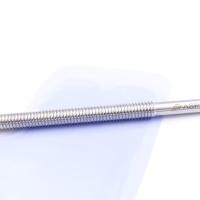

Metering rods are commonly used for applying hot melt adhesives to substrates in a variety of industrial and manufacturing applications. The hot melt adhesive is applied to the metering rod, which is then drawn across the substrate at a controlled speed and pressure to deposit a thin, uniform layer of adhesive onto the surface.

The use of metering rods for applying hot melt adhesives offers several advantages, including precise control over the thickness and coverage of the adhesive, as well as high-speed and efficient application. The thickness of the adhesive layer can be adjusted by selecting a metering rod with the appropriate groove size, or by adjusting the speed and pressure of the rod as it is drawn across the substrate.

Hot melt adhesives are commonly used in industries such as packaging, woodworking, automotive, and construction, where a strong, fast-setting adhesive is required. The use of metering rods for applying hot melt adhesives can improve production efficiency and quality control by ensuring consistent adhesive coverage and thickness, reducing waste and rework, and improving bond strength and durability.

Metering rods can be used with a variety of hot melt adhesive types, including thermoplastic and reactive adhesives. The type of adhesive used will depend on the specific application and substrate materials involved.

In the packaging industry, metering rods are commonly used for applying hot melt adhesive to cartons, boxes, and other packaging materials. The adhesive is applied to the metering rod and then drawn across the surface of the packaging material, ensuring even coverage and a strong bond between the layers.

In woodworking and furniture manufacturing, metering rods can be used for applying hot melt adhesive to edge banding, veneers, and laminates. This allows for precise control over the thickness of the adhesive layer, ensuring a strong and durable bond between the layers.

In the automotive industry, metering rods can be used for applying hot melt adhesive to interior trim components, headliners, and other interior surfaces. The precise control offered by metering rods ensures consistent adhesive coverage and thickness, resulting in strong and durable bonds.

Overall, the use of metering rods for applying hot melt adhesives offers significant benefits in terms of efficiency, consistency, and quality control. By ensuring even coverage and precise thickness, metering rods can improve production processes and help to achieve strong and durable bonds between substrate materials.

- 1Coating Metering rodsFAQ

- 2Coating Metering rod: Mayer-Rod

- 3Cleaning, maintenance and service life prediction of coated measuring rods

- 4Analysis of Advantages and Disadvantages of Mayer Wire Bar Coater

- 5Explanation of the principle and structure of the wire rod applicator

- 6How to choose these experimental coating equipment?

- 7Why are paper coaters and converters transitioning to forming metering grooves?

- 8Metering Coating Stick Notes

- 9Metering rods for production should be wound or formed?