what is the coating Leveling and Sag resistance

Leveling and Sag resistance

Coating leveling and sag resistance are important properties of a coating that determine its performance and appearance when applied to a substrate. Here is a brief explanation of each term:

Coating Leveling: Leveling refers to a coating's ability to flow and spread evenly on a surface after being applied, resulting in a smooth and uniform finish. Good leveling helps to eliminate surface defects such as brush marks, roller marks, or orange peel effect, which can negatively impact the appearance and performance of the coating. Leveling is influenced by factors such as the coating's viscosity, surface tension, and drying time, as well as the application method and environmental conditions.

Sag Resistance: Sag resistance is the ability of a coating to resist the downward flow (sagging) or deformation under the influence of gravity after being applied to a substrate, particularly when applied in thick layers or on vertical surfaces. Sagging can lead to an uneven film thickness, drips, and an unsightly appearance. A coating with good sag resistance will maintain its intended shape and thickness during the drying and curing process. Sag resistance is influenced by factors such as the coating's viscosity, thixotropy, and film-forming components, as well as the application method and environmental conditions.

Both leveling and sag resistance are essential for achieving a high-quality, aesthetically pleasing, and durable coating. Balancing these properties can be challenging, as increasing sag resistance may negatively impact leveling and vice versa. Therefore, it's crucial to optimize the formulation and application conditions to achieve the desired balance between these two properties.

how to test

To test coating leveling and sag resistance, several test methods can be employed. Here are a few common methods:

Drawdown Test:

For this test, you'll need a drawdown applicator (such as a bar applicator), a coated panel or substrate, and a controlled environment for drying.

a. Prepare a uniform coating sample and apply it to the substrate using the drawdown applicator.

b. Allow the coating to dry in a controlled environment, as specified by the coating's technical data sheet.

c. After drying, visually inspect the coating for any surface defects or irregularities, such as brush marks, roller marks, orange peel effect, or sagging.

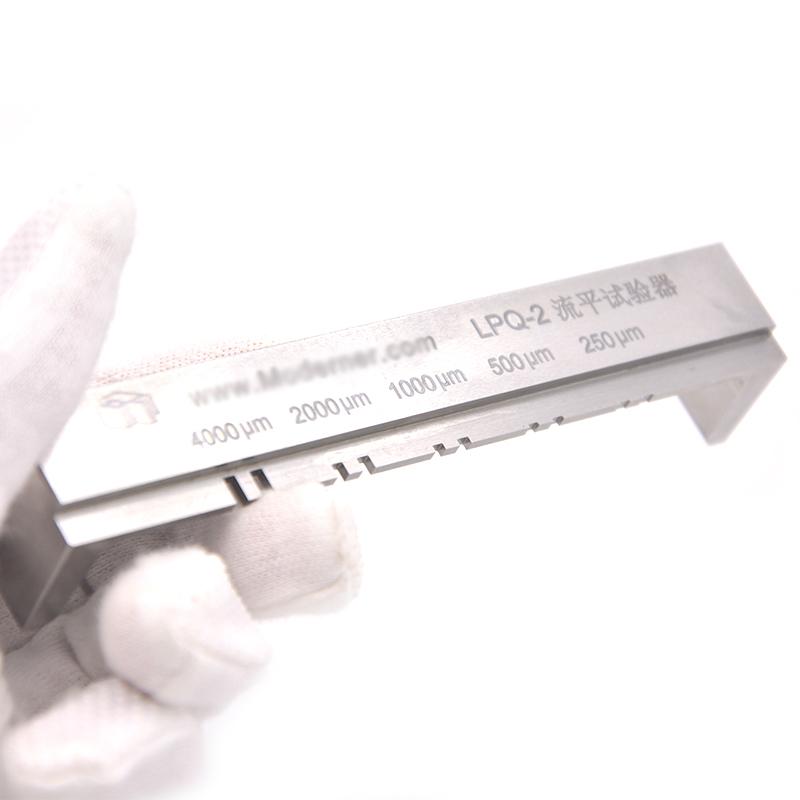

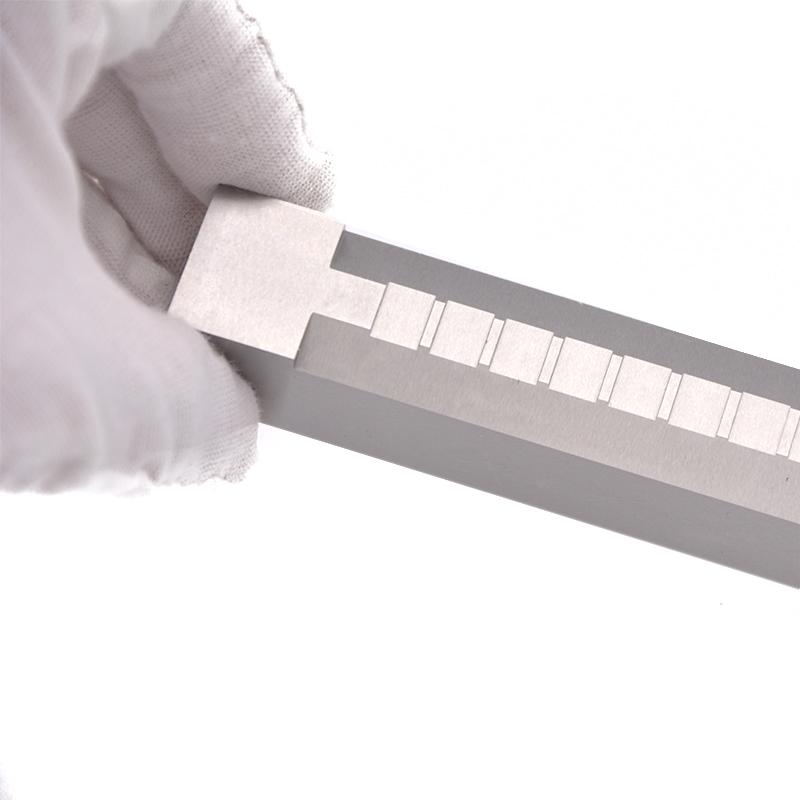

Sag and Leveling Test (Sagometer):

The sagometer is a device specifically designed to test sag resistance and leveling.

a. Prepare a uniform coating sample and apply it onto the sagometer's applicator channels, ensuring that the coating is applied in varying thicknesses.

b. Position the sagometer vertically and allow the coating to dry in a controlled environment.

c. After drying, inspect the coating to determine the maximum thickness at which the coating did not sag.

Inclined Plane Test:

This test is suitable for evaluating both leveling and sag resistance on an inclined surface.

a. Apply the coating on a flat substrate or panel, ensuring a uniform application.

b. Immediately tilt the substrate at a specified angle (usually around 45 degrees) and let the coating dry in a controlled environment.

c. After drying, visually inspect the coating for sagging, runs, or surface irregularities.

Wet Film Thickness (WFT) Test:

This test measures the coating's thickness right after application, helping to ensure the correct thickness is achieved, which can influence leveling and sag resistance.

a. Apply the coating to the substrate using the desired application method.

b. Use a wet Film Thickness Gauge to measure the coating thickness immediately after application.

c. Adjust the application method or coating formulation if the measured thickness is outside the desired range.

Remember to follow any relevant industry standards and guidelines when conducting these tests. Also, consider factors such as coating formulation, application method, and environmental conditions that can influence the test results. Consistency and repeatability are essential for accurate testing and evaluation.

- 1Waterborne architectural coatings detection method

- 2Types, applications and evaluation methods of levelling agents

- 3Working mechanism and selection considerations of anti-shrinkage agent

- 4Coating performance testing: leveling & sagging

- 5Coating surface tension and its effects

- 6Coating leveling and sagging

- 7Key Factors and Evaluation Methods of Coating Constructability

- 8Sag problems and their solutions

- 9Coating performance testing: ensuring the efficiency and mass of the painting process