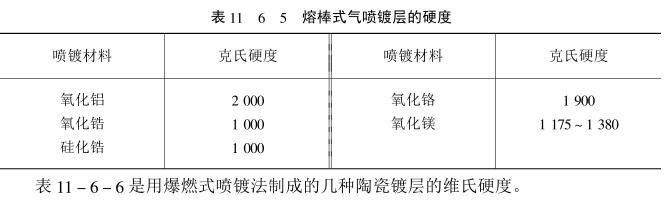

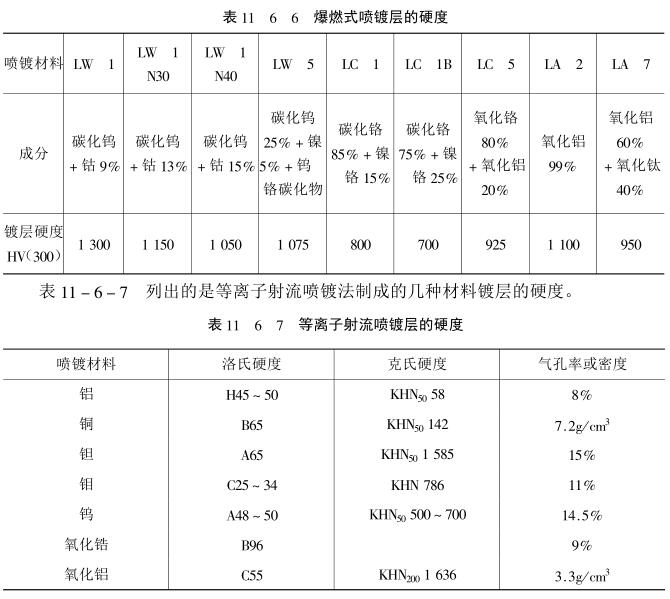

Hardness of several coats

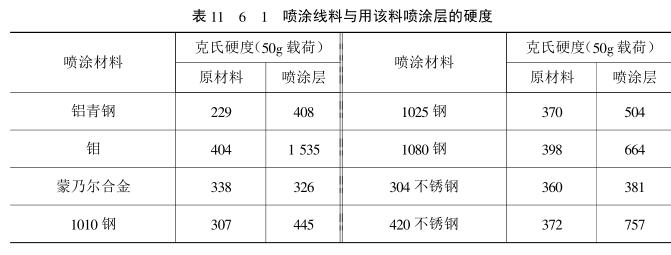

Hardness is one of the important mechanical properties of the coating. It is related to the width, strength and service life of the coating during use. The hardness of the coating is related to the spraying method and spraying conditions (spraying equipment, spraying materials , spraying temperature) and other factors. Due to the different spraying methods and spraying conditions, the hardness of the coating is usually different, because the hardness of the coating is determined by the size and structure of the finished particles of the coating, the number and size of the pores , oxides and other compounds, etc., and the difference in spraying method or spraying conditions often causes the difference in the above factors, resulting in the difference in the hardness of the coating. The hardness of the material is high, which helps to enhance the damage performance of the coating, as shown in Table 11_6_1 is the comparison between the microhardness of the sprayed wire material and the microhardness of the particles of the air sprayed coating with this wire material. (Related instrument: Hardness Tester)

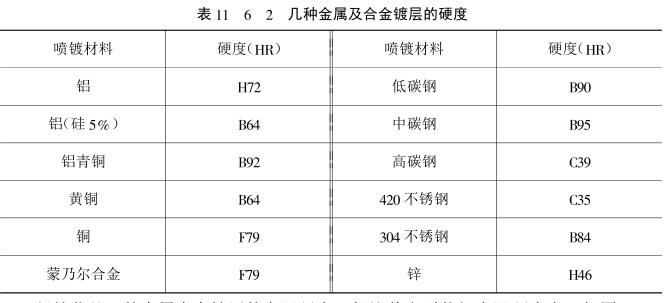

Table 11_6_2 shows the average hardness of coatings made of several practical metals and alloy materials under commonly used spraying conditions

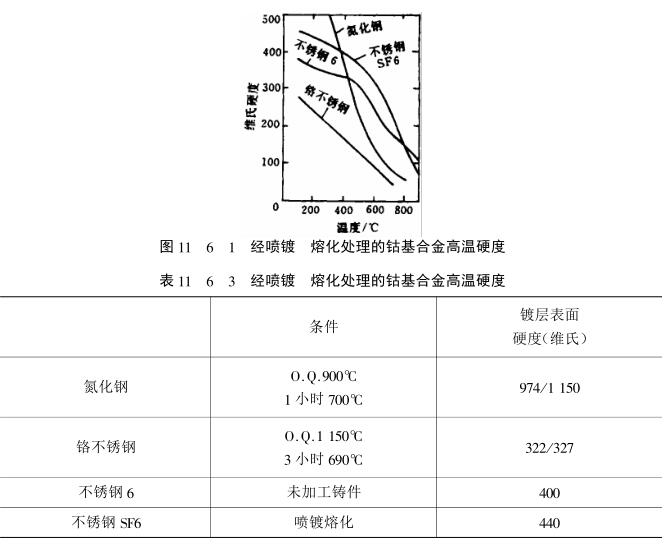

The high-temperature hardness of the melt-treated metal alloy coating is generally higher than that of other heat-resistant steels. Figure 11_6_1 and Table 11_6_3 show the relationship between the high-temperature hardness of the melt-treated cobalt-based alloy coating and other heat-resistant steels. Comparison of high temperature hardness of steel. Here, a Vickers Hardness Tester is used, the load is 20kg, the loading speed is 8 seconds, and the results are measured in a vacuum of 0.133 ~ 0.532Pa.

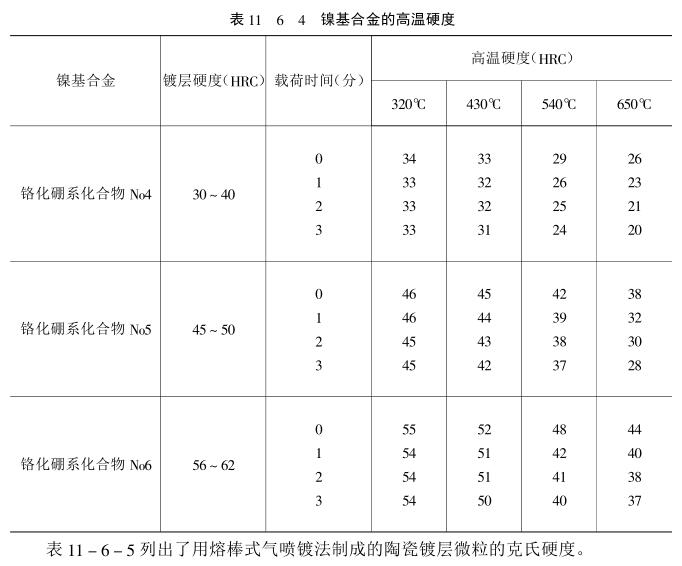

The self-fluxing alloy coating after melting treatment has a wide range of hardness due to the complex composition of the alloy, and the self-fluxing alloy material mixed with tungsten carbide powder can form tungsten carbide (Hv2 1oo~ 2 9oo) distributed on the surface of the blank. In addition, Table 11_6_4 shows the high-temperature hardness measurement results of three nickel-based alloys at 65°C under different loading times. At high temperatures, the hardness of these materials are all It is only slightly reduced, and it has the characteristic of returning to the original hardness when it is cooled to room temperature after heating.

- 14 test types for measurement of coating strength

- 2How to use the Dutch TQC coating hardness test pen SP0010

- 3Why measure the strength of protective coatings?

- 44 test types to test coating strength

- 5Application of Pendula Hardness Tester in determination of automobile coating Hardness

- 6Hardness test method of surface coating

- 7Pencil Hardness Testing of Modified Graphite Nanosheet Coating

- 8A Foreigner's Understanding of Coat Hardness

- 9Hardness measurement of coating applications