Coating wear resistance inspection -- Abrasive wear test method

The amplitude inspection of the coating is generally to simulate the working conditions of wear, and conduct a comparative friction and wear test to evaluate and inspect the amplitude of the coating. In practical applications, there are many types of wear, and there are many corresponding wear test methods. Commonly used are the following.

Abrasive Wear Test

There are generally two types of abrasive wear tests, one is the rubber wheel abrasive wear test, and the other is the pin-on-disk abrasive wear test.

(1) Rubber wheel abrasive wear test

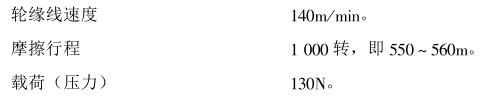

Figure 11_7_4 shows a schematic diagram of the test principle. Abrasives with a certain particle size fall between the rotating grinding wheel and the square sample through the feeding tube at a fixed rate. The rim of the grinding wheel is rubber with a specified hardness. The sample is pressed against the rotating grinding wheel with a certain pressure by means of the I-bar system, and the coating surface of the sample meets the rubber wheel surface at an angle. The direction of rotation of the rubber wheel should make the direction of movement of the contact angle consistent with the direction of abrasive flow. During the rotation of the abrasive, the abrasive produces low-stress abrasive wear on the specimen. After a certain rubbing stroke, measure the weight loss of the sample, that is, the reduction of the coating, and use this to evaluate the amplitude of the coating. (Related instruments: Abrasion Tester)

A typical sample is a rectangular test piece of 50mmx75mm, with a thickness of 10mm. Prepare a coating on its plane, and use a surface Grinder to grind the coating. The grinding direction should be parallel to the length of the sample. Make the coating surface free of any attachments or defects. Generally used test parameters are:

(2) Pin-disc abrasive Grinder test

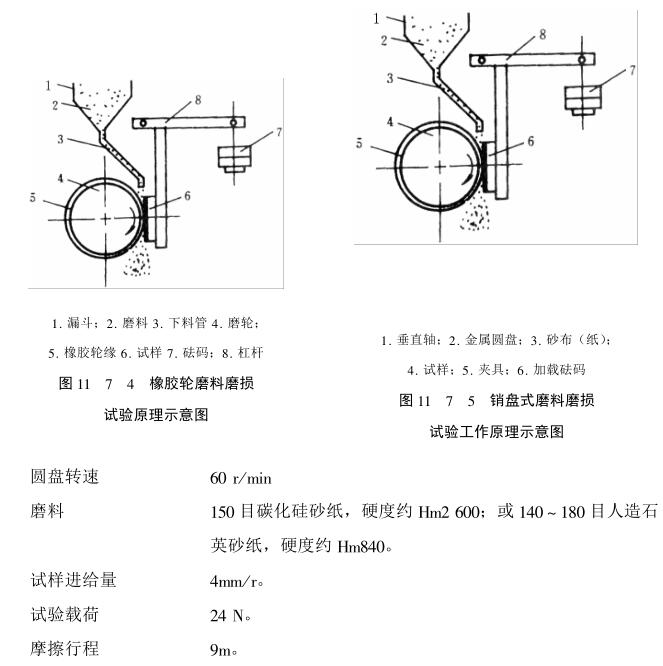

Figure 11 _7_5 is a schematic diagram of the working principle of the pin-on-disk abrasive Grinder test. Mount sandpaper or emery cloth on the disc as an abrasive for the testing machine. The sample is made into a pin type, and is pressed on the disc sandpaper under a certain load pressure, and the coating surface of the sample is in contact with the disc sandpaper. The disc rotates, and the sample moves linearly along the radial direction of the disc. After a certain rubbing stroke, measure the weight loss of the sample, that is, the wear amount of the coating, so as to evaluate the wear resistance of the coating. The test equipment is the domestic pin-disc type ML_10 abrasive Grinder testing machine. The sample adopts a cylindrical shape with a diameter of 4mm. The coating is prepared on one plane end of the test, and the coating is ground and cleaned to make the surface free of any defects and attachments (relevant instrument: adhesion Tester). The end face should be perpendicular to its axis. The suggested test parameters are as follows:

- 1Working principle and application of UV coating Cupping testing device

- 2Application of shakeout Tester in organic polymer film abrasion resistance testing

- 3Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 4Paint film abrasion resistance and test method thereof

- 5Polyethylene (PE) coating indentation hardness inspection and its importance in pipeline corrosion protection

- 6Paint film abrasion resistance and its test method - rubber abrasive wheels method

- 7Determination of abrasion resistance of paint film

- 8Determination method of paint film abrasion resistance and its importance

- 9Coating performance testing: the key to ensuring quality coatings