Application of Colorimeter in Color Determination of Cooked Oil and varnishes

1. Application of Colorimeter in color determination of cooked oil and varnish

To determine the color of oils, cooked oils, varnishes and resins, a Colorimeter can be used.

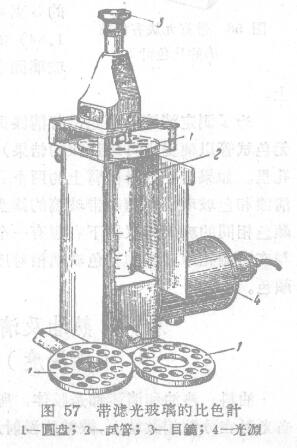

In this Colorimeter, filter glass with a certain color is used as a colorimetric standard (Fig. 57) on three discs with equidistant height devices. Color can be measured by color value. The color value is indicated by the milligrams of free iodine contained in 100 milliliters of iodine-containing potassium iodide solution of the same color as the test solution (its depth is 10 mm).

The first disc has 10 pieces of glass. The colors correspond to the colors of 1 to 9 mg iodine (one of the 10 pieces is colorless), the glass on the second disk corresponds to 10 to 90 mg iodine according to its color, and the third disk The upper glass then corresponds to from 100 to 900 mg iodine respectively. _Adding one disc to another, the colors corresponding to the iodine content in 100 ml potassium iodide solution from 1 to 999 mg can be formulated on the disc.

The varnish, oil or resin to be tested is placed in a small glass test tube (10 mm high) fitted under the disc. The rotary disc adjusts the position of the two halves of the field of view in the instrument's eyepiece to form a perfect circle of equal color intensity.

The test is carried out under artificial lighting conditions, for which a reflector with a fluorescent lamp or a reflector 2 with a blue glass filter and an ordinary lamp shall be installed on the apparatus. (Related instrument: refractometer)

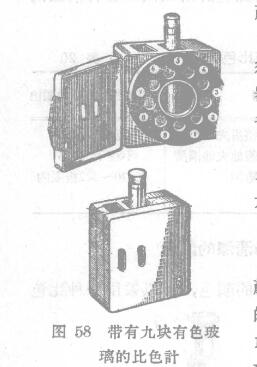

Alternatively, the color of the paint to be tested is compared with nine different colored glasses corresponding to the sulfuric acid solution of potassium diazolate25.

An overview of the instrument is shown in Figure 58.

The lightest glass matches the color of bleached linseed oil; the darkest glass matches the color of 3 grams of potassium diacid in the test tube in 100 ml (specific gravity 1.84) of sulfuric acid solution. These glasses are fixed on discs placed in a special case.

To determine the color of the varnish, pour the varnish into a test tube (the same colorless test tube must always be used for comparable results), and place the test tube in the upper right hole of the instrument. If the lacquer and colored glass in the test tube are observed under the incoming light through the two holes on the forearm of the instrument, it is possible to select a glass whose color is the same as that of the sample by rotating the disc with the glass. There is a small hole showing numbers on the lower right side of the instrument. This number corresponds exactly to the colored glass seen in the hole on the right. This number indicates the color of the varnish to be tested.

2. Quality determination of varnish transparency

The determination of the clarity of the varnishes is carried out on glass slides. Therefore, the flakes must be soaked in varnish, then taken out, and placed flat in a warm (18~20°C), dry (relative humidity 60~65%) and soil-free room. When the solvent evaporates, the film does not become oily (only a very slight turbidity). The film should be completely transparent after drying. (Related instruments: constant temperature and humidity Test Chamber)

- 1How the Colorimeter works

- 2Test method for color of adhesive resin - Platinum cobalt colorimetric method

- 3Colorimeters vs Spectrophotometers: Understanding the Differences Between Color Measurement Techniques

- 4Use of Colorimeters

- 5The principle and use of Colorimeter

- 6What is a Colorimeter? Types of Colorimeters

- 7What types of Colorimeters are there?

- 8Functional Comparison of Colorimeter and Spectrophotometer

- 9Advantages of Spectrophotometers: Why Are Colorimeters Not Enough?

-

-

-

-

-

-

HANNA HI784 Ion Meter Tintometer$ 204.00