Key performance and specific detection methods of resilience Coatings

Elastomeric coating is a kind of coating with high elasticity and strong flexibility. Its main components are polymer resin, filler, solvent, etc. It has good waterproof, durability, anti-ultraviolet and other properties. Elastomeric coatings are suitable for roofs, walls, and floors of various buildings. They can effectively prevent water leakage, cracks, etc., and can also play a role in heat insulation and noise reduction. They are widely used in residential buildings, industrial facilities, and public buildings.

Testing instruments and equipment

| Performance name | Equipment used |

|---|---|

| film thickness | Coating Thickness Gauge |

| Adhesion | Adhesion Tester |

| Water resistance | Water cycle Test Chamber |

| Weather resistance | Light aging Test Chamber |

| wear resistance | Abrasion testing machine |

| Bending properties | Bending test machine |

| elongation at break | Elongation at break testing machine |

Detection method

The following are the corresponding detection steps:

Film thickness:

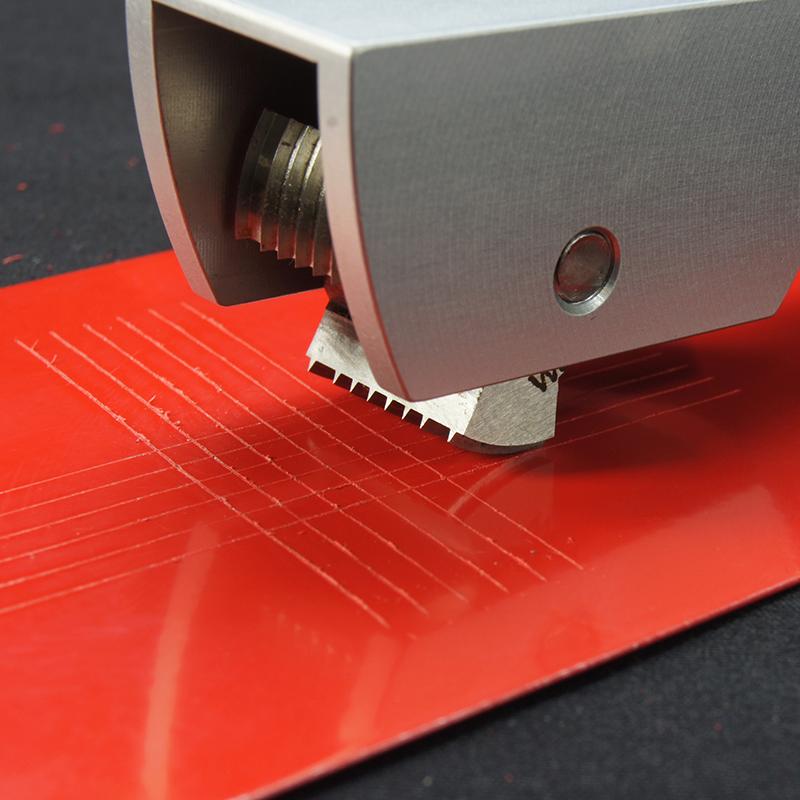

scratch a straight line on the coating surface;

The film thickness of the coating was measured using a Film Thickness Gauge.

Adhesion:

scratch a straight line on the coating surface;

Use an adhesion Tester to measure the adhesion of the coated surface.

Water resistance:

scratch a straight line on the coating surface;

Place the coating sample in the water circulation test box to carry out the water circulation test;

Observe the changes in the coating sample, such as peeling off, discoloration, etc.

Weather resistance:

Place the coating sample in the light aging test box to carry out the light aging test;

Observe the changes in the coating sample, such as color changes, surface cracks, etc.

Wear resistance:

Place the coated sample in the abrasion Tester;

A wear test was performed to observe the wear of the coated samples.

Bending properties:

Place the coated sample in the bend Tester;

Bend tests were performed to observe the deformation of the coated samples.

Elongation at break:

Coated samples were tested using an elongation at break Tester;

The elongation at break of the coated samples under tension was measured.

For each test, the specific steps will be different, and you need to refer to the corresponding test standards or methods. Commonly used standards or methods include: ASTM, ISO, GB/T, etc. During the detection process, attention should be paid to the accuracy and repeatability of the instrument, as well as the source and storage method of the sample.

- 1Two Methods and Instruments of Film Flexibility Test

- 2Key performance of powder coatings and their testing instruments

- 3How are architectural coatings flexibility tested?

- 4ASTM D5019 Single-layer roofing film reinforced CSM board (chlorosulfonated polyethylene (PE)) standard interpretation

- 5Analysis of Conical Mandrel Test of ASTM D522 Film

- 6Three methods for determining the flexibility of putty coatings

- 7Low/high Temperature Test Chamber for high-low temperature resistance test of foam materials

- 8Purpose, characteristics, operation steps and precautions of cone bending testing machine

- 9Definition and Applicable Criteria for Film Flexibility