Determination of varnish transparency (turbidity) by photoelectric Glossiness Meter

The measurement can be carried out by using a photometer (related instrument: gloss meter) connected with a mirror galvanometer (sensitivity: 1·10-9a) with Shixi photocell. The photocurrent, which varies with the turbidity of the test solution, can deflect the fingers of the galvanometer. By means of the third light source and the mirror of the galvanometer reflecting this deflection, the enlarged deflection angle can be obtained on the scale.

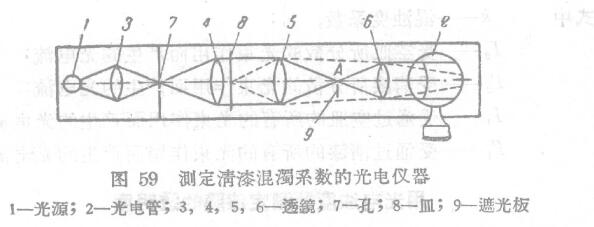

A sketch of the instrument is shown in Figure 59. The instrument is a wooden box with a light source 1

(50 watt car lights) with selenium photocells 2 and lenses 3,4,5,6.

The lens 3 guides light from the light source into a small hole 7 in the inner wall of the box. This hole 7 is located at the main focus of the lens 4 . Thus, a bundle of parallel rays emerges from the lens 4 . On the optical path of this Dongguang, a dish 8 is inserted, and the lacquer to be tested is filled with a thickness of 10 mm in the dish 8. The parallel light beam impinging on lens 5 is concentrated on its main focus (point A), after which the light is slowed down to lens 6 and at the same time, the lens changes the light beam from scattered beam to parallel beam again.

Only part of the light passes through the varnish in the form of parallel beams. Another part of the incoming light is scattered due to the turbidity of the varnish. The route of the light divided by the varnish layer through the lens group is shown in the virtual machine on the figure. The small selection plate 9 made of opaque material moves on a plane perpendicular to the axis of the lens group (this plane intersects with the axis center of the lens group and point A), so that it can move on the designated plane And arbitrarily let go or choose to hold light, such light passes through the varnish in the dish 8 and gathers at the point A place without deflection.

At the shading plate shown in the figure, the light gathered to point A can pass through the well unimpeded and hit the photocell; if the shading plate is placed on point A, these rays will be completely cut off. (Related instrument: light transmittance meter)

The rays dispersed by the varnish and passing between the lenses 5 and 6 with a wide beam are attenuated to a certain extent by the visor 9.

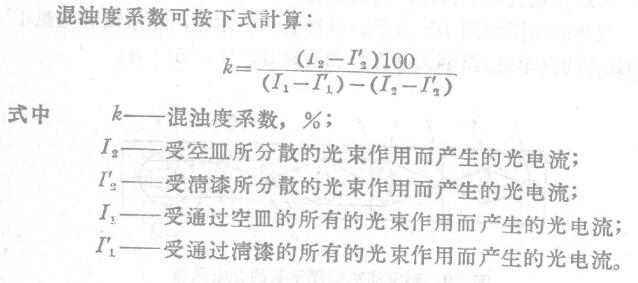

In order to determine the coefficient of oil mixing degree, under the condition that the shading plate does not block the direct light, the current I i passing through the photocell should be measured first . The current I2 through the photocell is then measured when the selector panel is covered . These measurements are made with empty pans and pans filled with the varnish to be tested.

-

-

-

-

JND WGG60-EJ metal Glossiness Meter$ 353.00

-

-

-

-

- 1Opacity and Transparency Test Methods

- 2The difference between photometers at different angles

- 3Difference Between Colorimeter and Spectrophotometer

- 4Varnish, Clear Oil and diluting Agent Appearance and Transparency Determination

- 5Spectrophotometer FAQ and Processing

- 6Spectrophotometer instrument use and maintenance

- 7Spectrophotometer classification and principle introduction

- 8Introduction of Determination Method of Achromatic Color

- 9Atomic Absorption Spectrophotometer (Model 310) Operation Instructions

-

-

-

YUEFENG FP6427 Flame photometer Na/Li$ 1450.00

-

YUEFENG FP6426 Flame photometer K/Ba$ 1450.00

-

YUEFENG FP6422 Flame photometer Li/Ba$ 1450.00

-