What are the functions of Perovskite Film Applicators?

Perovskite film

Perovskite solar cells are a new type of high-efficiency solar cells, and its high efficiency and low cost have become the focus of attention. Film is one of the key steps in the preparation of perovskite solar cells. Film is to uniformly Spreader the perovskite material solution on the substrate to form a layer of perovskite film, and then fix the film on the substrate by drying and other processes, so that the key component of perovskite solar cells can be prepared - the photoelectric conversion layer. The photoelectric conversion layer can convert solar energy into electricity, so its mass is related to the conversion efficiency and stability of perovskite solar cells. So film is a necessary step to prepare efficient and stable perovskite solar cells.

Perovskite film characteristics

Perovskite is a substance that is easily oxidized, so it is necessary to avoid oxidation reaction with air during the preparation process. This is because the structure of perovskite contains a certain amount of titanium valence and iron valence ions, which are easily oxidized in the air to form oxides, resulting in changes in the structure of perovskite and loss of original photoelectric conversion performance. At the same time, oxidation will also lead to rough and uneven surface of perovskite films, affecting the performance of perovskite solar cells.

Therefore, the preparation of perovskite solar cells needs to be carried out in an inert gas environment, or in an oxygen-free environment such as vacuum or nitrogen to avoid oxidation reactions with air. In addition, attention should also be paid to maintaining an oxygen-free environment during the preparation of perovskite materials to avoid oxidation of perovskite materials. By strictly controlling the preparation conditions, perovskite solar cell materials with higher mass and better stability can be prepared.

Perovskite film solutions

The main function of filling nitrogen with aerated knife is to block air with nitrogen to avoid oxidation reaction caused by contact with air during the preparation of perovskite solar cells. In the process of preparing perovskite solar cells, the process of Spreader perovskite materials needs to be carried out in an inert gas environment, such as preparation in an oxygen-free gas environment such as vacuum and nitrogen. Because nitrogen is inert, it can effectively block oxygen in the air. Therefore, when Spreader perovskite material is used, nitrogen is used to discharge the air in the aerated knife, which can effectively reduce the contact between the air and the perovskite material and avoid the oxidation reaction of the material. This can ensure the mass and performance of the perovskite solar cell material and improve the conversion efficiency and stability of the perovskite solar cell.

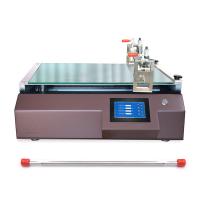

What is Perovskite Automatic Film Applicator?

Perovskite-specific Automatic Film Applicator is a device for the preparation of perovskite solar cells with the following main functions:

Spreader perovskite precursor solution: Spreader the perovskite precursor solution uniformly on the conductive substrate material to form a perovskite film.

Drying film: Spreader perovskite precursor film is dried using a Hot Plate or oven to form perovskite grains.

Spreader electron transport material: The electron transport material Spreader is used on the perovskite film to improve the electron transport efficiency and stability of the battery.

Drying the electron transport material: Spreader's electron transport material is dried to promote the bonding between the electron transport material and the perovskite film.

Spreader anode material: Spreader the anode material on the electron transport material for the anode reaction of the battery.

Drying anode material: Spreader anode material is dried to form an anode electrode.

Preparation of packaged devices: The prepared solar cells are packaged in Glass or polymer packaged devices to form a complete solar cell module.

Particularly important is that the perovskite-specific Automatic Film Applicator provides the function of air knife filling with nitrogen, thereby isolating the oxidation of the perovskite material caused by air. It is mainly used to prepare high-efficiency perovskite solar cells, with functions such as Spreader, drying, electron transport material Spreader, anode material Spreader, etc. Automatic Film Applicator has high work efficiency, easy operation and high degree of automation, which can greatly improve the preparation efficiency and mass of perovskite solar cells.

Differences from Traditional Automatic Film Applicators

Compared with the general Automatic Film Applicator, the Perovskite-specific Automatic Film Applicator has some functional differences in the following aspects:

Different film materials: Perovskite-specific Automatic Film Applicator is used to prepare perovskite solar cells, and the film materials used are different from those of general Automatic Film Applicators.

The Spreader method is different: Perovskite-specific Automatic Film Applicator adopts special Spreader methods such as air knife nitrogen filling and air isolation to obtain more stable performance films.

Drying methods are different: Perovskite-specific Automatic Film Applicators need to use high temperature and high vacuum to dry the Spreader film to form perovskite grains.

Different operation control methods: Perovskite-specific Automatic Film Applicator requires stricter operation control, such as Spreader speed, temperature, air pressure and other parameters to obtain a more stable and efficient Spreader effect.

Different uses: Perovskite-specific Automatic Film Applicator is mainly used to prepare perovskite solar cells, while the general Automatic Film Applicator can be used to prepare films of various materials, such as Spreader Plastic films, metal thin films, etc.

钙钛矿涂膜注意事项

使用钙钛矿涂膜机制膜打样时,需要注意以下几个问题:

涂膜材料的选择:钙钛矿涂膜机专门用于制备钙钛矿太阳能电池,所以需要使用符合要求的钙钛矿材料。

涂布速度的选择:涂布速度对薄膜的质量有很大的影响,太快或太慢都可能导致涂布质量下降。因此需要通过实验确定更佳的涂布速度。

涂布厚度的控制:涂布厚度也是影响薄膜质量的重要因素。需要According to实验结果确定更佳的涂布厚度。

涂布环境的控制:钙钛矿容易与空气形成氧化,提供防氧化的涂布环境尤为重要。

烘干温度和时间的控制:烘干温度和时间会影响钙钛矿晶粒的形成和薄膜的致密程度,需要According to实验结果确定更佳的烘干条件。

操作规范:使用涂膜机操作时,需要注意操作规范,避免操作不当导致涂布质量下降或机器损坏。

数据记录和分析:对制备的薄膜进行详细的数据记录和分析,以便更好地优化制备流程和提高涂布质量。

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Advantages of drawdown blade method in preparation of perovskite solar cells

- 9Application of Film Applicator in PVDF-HFP Material Research