How to Spreader Anode Slurry on Aluminum Foil

Applying positive electrode paste onto aluminum foil serves to create a stable, conductive, and flexible electrode structure that enables efficient current collection and transfer in lithium-ion batteries, making it a critical step in the battery manufacturing process.

Coating a positive electrode paste onto aluminum foil is a key step in the manufacturing process of lithium-ion batteries. Here's a step-by-step guide on how to coat positive electrode paste on aluminum foil:

Materials and Tools Needed:

Aluminum foil substrate

Positive electrode paste

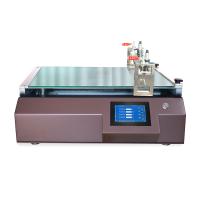

Coating equipment (e.g., drawdown blade coater, slot die coater, etc.)

Applicator blade (for drawdown blade coater)

Drying oven

Protective gloves and goggles

Step 1: Prepare the Positive Electrode Paste

Positive electrode paste is typically a mixture of active materials, conductive additives, and binders in a solvent. It is important to follow the manufacturer's instructions for preparing the positive electrode paste. Mix the paste thoroughly to ensure a homogenous and well-dispersed mixture.

Step 2: Set Up the Coating Equipment

Select the appropriate type of coating equipment for your application, such as a drawdown blade coater or a slot die coater, and set it up according to the manufacturer's instructions. Make sure the equipment is clean and in good working condition.

Step 3: Load the Aluminum Foil Substrate

Place a clean and dry aluminum foil substrate onto the coating equipment. The foil should be properly tensioned to ensure a smooth and even coating.

Step 4: Apply the Positive Electrode Paste

Using the selected coating method, apply the positive electrode paste onto the aluminum foil substrate. The thickness of the coating can be adjusted by controlling the gap or speed of the coating equipment. For a drawdown blade coater, the applicator blade can be adjusted to control the coating thickness. It's important to apply the paste evenly and smoothly to achieve a uniform coating.

Step 5: Dry the Coated Electrode

After coating the positive electrode paste onto the aluminum foil, the coated electrode needs to be dried to remove the solvent. This is typically done in a Drying Oven at a temperature and duration specified by the manufacturer's instructions. The drying process is critical as it ensures the paste is properly adhered to the foil and prevents solvent residue in the final electrode.

Step 6: Inspect and Handle the Coated Electrode

Once the coated electrode is fully dried, carefully inspect it for any defects or imperfections, such as pinholes, cracks, or uneven coating. Handle the coated electrode with clean and dry gloves to prevent contamination.

Coating positive electrode paste onto aluminum foil requires precision and attention to detail to ensure a high-quality electrode. Following the manufacturer's instructions and best practices for coating and drying is important to achieve consistent results.