Film thickness determination by magnetic method

Magnetic measurements are capable of determining the thickness of paint-based films on any ferromagnetic metal object without compromising the integrity of the paint film. As Janus pointed out, the magnetic measurement method can be divided into the measurement method and the induction method. In the case of the measurement method, the judgment of the thickness of the non-magnetic coating film on the bottom surface of the magnet depends on the attraction of the Tester close to the bottom surface. The magnitude of the force on the bottom surface, this test number is permanent magnetism or electromagnetic iron, this force is caused by the interaction between the Tester and the magnetic charge on the bottom surface (object surface) of the Tester.

When using an induction Thickness Gauge, the thickness of the non-magnetic paint can be judged according to how it affects the induction flow in the Tester. This effect can be determined by various methods (impact method and others, etc.) . According to the data given by Thynus, the sensitivity of the determination of the number on the instrument of induction is generally lower than that of the measuring instrument.

When using an induction Thickness Gauge, the thickness of the non-magnetic paint can be judged according to how it affects the induction flow in the Tester. This effect can be determined by various methods (impact method and others, etc.) . According to the data given by Thynus, the sensitivity of the determination of the number on the instrument of induction is generally lower than that of the measuring instrument.

In the specialized literature there are described schematic diagrams of various magnetic and electromagnetic sensors which can be used to determine the thickness of non-metallic coatings on magnetic ferrous metal plates.

A brief description of several Soviet-made instruments available for the paint industry is given below.

Determination of Coating Film Thickness Using Noskov Measure Magnetic Thickness Gauge

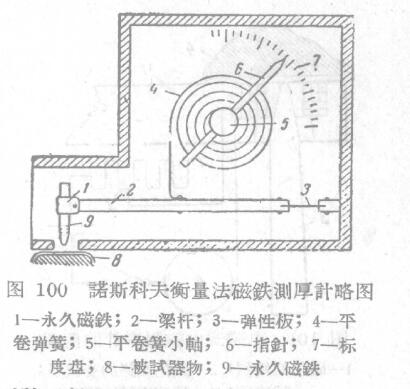

A Norskov gauge magnetic Thickness Gauge is shown in Figure 100.

Install the permanent magnet 1 on the simple balance beam 2; the balance beam is connected with the closing wall and the flat coil spring 4 through the elastic plate 3, and the other end of the elastic spring 4 is connected with the small shaft 5, and the small shaft leans against the side wall of the basin on the bearing. Rotating this small shaft can change the straight stress sent to the beam by the spring, the rotation of the small shaft can be shown by the position of the pointer 6 on the scale 7, and the measured place on the test plate 8 is close to the box. On the hole, reverse the small shaft 5 so that the magnet iron and the test plate touch each other. Then make the small shaft rotate slowly in the forward direction until the magnet iron leaves the test plate.

At the moment when the magnet iron and the test plate are separated, the position of the finger 6 on the dial 7 can be used as an indicator of the thickness of the non-magnetic paint layer on the tested part of the test plate. The instrument can be adjusted to the desired thickness range through proper selection of magnets and ferrites. It is more suitable to choose magnets with high hardness-iron-molybdenum-aluminum. It is recommended to use soft iron joints.

This joint can be fixed to the magnet with a thin sleeve made of non-magnetic material. The longer the joint, the more sensitive the gage is to smaller thicknesses.

Determination of coating film thickness with electromagnetic Thickness Gauge

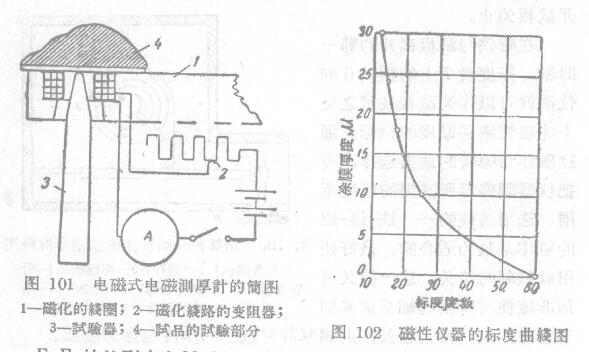

Electromagnetic iron is used instead of permanent magnetic iron in the electromagnetic Thickness Gauge. The road diagram of a simple electromagnetic Thickness Gauge is shown in Figure 101,

A magnetized coil 1 is embedded on one side of the wooden table, and a circuit (with a rheostat 2 and an ammeter on the circuit) is connected to the coil 1 by a DC power supply. The Tester 3 is a board (length 20 to 100 mm in width and 3 to 15 mm in width), one end of the pole of the Tester is cut into a wedge-shaped well so that it protrudes slightly.

In order to measure the thickness of the coating film, the sample 4 should be placed on the table, so that the tested part is on the hole of the magnetization heavy ring, and then, with the help of the rheostat, the magnetization current is connected to make the current tension reach a certain value. After that, put the Tester against the test object with its throwing end, so that due to the magnetic attraction, the Tester is fixed. After that, with the aid of the rheostat, gradually reduce the intensity of the magnetizing current until Until the Tester and the sample are separated, when the Tester starts to separate, the magnetizing current intensity can be used as a scale for the thickness of the coating film.

Since the indication of the magnetic instrument depends on the magnetism of the bottom surface of the painted film, it is necessary to calibrate the instrument once for each bottom surface material.

Figure 102 shows an approximate Graduation curve for a magnetic only device designed by MM Zhuskov for soft iron substrates.

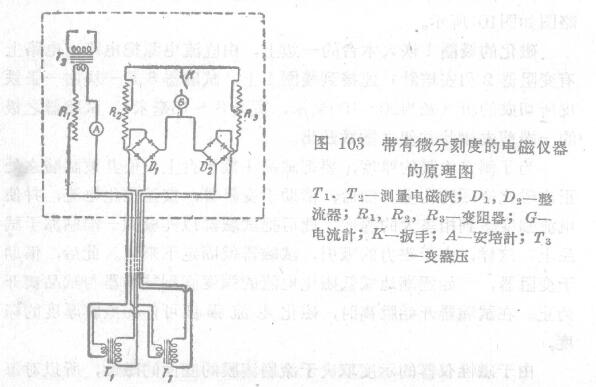

Lazarev and M Noskov pointed out that when using the electromagnetic method, the scale of the instrument should be suitable for a fairly wide magnetic range of the bottom surface. Instruments with a differential scale give better results (Fig. 103).

- 1Principle and Application Scope of Copper Plate Magnetic Induction Thickness Gauge

- 2What is a Thickness Gauge?

- 3Coating Thickness Gauge: Magnetic VS Eddy Current

- 4Performance Test and Characterization of Polyacrylate Mixed Suspension

杨庆臣 - 《北京化工大学》

- 5QNIX Nix 4200 Magnetic Induction Coating Thickness Gauge Real Photo Appreciation

- 6How to control the temperature of Spreader solution?

- 7What is the main role of talc in coating powder?

- 8Magnetic method for thickness of dry film

- 9Film Film thickness determination