Treatment method of surface before painting

In order to test the properties of varnishes and enamel on the surface finishing, "leveling", sanding "reflection", etc., wood and iron boards (dimensions 200 x 400 mm) pre-treated in an appropriate way shall be used. (Related instrument: leveling meter)

The treatment must be carried out according to the following steps, that is, the surface is clean, primed and puttyed.

To make the surface clean, the oxide skin on the unpainted iron surface should first be sanded with a diamond block. Remove it with a sander, and then use H oil or lacquer oil (pine perfume) to wash off all grease. Finally, dry it with a dry The surface of the unpainted dry wood is sanded with No. 1 sandpaper, and the joints are coated with an alcohol-soluble varnish. This is fixed to prevent these joints from showing through under the paint film in the future.

The painted iron surface should first touch or burn off the old paint film. When touching the old paint film on the surface of the lacquer board, you can use a brush to brush with 10% paraben solution. When it changes under the action, use a scraper to remove the paint film, then wash the machine with clean water until it shows a neutral reaction, and then dry it with a cloth. In order to remove the old paint film, in addition to using mechanical fluid, it is also You can use a standard cleaning agent mixed with various organic agents, and paint coal can also be removed by spraying fire. After the film is removed, clean and scrub the surface.

It is also possible to utilize atomic finished products produced by the oil speed factory. The first layer of putty should be left for 2 to 1 hour, then apply and cut the second layer, and then scrape the third layer after 2 to 3 hours. (Related equipment: applicator)

After 14-16 hours of uncoated putty, use a water-free pumice stone to move evenly on the putty-coated board surface to smooth the surface, so that all uneven places on the putty layer can be polished smooth, and the polished surface needs to be polished. It is completely smooth. After grinding, use a cloth to clean the surface of the board. If the surface of the putty is accidentally damaged, it can be repaired with glue putty. The glue putty contains 5% master painting glue, 70% Baisheng, 20 % water, and 5% oil (approximate figure), after the surface is dry (after half an hour to 1 hour), sand the surface with No. 0 sandpaper to make the surface clean and float. Again, just make the surface clean on a dry surface, brush clean with a dry brush on the sanded surface, and then paint. (Related instrument: drying time Tester)

Use a No. 20 or No. 12 plain brush to apply the paint on the clean surface. The brush marks left after the paint removal can be eliminated with a flat brush. Move in a direction perpendicular to the brush marks on the surface to remove the paint. Use a flat brush; there should be no visible brush fatigue on the surface after brushing. Use an oil-based base paint when removing a finished surface.

When the paint is dry (after 48 hours), remove the second coat of oil-based paint and sand it with pumice powder and water until the entire surface becomes a uniform matte surface, and the surface treatment is over. (Related instrument: gloss meter)

The time required for surface treatment can be significantly shortened if fast materials (nitrification primer and nitrate base paint) are used. According to the regulations of OCT10086-39, the surface treatment process can be simplified to only two coats. One layer of oil-based paint (M, government M, zinc white), the drying time of each layer is 2 days and nights at 20°C, after drying, sand with pumice stone and water, on the watch treated by any method , can measure a series of properties of varnishes and enamel, such as the de-decoration performance and leveling performance on the surface, etc., after each debrush, the first coat of varnish should be polished and smoothed before it becomes enamel. For sanding properties, a new treatment with oil-based paint is required each time. The test for sanding properties must only be carried out when the treatment is done with wood dust.

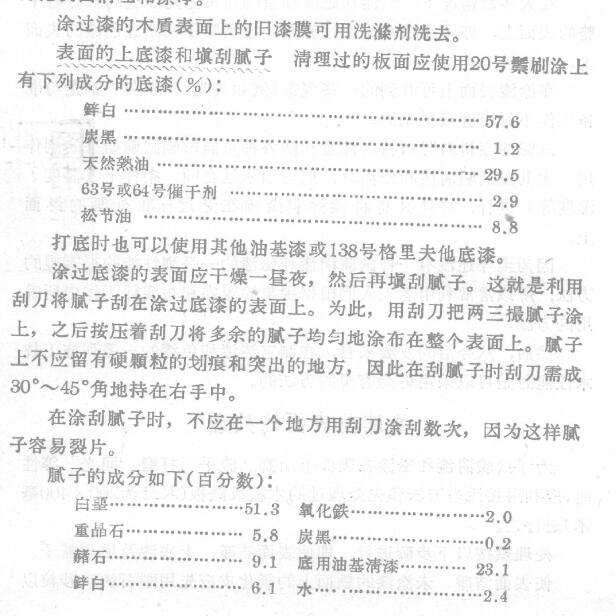

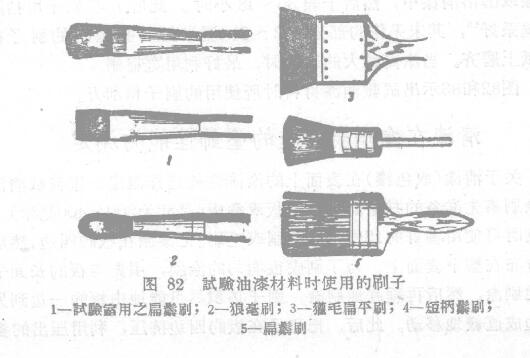

The scrapers and brushes used for scraping and removing thin boards need to be properly treated. Wooden scrapers should be polished with No. 3 sandpaper when buried, then cleaned with cooked oil, and then wiped clean with a cloth; metal scrapers should be No. 3 Sanding; No. 12 and No. 20 professional brushes and brushes should be pre-dipped in oil-based varnish or solvent-based varnish, and then allowed to dry for 36-48 hours. The part is 2 ~ 2.4 cm long, and the tied brush is smoothed on the sandpaper. When painting larger surfaces, it is recommended to use a wide brush. Figures 82 and 83 show the brush and scraper used when testing the paint material.

- 1LPQ Leveling Tester, Leveling Tester Instructions for Use

- 2Film sag

- 3Film levelling

- 4Function and application of curing agent

- 5Problems in forming smooth films: levelling, retraction, shrinkage

郑顺兴 - 《涂料与涂装科学技术基础》

- 6Pigment specific gravity measurement method

- 7Characteristics of drying performance of polyurethane paint for wood

- 8The drying characteristics of nitro paint

- 9Coating leveling and sagging performance testing