Summary of special test methods for Pigment

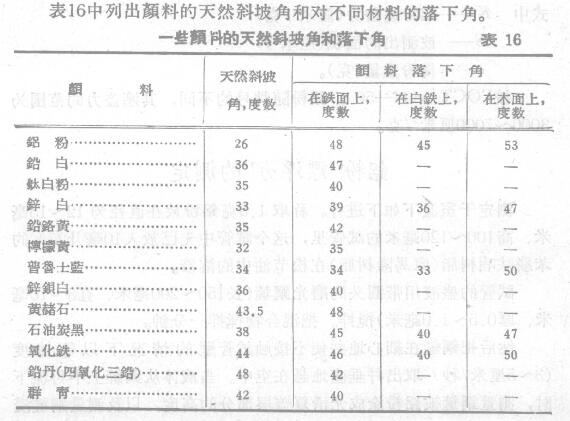

At the end of this article, it is necessary to discuss the determination of some constants that have practical significance in some special cases, for example, in the design of paint factories-about the determination of the slope angle of the natural slope when the pigment is piled up and the pigment in different conditions. Problems such as drop angles on materials. Some methods for determining these constants are described in this chapter.

Determination of natural slope angle of pigments

Determination of natural slope angle of pigments

The natural slope angle of the paint should be understood as the angle formed by the dry paint and the ground plane when the paint is freely withdrawn. This angle depends on the specific gravity, degree of dispersion and coefficient of friction of the pigment, etc. Generally speaking, the greater the degree of dispersion of the pigment, the greater the natural slope angle, but for highly dispersed pigments, this relationship is not found. (Related instrument: specific gravity cup)

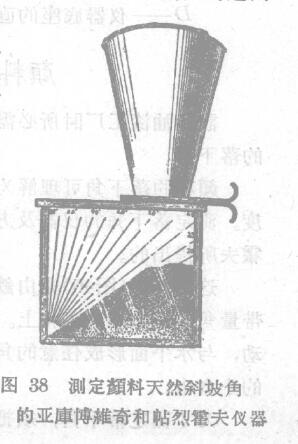

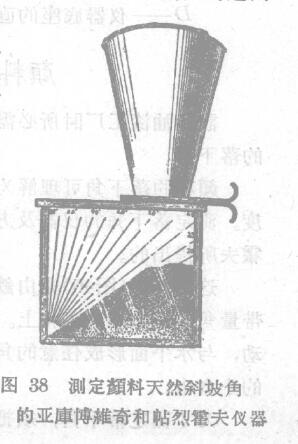

Determination of Natural Slope Angle by Yakubovich-Terehoff Method

The standard scale of the protractor (protractor) is engraved on the rear wall of the rectangular glass dish, and a white iron cover with a funnel is set on the glass dish (Figure 38). The lower hole of the funnel is covered by two gates, one of which is closed and the other has a hole with a diameter of 10 mm. After filling the funnel with dry paint, open the closed gate well and gently stir the paint with a glass rod; the paint is evenly distributed in the dish, and the well is at a certain angle to the ground plane.

The measurement is considered complete when the pigment approaches the left wall of the glass dish opposite the funnel. At this time, close the funnel with a closed door, and read the angle formed by the paint and the ground plane on the back wall of the glass vessel. This method is suitable for determining the natural Coppel angle of air-dried pigments.

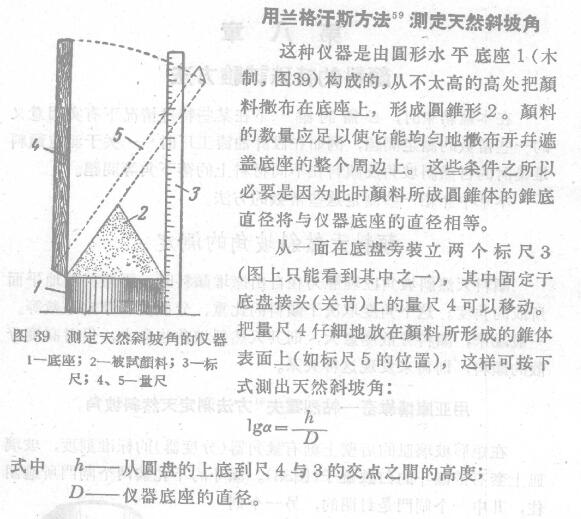

Determination of Natural Inclined Angle by Langerhans Method

Determination of drop angle of paint

One of the constants necessary when designing a paint plant is the drop angle of the paint on any kind of surface.

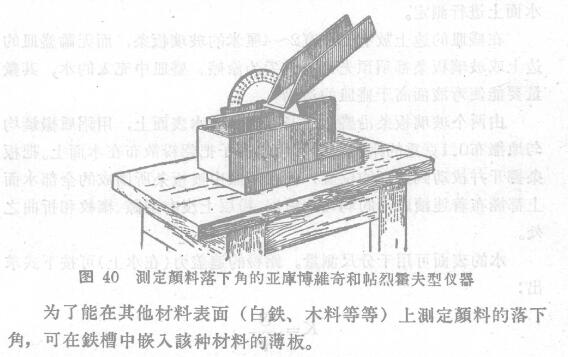

The fall angle of the paint can be understood as the angle of inclination of the surface when the paint falls freely from the surface. The instrument and method for measuring the falling angle were proposed by C..B. Yakubovich and KH. Terekhov.

This only device (Fig. 40) is a trough rolled from an iron sheet, and its bottom end is fixed on a shaft with a protractor center behind the trough. There are screws under the trough, which can be used to make the iron tank rotate around the axis and form any angle with the horizontal plane. The paint spilled from the iron trough fell into a small box at the end of the iron trough.

In order to measure the falling angle, the paint must be sprinkled on the upper end of the iron tank from the funnel installed on the upper part. At the beginning of the test, the iron bar forms the smallest angle with the horizontal plane. Then, use the screw to gradually raise the iron tank until the pigment starts to slide down freely from the iron tank surface. At this time, the angle can be seen on the protractor; this angle is also the falling angle of the paint on the iron surface.

Determination of hiding power of aluminum powder

The hiding power of the aluminum powder is measured on the surface of water in a rectangular vessel measuring 500 x 200 x 100 mm. (Related instrument: hiding power paper)

There are two glass slats with a width of 2~4 cm on the side of the container, and both the edge of the container and the broken glass slats must be properly wiped with paraffin wax in advance. Fill the container with water in such an amount that the meniscus is higher than the edge of the container.

Two glass slats are used to spread aluminum powder with a weight of 0.1 gram evenly on the water surface of Changsuo Guocheng. Then use a soft brush to spread the aluminum powder over the water. Remove the slats and move them to such a position that the entire water surface surrounded by the slats in the container is covered with a continuous piece of uniform powder layer, and there are no gaps or fine lines on the powder layer. and bends.

The surface of water can be measured with a micrometer. The hiding power (on water) of pin powder can be obtained as follows:

Determination of "Buoyancy" of Aluminum Powder

The measurement was carried out at room temperature as follows. Weigh 1.5 grams of aluminum powder and put it in a test tube with a diameter of 12-15 mm and a height of 100-120 mm. 10 ml of 25% benzofuran resin (coumarone resin) has been placed in this test tube A solution in turpentine.

The liquid in the test tube is stirred with a polished steel bowl with a round head (length 150-200 mm, width 8-10 mm, thickness 0.5-1.0 mm). Stir the mixture one part potassium. (Related instrument: Stirrer)

Then take the steel bell out at a constant velocity (3-5 cm/s) and hang it vertically in the air without touching the wall of the test tube carefully. When the liquid no longer runs off the steel bell, measure the height of the part of the steel bell coated with aluminum powder for a smooth coating, and measure the full depth of the steel bell immersed in the mixture. Measurements are made with a micrometer. The ratio of the length of the measured light treatment cover layer part to the total length of the submerged end of the steel mirror is expressed as a percentage, and the buoyancy of the 9 powder is determined according to this ratio.

The buoyancy of aluminum powder varies from 40% to 80% depending on its grade.

- 1Summary of determination methods for hiding power of coatings

- 2Pigment hiding power

- 3Determination of Coating hiding power

- 4GB/T 23981.2-2023: Paints and varnishes - Determination of hiding power - Part 2: Checkerboard method - Interpretation

- 5Concept, influencing factors and determination method of Coating hiding power

- 6Mayer Rods: The right-hand man for hiding power tests

- 7Coating performance testing: ensuring the efficiency and mass of the painting process

- 8Coating hiding power measurement

- 9Application of paint film Applicator in hiding power test

Determination of natural slope angle of pigments

Determination of natural slope angle of pigments