How to ensure accurate Stormer Viscometer measurements? with calibration method

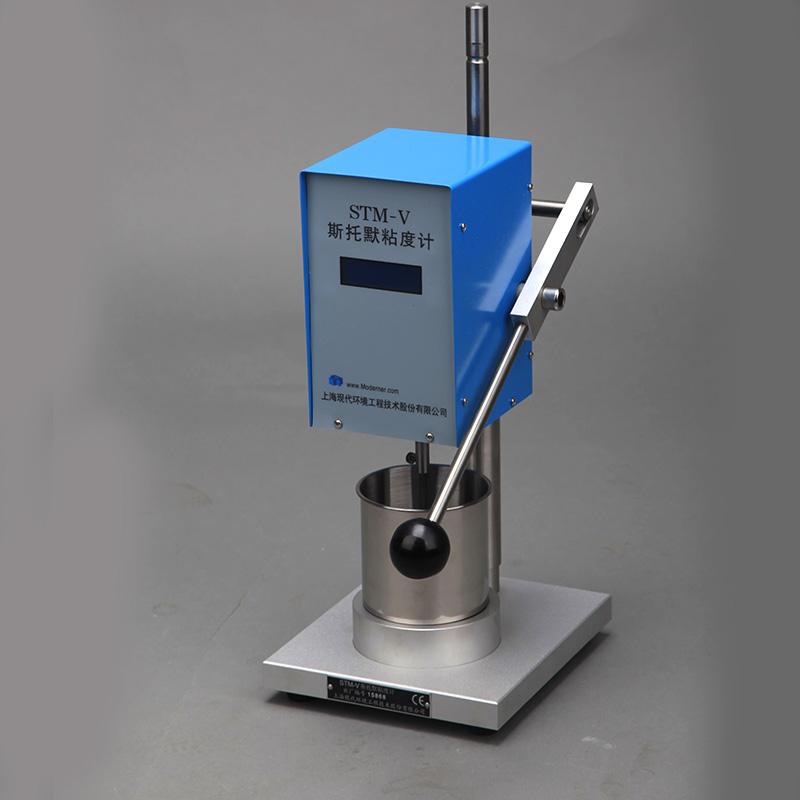

Stormer viscometers are commonly used to measure the viscosity of paints and other coatings. Over time, Stormer viscometers can become inaccurate due to factors such as wear or temperature changes.

Here are the steps you can follow to calibrate your Stormer Viscometer:

Check the manufacturer's instructions: The manufacturer's instructions will give you specific steps for calibrating your Stormer Viscometer. Follow them carefully to ensure accurate results.

Determining the Correction Factor: To calibrate your Stormer Viscometer, you will need to determine the correction factor for the specific type of paint or coating you are measuring. This can be done by comparing the Stormer readings to a reference measurement made with a more accurate instrument such as a Rotational Viscometer.

Apply Correction Factor: Once the correction factor is determined, apply it to the Stormer reading to obtain a corrected viscosity value. This can be done manually or with the help of a software program.

Repeat the process: Repeat the calibration process with a different paint or coating to ensure the accuracy of a series of measurements.

Stormer viscometers may wear out over time from use or exposure to chemicals, which can affect their accuracy. It is therefore recommended to calibrate the Stormer Viscometer regularly, for example every six months or after heavy use, to ensure accurate measurements.

- 1Viscosity of polypropylene (PP) amide measured by NDJ Viscometer

- 2Which Viscometer to Choose for Licorice Extract Viscosity Testing? How to Test?

- 3Application of Rotational Viscometer in juice viscosity test

- 4Working Principle, Classification and Application of Capillary Viscometer

- 5Principle, Characteristics and Application of Dial Viscometer

- 6Basic Principle and Application of Ceramic Viscometer

- 7Principle, Characteristics and Application of QND Viscometer

- 8Determination of epoxy resin viscosity by Rotational Viscometer

- 9Rotational viscometer selection suggestions