Coating platings Thickness Gauge FAQ and its solution

The coating Thickness Gauge is an instrument used to measure the thickness of the coating or coating on the surface of metal, ceramics, glass and other materials. The coating Thickness Gauge is also a kind of Film Thickness Gauge, which can help users evaluate and control the quality and thickness of the coated object.

common problem

Measurements are inaccurate.

Instrument readings are unstable.

The instrument is malfunctioning.

Solution

Handling of inaccurate measurement results: check the calibration and calibration of the instrument, whether recalibration or calibration is required; check the preparation of the sample surface, such as whether there are oxides or impurities; check whether the probe and measurement method of the instrument are correct, and choose the appropriate one Probe and measurement method; ensure that the temperature and humidity conditions of the instrument meet the requirements.

Handling of unstable instrument readings: Check the environmental conditions of the instrument readings, such as whether there is an interference source, whether there is a radiation source, etc., and keep it away from the interference source; check whether the instrument probe and measurement method are correct, and adjust the probe and measurement method to improve measurement accuracy Check the power supply of the instrument to ensure that the power supply is stable.

Troubleshooting of the instrument: Check whether the instrument is damaged in appearance or parts, such as whether there is a loose connector or a damaged probe; check the power supply of the instrument to see if there is a power problem; For repairs, contact professionals in time.

Precautions

In addition to the above handling methods, the following points should also be noted:

Before using the coating Thickness Gauge, read the operation manual carefully to understand the use method and precautions of the instrument.

During the measurement, it should be ensured that the preparation of the sample surface meets the requirements to avoid affecting the measurement accuracy.

Calibrate and calibrate the coating Thickness Gauge on a regular basis to ensure the accuracy of the measurement results.

Keep the instrument clean and maintained, and avoid dust or dirt from affecting the instrument.

Pay attention to safety when using the coating Thickness Gauge to ensure the personal safety of the operator.

In short, the coating Thickness Gauge is a commonly used testing instrument, and it needs to be maintained and calibrated during use to avoid failure and inaccurate measurement results. At the same time, it should be used according to the operation manual and precautions of the instrument to ensure safe and reliable operation.

- 1General guidelines for the use of platings

- 2Simple Selection Method of Magnetic Induction Coating Thickness Gauge

- 3Tide Review: McCourt Coating Thickness Gauge MikroTest G 6

- 4Yuwen Automobile Coating Thickness Gauge Function Video Introduction

- 5Yuwen EC-777 Automobile Coating Thickness Gauge Beauty Appreciation

- 6QNIX Nix 4200 Magnetic Induction Coating Thickness Gauge Real Photo Appreciation

- 7QNIX 8500 Coating Thickness Gauge Real Photo Appreciation

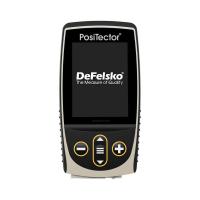

- 8Defelsko Positector 6000 NRS1 Coating Thickness Gauge Beauty Appreciation

- 9Defelsko PosiTest mechanical coating Thickness Gauge evaluation [with high definition real picture]