Application and test method of UV aging Test Chamber in Aluminum profile

The main purpose of ultraviolet aging test for aluminum profiles is to evaluate their weather resistance and durability to determine their service life and performance in outdoor environment. Aluminum profiles are affected by factors such as ultraviolet radiation, temperature changes, humidity, atmospheric chemicals and so on in outdoor use, and ultraviolet aging test can simulate these factors to evaluate the performance stability of aluminum profiles under actual use conditions.

Here are some specific reasons:

Weather resistance assessment: Aluminum profiles are often used in application fields such as buildings, doors and windows, curtain walls and outdoor structures. In an outdoor environment, aluminum profiles will be exposed to sunlight, rain and other atmospheric factors, and long-term exposure may lead to color changes, surface oxidation, reduced gloss, etc. Through ultraviolet aging tests, ultraviolet radiation and other environmental factors can be simulated to evaluate the weather resistance of aluminum profiles to ensure that they can maintain their appearance and performance for a long time.

Durability evaluation: Aluminum profiles need to be able to withstand long-term use and the influence of the external environment, including temperature changes, humidity, wind and rain, etc. Through the ultraviolet aging test, the influence of these factors on aluminum profiles can be simulated, its durability and deformation resistance can be evaluated, and problems such as bending, deformation or cracking will not occur in long-term use.

Material selection and quality control: Through the ultraviolet aging test, the weather resistance of different material combinations or coatings under ultraviolet radiation can be evaluated, which is helpful to select suitable materials and coatings and improve the service life and performance stability of aluminum profiles. In addition, the ultraviolet aging test can also be used as part of quality control to ensure that the produced aluminum profiles meet the relevant standards and quality requirements.

Industry standard

The UV aging test of aluminum profiles usually refers to the following industry standards:

ASTM G154: Standard test method issued by the American Association for Materials and Testing (ASTM) for evaluating the ultraviolet radiation aging performance of non-metallic materials. This standard includes ultraviolet aging test methods for different materials, and is suitable for non-metallic materials such as aluminum profiles.

ISO 4892-2: The international standards organization (ISO) issued a standard to evaluate the ultraviolet radiation aging performance of plastic materials in the laboratory. Although the standard is mainly aimed at plastic materials, some of the methods and parameters can also be applied to non-plastic materials such as aluminum profiles.

AAMA 2603 / 2604 / 2605: Standards issued by the American Association of Building Manufacturers (AAMA) cover the appearance and performance requirements of coated aluminum profiles. These standards include requirements for evaluating the weather resistance and durability of aluminum profiles under ultraviolet radiation.

GB / T 1865: The standard issued by the National Standardization Administration of CHINA on the ultraviolet radiation aging test of metal surface coatings, which includes the performance evaluation requirements and test methods for metal coatings such as aluminum profiles under ultraviolet radiation.

Specific application

The following are some specific application cases of aluminum profile UV aging test:

Construction industry: aluminum profiles are widely used in doors and windows, curtain walls, sun rooms and other structures in the construction industry. Through the ultraviolet aging test, the weather resistance and performance stability of aluminum profiles in the outdoor environment can be evaluated to ensure that they can withstand ultraviolet radiation, temperature changes and atmospheric factors for a long time without color changes, surface oxidation and strength loss.

Automotive industry: Aluminum profiles are used more and more widely in the automotive industry, including body structures, roof racks, door trims, etc. Through UV aging tests, the durability and appearance stability of aluminum profiles under long-term outdoor exposure can be evaluated to ensure that they can withstand environmental factors such as UV radiation, temperature changes and humidity without deformation, cracking and surface fading.

Electronics industry: Aluminum profiles are also widely used in components such as radiators, casings and frames of electronic products. Through the UV aging test, the weather resistance and performance stability of aluminum profiles under sunlight and other environmental factors can be evaluated to ensure that they can be used for a long time without problems such as oxidation, corrosion and deformation.

Outdoor furniture: Aluminum profiles are often used in the frame and support structure of outdoor furniture. Through the ultraviolet aging test, the weather resistance and durability of aluminum profiles in outdoor environments can be evaluated to ensure that they can withstand the influence of sunlight, rain and other atmospheric factors for a long time without fading, deformation and damage.

These application cases demonstrate the important role of UV aging testing in evaluating the weather resistance and performance stability of aluminum profiles.

How to operate

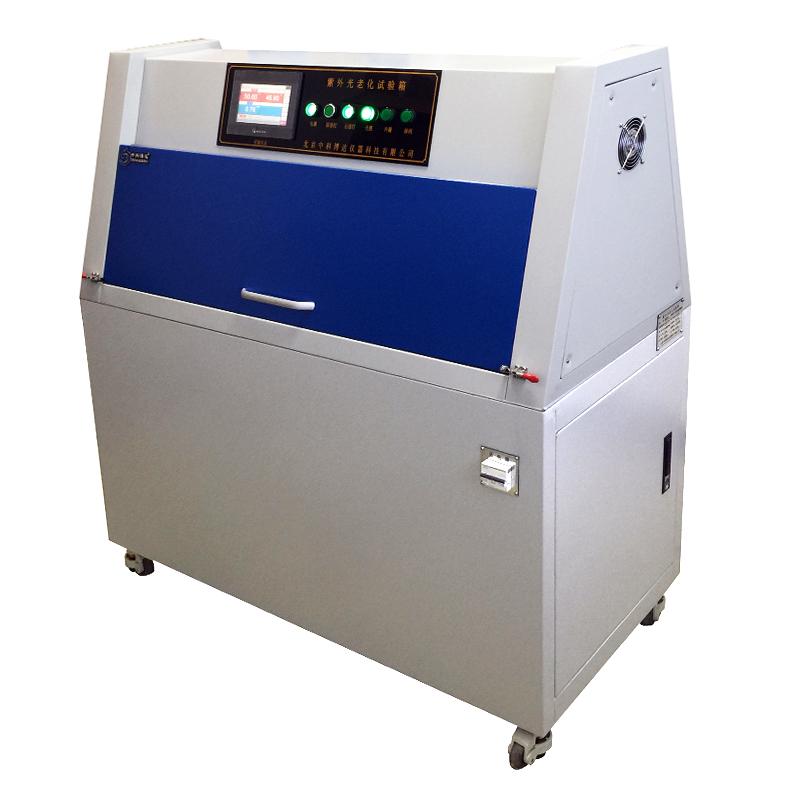

The following are the steps and precautions for testing the aging resistance of aluminum profiles using a UV aging Test Chamber in general:

Sample preparation:Select samples of aluminum profiles of the appropriate size and shape for testing. Make sure the samples are prepared in accordance with relevant standards or specifications.

Test condition setting: According to the required test conditions and standard requirements, set the parameters of the UV aging Test Chamber, including radiation intensity, temperature, humidity, etc. Ensure that the Test Chamber setting meets the relevant specifications and requirements.

Sample placement: Place the aluminum profile sample on the sample holder in the Test Chamber to ensure that the sample is flat, free of deformation and interference, and that the exposed area on the sample surface is uniform.

Test run: Start the UV aging Test Chamber to expose the sample to UV radiation and other environmental factors under the set conditions. According to the standard requirements, set the appropriate test time, usually hundreds to thousands of hours.

Regular Observation: Regularly observe changes in aluminum profile samples, including color changes, surface oxidation, gloss reduction, physical property changes, etc. Record any visible changes or damage.

Test completion and evaluation: After completing the test, remove the sample for evaluation and testing. The physical properties and surface quality of the aluminum profile sample can be tested to determine its aging resistance.

When carrying out the UV aging test, the following matters should also be noted:

Ensure that the UV aging Test Chamber equipment works normally and operates in accordance with the operation manual and safety requirements.

Check and record the temperature, humidity, radiation intensity and other parameters of the Test Chamber to ensure its stability and accuracy.

Ensure sample selection, preparation and placement meet standards and requirements.

Regularly inspect and maintain Test Chamber equipment to ensure its normal operation and accuracy.

Take care to observe and record any changes in the sample during the test for subsequent evaluation and analysis.

Through the UV aging test, important information about the weather resistance and durability of aluminum profiles in outdoor environments can be provided, helping to ensure that aluminum profiles can maintain their function and reliability for a long time in various climatic conditions.

- 1Application and test of UV aging Test Chamber in silicon oxidation

- 2Application of UV aging Test Chamber in sunscreen clothing

- 3Application and related standards of ultraviolet aging test box in ceramics

- 4Application of xenon lamp photoaging Test Chamber in industrial protective coatings

- 5Ultraviolet aging Test Chamber, aging test principle, application, operation and selection problems

- 6Ultraviolet aging Test Chamber selection skills

- 7Five test methods for evaluating coating durability

- 8Test method for yellowing resistance of polyurethane synthetic leather

王学川;周志军;张哲;强涛涛 - 《皮革与化工》

- 9Detailed Explanation of Laboratory Conditioning Test Technology for Polymer Materials

颜景莲 - 《电子世界》