is an important indicator for evaluating the coating's bonding force. In the test, use the test tool or equipment to make the sample bear the tensile force perpendicular to the coating surface until the sample is pulled apart, that is, the coating is peeled off, record the load at the time of failure, and divide the load by the cross-sectional area of the sample value, the tensile strength of the coating can be calculated. as follows:

According to the different test equipment and samples, there are various specific methods for tensile testing. A few are listed below.

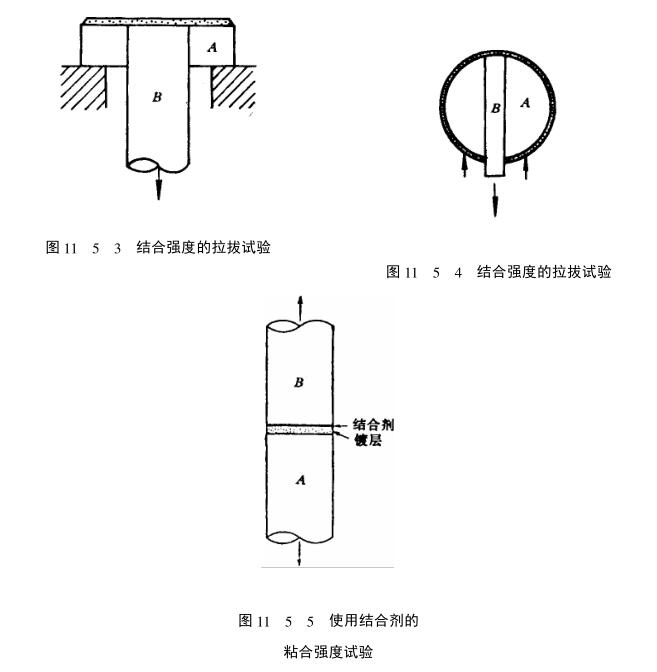

(1) Pull-out test

As shown in Figure 11_5_3, a hole is opened in the center of the sample A, the piston 9 is slipperily fitted with the center hole, and the top surface of the sample A and the upper end surface of the piston are in the same plane before spraying, and then the test piece is supported from below. In the same way, pull the piston vertically downward until the coating on the end surface of the piston and the sample is destroyed.

Samples of this shape are suitable for simulating the bonding strength test of flat sprayed parts. In this kind of test, even if the precision of the sliding fit between the piston and the sample is very high, a bridge-shaped coating will be formed between the two planes to cause stress concentration and become a weak part of cracking. Therefore, the measurement obtained by this method The value is low.

In addition, for cylindrical sprayed parts such as shafts, as shown in Figure 11_5_4, a hole can be opened on the cylindrical test piece A to allow the piston g to pass through, and the curvature of the upper surface of the piston is the same as that of the cylindrical test piece to form the same Spray the curved surface, then support the cylindrical specimen from below, pull the piston B vertically downward until the coating on the upper surface of the piston is destroyed, measure the force, and then calculate the bonding strength of the coating according to the cross-sectional area of the piston .

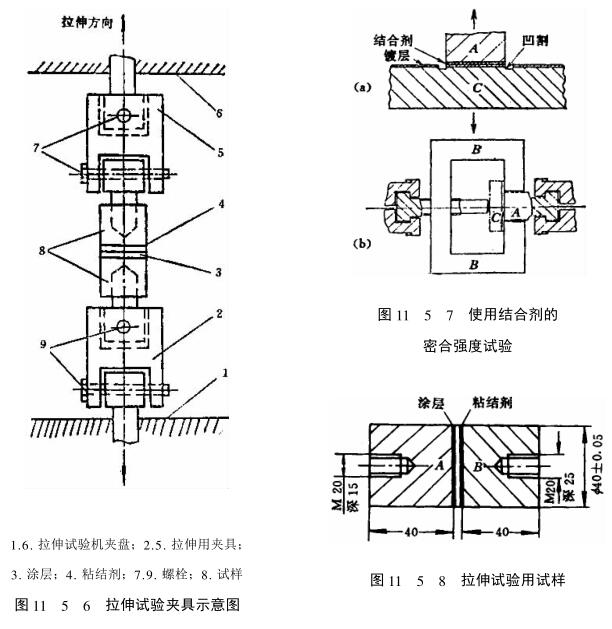

(2) Pull-out test using adhesive

As shown in Figure 11_5_5, the end surface of the cylindrical sample A is roughened and then sprayed to form the coating required by the test. The thickness of the coating depends on the requirements (the minimum thickness is generally not less than 0.4mm). At the same time, roughen the end surface of the cylindrical sample g of the same material and size, and coat a thin and uniform layer of adhesive on the coated surface of sample A and the roughened surface of sample 9, and place the test piece Place sample A on sample 9, make the axes overlap, and apply appropriate pressure to make it fully bonded. Do not allow air bubbles to remain in the adhesive. The overflowing adhesive should be removed, and the pull-out test should be performed after curing.

The equipment used for the test can be any type of Tensile Testing Machine that can meet the static cutting conditions. The fixtures used in the test are shown in Figure 11_5_6 and Figure 11_5_7. Samples A and 9 shown in Figure 11_5_8 are both processed into a ticket hole in the center of the end face of the non-adhesive surface, so that it can be screwed into a special tensile fixture. In the sample A shown in Fig. 11_5_7, the lower end surface of the sample A is sandblasted and bonded with the coating surface of the test piece g with an adhesive. Clamp it with a special jig and test it on a Tensile Testing Machine.

After the test, use the cross-sectional area of sample A to remove the tensile load when the coating is damaged, which is the bonding strength of the coating. Such a pull-out test using an adhesive is not suitable for coatings having a bond strength above that of the adhesive. (Related instrument: Tensile testing machine)

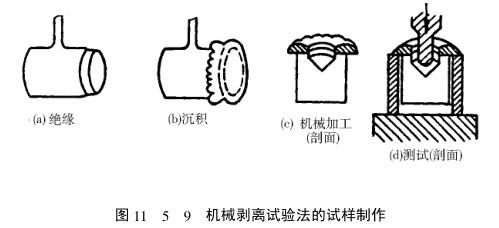

(3) Mechanical peeling test method

Insulate a bar-shaped sample of a certain specification except one end face, and then electroplate the end face of the bar. It is required that the plating layer has sufficient thickness and the plating layer develops laterally beyond the insulating layer. Then the sample is machined into a boss with radial diffusion at the end of the rod, and the lower surface of the boss is in the same plane as the original end face of the rod end. The processed sample is placed on a single cylindrical fixture, and a special testing machine is used to load the sample downward until the coating at the end of the sample bar is peeled off. According to the tensile force required for peeling and the area of the coating, the bonding strength of the coating can be calculated.

The preparation and loading of mechanical peel test specimens are shown in Figure 11_5_9.

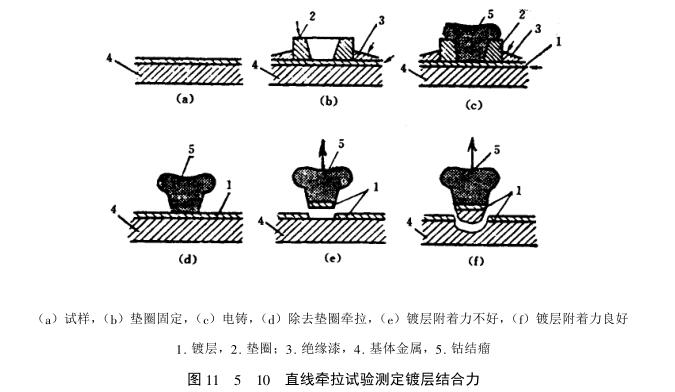

(4) Straight line tension test method

The linear stretch test can be carried out directly on the plated parts. First, on the coating surface of the test piece, use a non-conductor pad to fix it on the measured part, and add an insulating layer on the coating surface outside the pad, and then electroform cobalt or other metals on the coating inside the pad, after a certain period of time , a metal nodule is formed along the inner wall of the pad on the plating layer. After the electroforming is completed, the pad is removed, the insulating layer is removed, and the test piece with the metal nodule cast is placed on a special Tensile Testing Machine. The layers are pulled to fracture as shown in Fig. 11_5_10. The bonding strength of the general layer can be calculated according to the force applied when the general layer is peeled off and the bonding area of the general layer.

- 1Tensile machine application in various industries

- 2Technical analysis of key parameters of Tensile machine: Scientific selection from force measurement accuracy to Power system

- 3Tensile machine purchasing guide [dry version]

- 4Talking about the performance test of epoxy resin film coated on PET

- 5ASTM D5019 Single-layer roofing film reinforced CSM board (chlorosulfonated polyethylene (PE)) standard interpretation

- 6Common problems and solutions in tensile testing

- 7What is tensile strength testing and which products can be tested?

- 8Factors Affecting the Performance and Accuracy of Tensile Testing Machines

- 9Classification of Tensile Testing Machines

-

-

-

CHINA NBC-1024-2 Tensile Tester 5T$ 6635.00

-

-

-