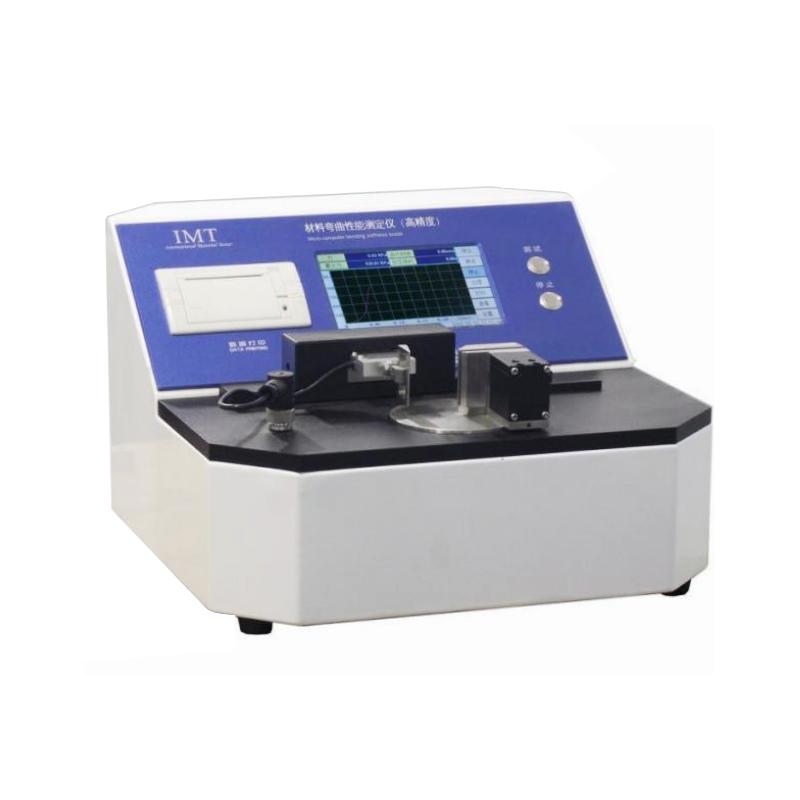

Application case of Bending Stiffness Tester in composite

The Bending Stiffness Tester can be used to measure the bending stiffness and strength of composite materials in composite material applications. Composite material is a commonly used material, which is composed of a variety of materials and has the characteristics of light weight, high strength, and high stiffness. It is widely used in aerospace, automotive, construction, and electronics. Its indicators such as bending stiffness and strength have an important influence on the design and application of composite materials, so Bending Stiffness Testers can be used to evaluate the quality and characteristics of composite materials.

Specifically, the Bending Stiffness Tester can be used to measure the deflection and mechanical properties of composite materials under bending loads, so as to evaluate their bending stiffness and strength properties. Through the Bending Stiffness Tester, the deflection and mechanical properties of composite materials under different bending loads can be measured, and compared and evaluated according to the test results.

In the design and application of composite materials, the Bending Stiffness Tester is a very important tool, which can provide strong support for the selection, design and performance evaluation of composite materials. Through the Bending Stiffness Tester, the bending stiffness and strength of composite materials can be tested, so as to evaluate its quality and characteristics, and adjust and optimize according to actual needs.

Applications

The following is a practical example of using a flexural stiffness Tester in a composite application:

An automobile manufacturing company needs to produce a body part that uses composite materials, including composite panels. In order to ensure the quality and performance of the composite material sheets, they use a Bending Stiffness Tester to test the samples, and carry out quality control and quality inspection according to the test results.

During the test, they first prepared a sample of the composite material plate, placed it on the test bench of the Bending Stiffness Tester, and performed the measurement operation according to the operating instructions of the instrument. During the test, they tested the samples with different bending loads and measured the deflection and mechanical properties of the samples. After the test is completed, they analyze and evaluate according to the test results, and make adjustments and optimizations according to actual needs.

Through the test of the Bending Stiffness Tester, they successfully evaluated the bending stiffness and strength of the composite material sheet, so as to select the composite material sheet suitable for production needs and ensure its stability and reliability during production and processing. For example, they may test indicators such as deflection and mechanical properties of composite sheets under different bending loads, and compare and evaluate based on the test results. If a batch of composite panels is found to have insufficient bending stiffness and strength, they can make adjustments to the production process to ensure that composite products are produced to meet specifications.

In short, the Bending Stiffness Tester is a very important tool in the application of composite materials, which can be used to evaluate the bending stiffness and strength of composite materials, and to carry out quality control and quality inspection. Through the test of the Bending Stiffness Tester, the composite material suitable for production needs can be selected, and its stability and reliability during production and processing can be ensured.