Coating wear resistance inspection -- friction and wear test

The relative movement of various friction pairs produces wear, and there are many factors that affect the wear, such as the material and surface shape of the parts, the movement form of the friction pair, the working conditions and the lubrication method. Therefore, it is difficult to evaluate the wear resistance of this type of coating. Generally, the wear resistance of the coating should be tested by simulating the actual working conditions as much as possible.

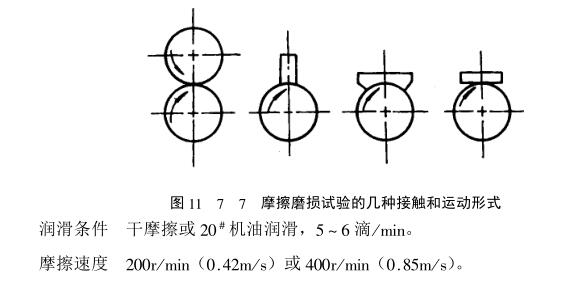

Generally, the domestic MM_200 wear testing machine can be used in the laboratory. The sample is made into a ring shape of 40mmx10mm, and a ring with a width of 9mm and a depth of 0.5mm is pre-processed on the ring surface, and then various coatings are made on the ring, and the ring surface is rounded to the sample size on a grinding machine, and cleaned. Test after cleaning. There are four kinds of accessories that form the friction pair, as shown in Figure 11_7_7, which respectively form four contact and motion forms with the sample coating. The material of the accessories can be selected from Gcr15 or cast iron, or the materials of the accessories that meet the actual working conditions. During the test, dry friction or lubricated friction can be adopted respectively, and different friction speeds can also be adopted. After the test, measure the weight loss of the sample, that is, the reduction of the coating. According to the test results of each group of friction pairs and conditions, the wear resistance of the coatings was compared. Generally, the following test parameters can be used. (Related instruments: Abrasion Tester)

- 1Working principle and application of UV coating Cupping testing device

- 2Application of shakeout Tester in organic polymer film abrasion resistance testing

- 3Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 4Paint film abrasion resistance and test method thereof

- 5Polyethylene (PE) coating indentation hardness inspection and its importance in pipeline corrosion protection

- 6Paint film abrasion resistance and its test method - rubber abrasive wheels method

- 7Determination of abrasion resistance of paint film

- 8Determination method of paint film abrasion resistance and its importance

- 9Coating performance testing: the key to ensuring quality coatings