Bending rate inspection method of coating internal stress

Curvature test method

This method is suitable for testing residual stress in thermal sprayed coatings. Due to the different shapes of the samples, they can be divided into rectangular samples and circular samples, so the specific methods are also different. (Related instrument: bending rate Tester)

(1) Rectangular sample

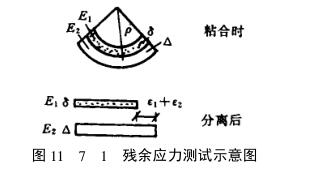

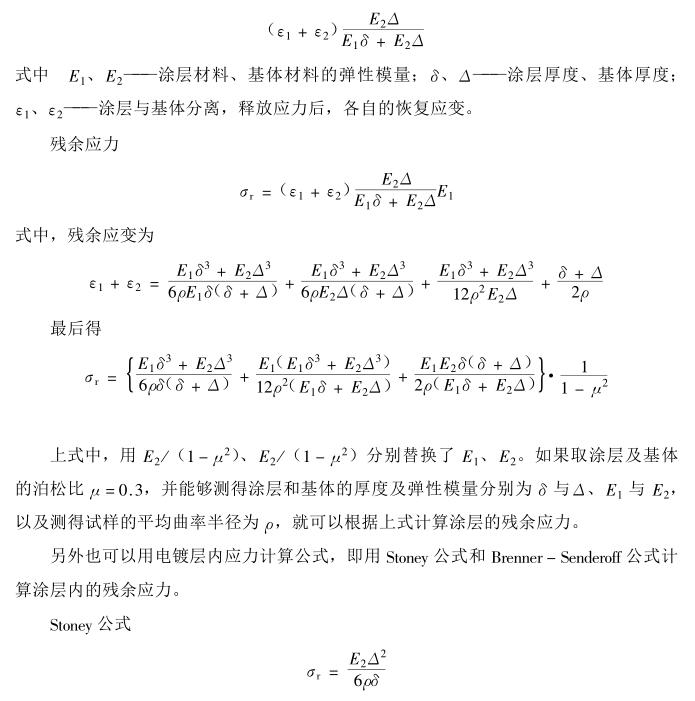

On the rectangular test plate, the material is sprayed, the bending deformation occurs, the radius of curvature of the two materials is measured respectively, and the arithmetic average value is taken, then the coating is separated, the internal stress is released, the residual strain is measured, and the residual stress is finally calculated. As shown in Figure 11_7_1.

When doing the bending test of the sprayed coating of the sample, it is assumed that the bending meets the pure bending assumption in material mechanics, that is, the plane section assumption. The same section remains unbent before and after deformation, only rotates, and does not displace. It can also be explained that the matrix, the coating, and between them maintain a layered state, the layers are not dislocated, and the upper and lower layers do not separate.

(2) Ring sample

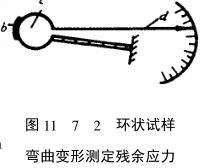

As shown in Figure 11_7_2. Apply coating b to one side of the annular base c (opening), and after cooling, the ring of the base is deformed due to the effect of residual stress, which drives the pointer d to rotate, and calculates the magnitude of bending deformation and residual stress according to the magnitude of the rotation reading.

- 1Test of Coating Internal Stress

- 2Determination method of internal stress of coating

- 3Resistance strain test method for coating internal stress

- 4Spiral cissing inspection method for coating internal stress

- 5Deflection method inspection method of coating internal stress

- 6What is coating force?

- 7Coating internal stress and inspection

- 8Coating internal stress test - resistance strain method

- 9Coating internal stress test - bending rate inspection method