Viscometer Determination Methods of Several Paints

Measuring Viscosity with a Falling Ball Viscometer

Falling ball viscometers are commonly used in the paint industry to measure the viscosity of nitrocellulose varnishes, polymerized and oxidized oils, and other viscous liquids.

The operating principle of this viscometer is as follows. If a large ball with a radius r is made of a material with a specific gravity d, it will settle into a ball with a specific gravity d under the action of gravity. In the liquid, its fall is accelerated only in the first moment. With the increase of its falling speed, the internal friction force K also increases, so that it finally reaches the moment when the internal friction force K and gravity F are balanced. From then on the take-off and landing velocity v becomes constant.

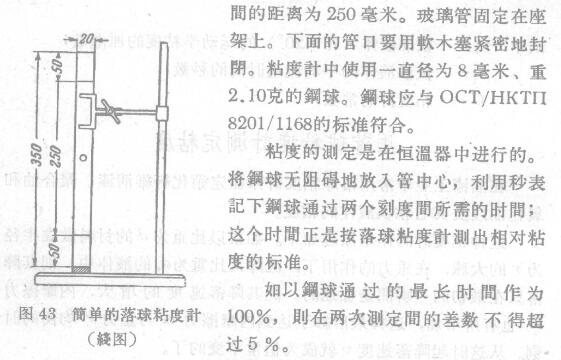

Measuring Viscosity with a Simple Falling Ball Viscometer

The simplest falling ball viscometer (Figure 43) is made of a broken glass tube 350 mm long and 20 mm in diameter. Two markings are engraved 50 mm from the nozzle

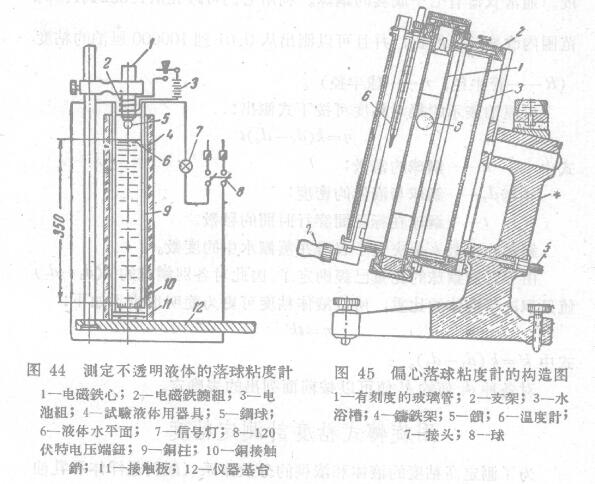

In the rubber industry, a more sophisticated falling ball viscometer (Figure 44) is used to determine the viscosity of rubber colloids. This viscometer is capable of measuring the viscosity of opaque liquids. When the steel ball falls to the bottom of the device, it presses down the contact pin located at the bottom of the device, connects the circuit of the signal light, and records the time when the steel ball falls while the light is on. The steel ball is held by the electromagnet before the test starts.

At the beginning of the measurement, the power supply to the electromagnet is cut off; the steel ball is then disengaged. Simultaneously start the stopwatch.

The instrument in which the upper ground steel ball descends along the circular axis machine is the main source of error. It is difficult to avoid the phenomenon that the steel ball descending route leaves the vertical line in practical application. This changes the gap relationship between the cylinder wall and the spherical surface, thereby affecting the time when the steel ball falls. But if take the principle that steel ball falls eccentrically in the tilted, graduated pipe then can avoid above-mentioned phenomenon to take place.

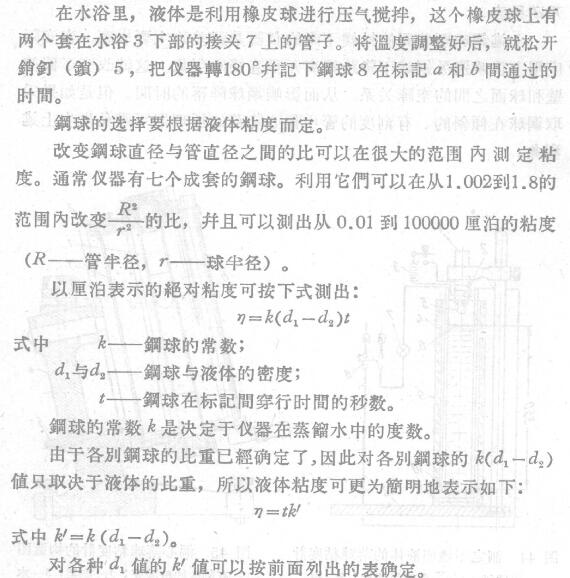

Determination of Viscosity with Eccentric Falling Ball Viscometer

The viscometer shown in Figure 45 is a glass tube 1 with a scale, the inner diameter of the tube is 16 mm, and the surface is about 20 cm; the tube 1 is installed in the Water Bath 3 by means of the bracket 2, and the whole set of equipment is at an angle of 10° to the vertical line Angle ground is installed on the iron frame 4 that is drilled closed by drill 5.

Before the test, pour the test solution (about 40 mm) into the glass tube. Borrow the control of thermometer 6 to keep certain temperature in the Water Bath. (Related instruments: constant temperature Water Tank)

Measuring Viscosity with a Rotational Viscometer

In order to measure the viscosity of high-viscosity liquids and thick dispersion systems (pigment suspensions and emulsions ), rotary viscometers with various structures are widely used.

From the point of view of rheology, the method of using an instrument with a rotating circle is a well-founded method for studying the viscosity and thixotropy of a dispersed system that has been formed. The broad flow conditions in this apparatus are consistent with simple motion.

It should be pointed out that the rotary viscometer of Mn Volarovich (Mn.Bo.aapoBHq) is very suitable for measuring the viscosity of high-viscosity pigment suspension in the paint industry.

Measuring Viscosity with PB-7 Viscometer

Made by K.

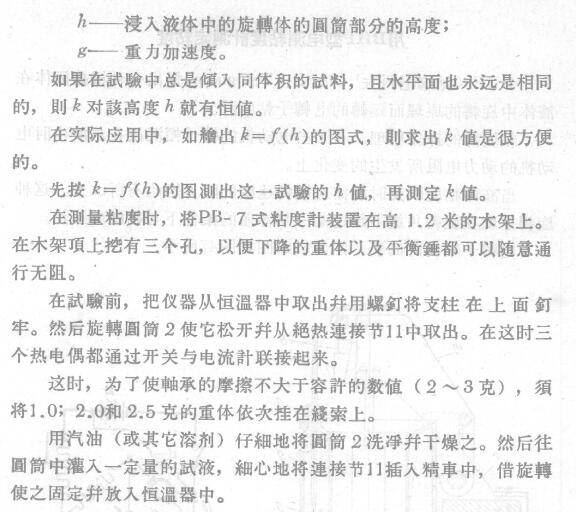

When measuring the temperature, three thermocouples 14 are used, the joints of which are installed in the sample layer through the connecting joints of the wires. The level of the sample in the empty line between the circles reaches the thermocouple above. The disc of the viscometer is placed inside the sub-thermostat, which is a brass vessel 15 with a blanket 16 set of heat. In order to maintain a constant temperature, liquid (alcohol, kerosene, oil) is poured into the container, and in order to achieve a low temperature (to -50°C, -00C), a piece of state carbon dioxide is thrown into it.

If will reach high temperature (to 100 DEG C) container 15 must assemble the firing group of the record alloy that can pass electric current. With screw 17 the thermostat is fixed on the pedestal 18 of the device.

The seat plate 13 of the viscometer is to be fixed on the support 21L by using the iron cutting joint 19 with the screw 20 on it. In order to allow the device to change hands and be taken out of the thermostat, a paper rope 23, delivered by a tackle 24, is tied to the fishing line 22, and the well is equipped with a balance clock.

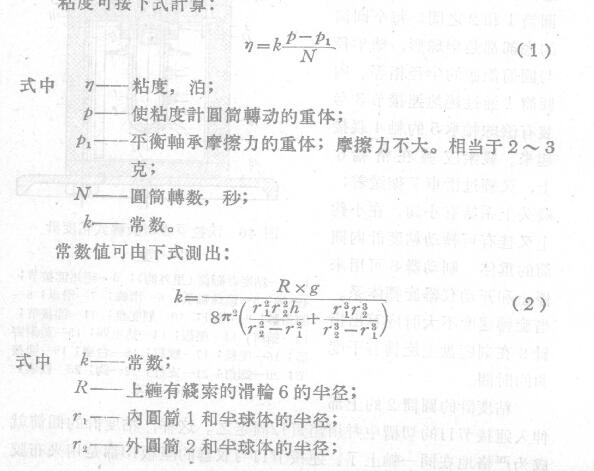

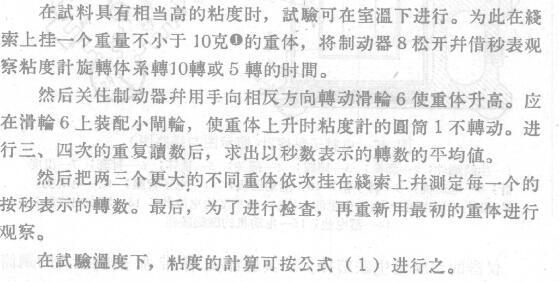

The rotary meter is a primary viscometer, that is, it can calculate the viscosity expressed in color pair units (poise) directly and without a scale.

- 1Rotational viscometer - principle, classification, application and calibrating

- 2Application of NDJ-8S digital Rotational Viscometer in viscosity measurement of cosmetic raw materials

- 3NDJ-5S digital Rotational Viscometer accurate measurement of natural oil viscosity

- 4Viscosity of polypropylene (PP) amide measured by NDJ Viscometer

- 5Application of HBDV-1H swirl/spin High Temperature Viscometer in Viscosity Determination of Plastic Particles

- 6Rotational viscometer selection guide: How to choose the right viscosity equipment for you?

- 7Principle, type and accuracy control of Rotational Viscometer

- 8Which Viscometer to Choose for Licorice Extract Viscosity Testing? How to Test?

- 9Application of Rotational viscometer in Waterborne Polyurethane Adhesive