Determination of Pigment Dispersion by Dry Sieve Method

Weigh 10 grams of pigment (2 grams if it is carbon black) on an industrial balance and put it on a sieve. The number of holes in this sieve should meet the requirements of the technical conditions. The sieving of pigments is carried out by hand shaking method or mechanical vibration method (related instruments: disperser, agitator). When the sieve is shaken on a smooth paper sheet for half a minute, and no pigment particles are found falling on the paper sheet through the sieve holes, the sieve movement can be stopped. The remaining pigment on the sieve is collected on the watch glass with a soft brush and weighed.

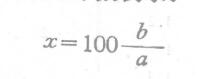

The residue on the joint can be expressed as a percentage by the following formula:

In the formula:

X--% of the residue on the sieve;

a—grams of the total weight of the pigment sample;

b - grams of pigment residue that did not pass through the sieve.

If the maximum sieved amount is taken as 100%, the difference between the two measurements shall not exceed 10%.

- 1How to Measure Pigment Dispersion on Microscope?

- 2Determination of dispersion by dry sieving and wet sieving methods

- 3Determination of Pigment Volume

- 4Determination of Pigment Dispersion with Dry Sieve Vibrator

- 5Determination of Pigment Dispersion by Wet Sieve Method

- 6Determination of Pigment Dispersion by Sieve Analysis