Introduction to mass inspection of Container coatings

Although container coating is a fine chemical product, it is a warm compound composed of different chemical products. Container coating is a material for containers, so its performance represents its use value, and it is comprehensive and widely used. The scope and long-term use value, the performance of the coating product firstly includes the performance of the coating product before it is used or the performance of the original state of the coating, which means the performance and quality of the coating as a commodity in the storage process The second is that the paint should have various properties when used, or the construction performance of the paint, which means the method of use of the paint, the conditions of use, the conditions required for the formation of the paint film, and the performance of the paint in the process of forming the paint film. According to the characteristics of container coating and coating process, the following three quality inspections are required:

1. Konstandt laboratory certificate

Container coatings need to have a Kontandl test certificate. Although it has been clearly pointed out in Chapter Two, in order to ensure the quality of container materials, the International Container Standardization Committee has uniform regulations on the identification and testing of container coatings. According to the American material testing standards and testing Method, through 13 tests of 8 items of Konstandl Laboratory Company, with a total score of more than 120 points (out of 130 points). Only after the laboratory issues a certificate of conformity can this container coating be used in the manufacture of 1s0 standard containers, all Paint companies and container factories need to abide by this regulation. Container paint manufacturers need to have a variety of supporting Kon, andt laboratory accreditation reports before they can start container sales; when container manufacturers manufacture lSo international standard containers, You can only choose paint manufacturers with Konlandt certificates and corresponding matching materials.

Second, the physical properties of container coatings

The physical properties of coatings can directly reflect the quality of coating products. In the accreditation report of Kontandt Laboratory, the coating hardness, impact resistance, coating flexibility, adhesion, aging test and corrosion resistance test have been tested and certified. There is no need to test these items. (Related instruments: aging Test Chamber)

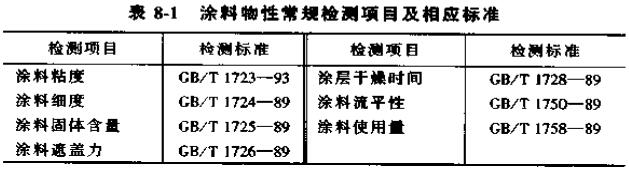

For the physical properties of container coatings, such as viscosity, fineness, solid mass, theoretical spreading rate, hiding power, dry operation time, etc., it is not only the technical index specified by the paint factory according to the product standard, but also the standard during the construction of the law. Process parameters. my country's Sino-foreign joint venture container coatings have passed the quality certification of 1SO9000, and all have product technical standards for container coatings. At present, the items and corresponding standards of routine inspection and elimination of paint physical properties in my country are shown in Table 8.1.

In the second chapter and the third chapter, the author has analyzed the glossiness (related instrument: gloss meter), volume solid content, theoretical coating rate, flash point, density, drying time (related instrument: drying time Tester) and other physical indicators. After a detailed introduction, only the three items of viscosity, fineness and hiding power are supplemented (see the instructions of the paint supplier for details).

- 1Factors Affecting Coating Viscosity

- 2Several common methods for testing coating flexibility

- 3What factors affect the flexibility of the coating?

- 4What is coating flexibility? (test principle)

- 5Coating viscosity determination and viscosity influencing factors

- 6Paint viscosity

刘登良 - 《《涂料工艺》》

- 7Determination of coating fineness

- 8Determination of paint viscosity

- 9Detection principle of coating fineness and scraper Fineness Meter