Measuring the grinding degree of Paints with a micrometer

CB Yakubovich and BC Stoshoff will use a common gauge to measure the degree of grinding. According to this method, place a drop of paint paste directly between the two measuring surfaces of the gauge.

The pigment slurry sandwiched between the measuring surfaces and the unground individual pigment granules are evenly distributed on the measuring surface when the measuring gauge is screw-cut, and the excess paint flows outside. There are binders in the paint and it does not affect the accuracy of the measurement. Experiments with cooked oils and oils have proved that micrometers can never determine the thickness of the oil layer under these conditions. (Related instrument: Coating Thickness Gauge)

The assumption that individual pigment particles may break up under the pressure of the gauge has not been confirmed, although specialized studies have been carried out.

The data obtained from the research work show that the various paints have the best properties when the degree of grinding of the pigment particle size is about 5µ. However, due to the different types of sub-pigments, the performance of the paint is still good when the particle size is 10~30µ.

According to OCT 10086-39 test method 9, use a broken glass rod to spread a drop of color paint evenly on the surface of the smooth micrometer screw. The center of the tested color paint is between the measuring surfaces. When the ratchet wheel crosses 2~3 windows, the movement of the ratchet stops, and the rotation of the drum also stops immediately. The thickness of the paint layer. The drum wheel is deflected 0.5 degrees from the card view, and the paint layer thickness is equivalent to five thousandths of a millimeter or five microns.

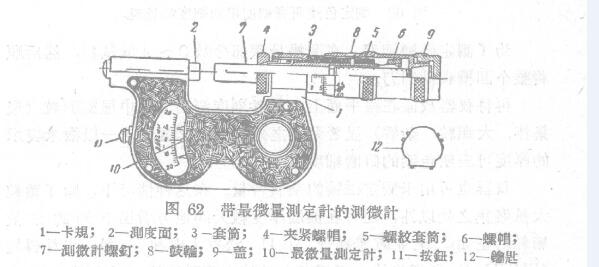

In order to more accurately determine the degree of grinding, as well as those paints whose grinding degree can be measured instinctively with ordinary micrometers, you can use the micrometer with the most micrometer (MHHHMETP) (Figure 62), which measures The accuracy of measuring the degree of grinding can reach 0.002 mm. (Related instruments: grinding machine)

In addition to the above-mentioned quantitative determination methods, there are also some methods of qualitatively measuring the degree of color and lacquer research by using a special standard 5; this standard is made by adding different fineness of jade and emery powder to the lacquer. One of the methods using this standard was developed by CB Yaku Bović and 6.C. Stokoff.

The data on the grinding degree of the prepared paints are listed in the relevant technical conditions and Timing 3°.

- 1Three differences between Disperser and Grinder

- 2What is the working principle of the dispersion grinding machine?

- 3What is the difference between stirring, dispersing and grinding?

- 4Grinding and dispersing techniques

- 5What is the effect of pigment dispersion and its impact on pigments? What are the detection methods?

- 6What kind of grinding paste is the three-roll Grinder suitable for?

- 7Why can't the standard formula for paint production be directly formulated into abrasive paint slurry?

- 8What are the commonly used main equipment for emulsion paint production?

- 9Production technology of styrene-acrylic interior wall engineering paint