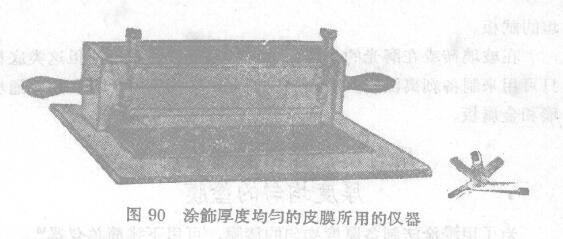

A film of uniform thickness prepared with drawdown blades

Use a scraper to prepare a coating film of uniform thickness. Generally, a straight steel rod is used as a force sheet, and the test plate is placed under it. Pour the paint into the space between the blade and the back wall of the instrument, the distance between the blade and the test plate can be adjusted with a micrometer screw, after that, move the test plate (National 90) under the blade Dry it on a very flat horizontal surface (relevant equipment: oven). In order to control the thickness of the paint layer, you can also use a steel Thickness Gauge (pot plate with a scale), and you can also use a set of joints with scientific interface. It is a steel rod with a certain gap between the press piece and the rod end.

Depending on the size of the gap beside the knife, paint films of various thicknesses can be prepared.

Depending on the size of the gap beside the knife, paint films of various thicknesses can be prepared.

It is also possible to use a variety of wire tubes of different diameters that are cut at the bottom. The height of the cut can control the thickness of the removed layer. The paint is poured into the tube and the color depth is wiped on the surface due to the movement of the tube. the direction opposite to the device. The width of the coating is approximately the same as the diameter of the tube.

The HHHJIK instrument used to make each coating film with uniform thickness is composed of a steel knife 1 ( FIG. 91 ) fixed on a support 3 by a nut 2 . This bracket can keep the knife edge and the surface of the painted test panel at a certain distance, and the knife slit 4 in the knife can adjust the distance between the knife edge and the bottom surface, and this distance can be increased from 0 to 3 mm according to the required paint film thickness. (Related Instruments: Thickness Gauge)

In order to paint a paint film, put a weighed amount of varnish or color paint on one end of the surface (bottom surface), and then move the instrument to distribute the color paint into a uniform layer. The varnish or color paint passes through the gap of the instrument gap, and leave a uniform paint layer on the bottom surface, the thickness of this paint layer is equal to the thickness of the gap in the instrument, and the thickness of the gap can be adjusted on the steel plate with scale.

The knife coating method is applicable to any type of paint material. It should be pointed out that the uniformity of the paint film thickness on all surfaces mainly depends on the smoothness of the test panel used. Therefore, when using the knife coating method, it is the same as using other In the same way as the removal method, a test panel with a flat surface is required.

Better results can be obtained with glass bricks on polished metal plates, but this type of base can only be used to make brake-off paint films. When testing paint films on painted surfaces, free glass and metal plates can be used.

- 1Why does the appearance of the paint film wrinkle, bleed and change color?

- 2Performance Test and Characterization of Polyacrylate Mixed Suspension

杨庆臣 - 《北京化工大学》

- 3How to choose these experimental coating equipment?

- 4How to control the temperature of Spreader solution?

- 5Determination of film drying performance

黄秉升 - 《《涂装与电镀》编辑部》

- 6What is the main role of talc in coating powder?

- 7Film Film thickness measurement

- 8Coating Film thickness

- 9Motorcycle film mass inspection?