Coating Thickness Gauge usage and operation steps

Coating Thickness Gauge, also called cladding Thickness Gauge, is a special instrument used to measure the coating thickness of metal substrates. Since there are many brands of coating Thickness Gauges, their operation methods will also be different. But all in all, the operation steps of the coating Thickness Gauge are similar. Today, the author mainly uses the operation steps of a TIME2500 coating Thickness Gauge from Beijing Times, a familiar manufacturer of domestic Thickness Gauges, to explain how to operate the coating Thickness Gauge correctly.

The use method and operation steps of the coating Thickness Gauge are as follows:

Step 1: Prepare the object to be tested

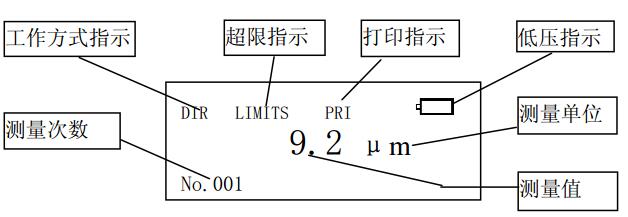

Step 2: Put the probe of the coating Thickness Gauge in the air (open space), and press the "On/C" button on the Thickness Gauge button at the same time, the instrument will display: TIME 2500 coating Thickness Gauge version 1.0 AG0500000000 information;

Note: If there is an automatic shutdown, it means that the voltage of the coating Thickness Gauge is very low. It should be understood that when the battery is replaced, it will automatically enter the measurement display interface under normal circumstances, and the screen of the Thickness Gauge will display the measured value before shutdown. If it is necessary to calibrate the Thickness Gauge, it can be calibrated by using the calibration standard at the time of purchase. The calibration method will be discussed later.

Step 3: Touch the probe of the coating Thickness Gauge vertically to the coating of the measurement file. When a beep is heard, the screen will display the measured coating thickness value. Lift the probe again and move to another position to quickly perform the second test. measurements.

Note: If a measured value is found to be different from other sets of data due to operational problems during measurement, the suspicious value can be deleted in the function selection.

Step 4: After the measurement is completed, press the "On/C" button to turn off the power.

The above are the detailed steps of using the coating Thickness Gauge. The current Thickness Gauge has been made very in line with the user experience. For example, the TIME2500 coating Thickness Gauge has single and continuous measurement modes. The probe can be moved without lifting the probe, and the display shows the measurement results instantly. Of course, these two measurement methods need to be manually set on the screen. I won't say much here.

-

-

DONGRU DR120 Coating Thickness Gauge$ 168.00

-

DONGRU DR130 Coating Thickness Gauge$ 184.00

-

-

-

-

- 1Nondestructive measurement Coating thickness

- 2Principle, application and selection of traffic coatings Coating Thickness Gauge

- 3Principle, Application and Selection of Eddy current Coating Thickness Gauge

- 4Principle, Application and Type Selection of Electronic Coating Thickness Gauge

- 5Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- 6Principle, Application and Type Selection Analysis of Chrome Coating Thickness Gauge

- 7Principle, Application and Selection of Coating Thickness Gauge for inner wall of small pipe

- 8Basic principle and application scenario of steel Coating Thickness Gauge

- 9Principle and Application Analysis of Coating Thickness Gauge