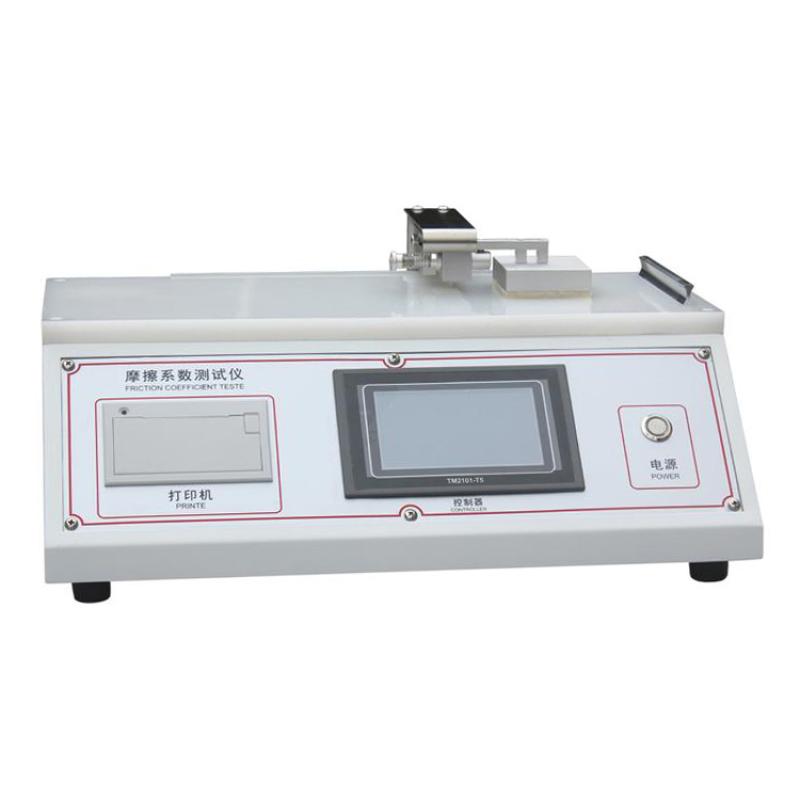

Application of Friction Tester in Rubber

橡胶是一种广泛应用于机械、汽车、电子等领域的重要材料,其摩擦性能对其使用效果和品质有着直接的影响。摩擦系数测试仪可以帮助制造商和用户评估橡胶的摩擦性能,从而确定其适用范围和使用寿命,提高产品的质量和可靠性。

在橡胶的应用中,摩擦系数测试仪主要用于测试橡胶与其他材料之间的摩擦系数,包括静摩擦系数、动摩擦系数等指标。通过测试不同工艺和原材料的摩擦系数,制造商可以确定更好的生产工艺和原材料,从而生产出更优质的橡胶制品。此外,摩擦系数测试仪还可以帮助制造商和用户了解橡胶在不同温度和湿度条件下的摩擦性能,从而确定其适用范围和使用寿命。

在测试过程中,需要先准备测试样品,并将其放置在测试台上,调整测试参数后开始测试。测试时,摩擦系数测试仪会对样品进行摩擦试验,以确定其摩擦系数。测试完成后,可以According to测试结果对橡胶的摩擦性能进行评估,从而提高产品的质量和可靠性。

Below is a table of steps to test rubber with a coefficient of friction Tester:

| Step | Describe |

|---|---|

| 1 | Prepare test samples, usually rubber sheets or rubber products |

| 2 | Place the test sample on the test bench and clamp it with the test fixture to ensure that the sample is fixed |

| 3 | According to the test requirements, adjust the test parameters of the friction coefficient Tester, such as test speed, test method, etc |

| 4 | Start the test instrument to test. The test instrument will perform a friction test on the sample |

| 5 | After the test is completed, the friction properties of the rubber are evaluated according to the test results |

NBChao reminds you: When conducting the friction coefficient test, the selection of test parameters should be adjusted according to different test requirements, such as test speed, test method, etc. In addition, the size and shape of the test sample also need to meet the test requirements to ensure the accuracy and reliability of the test results. During the test process, it is also necessary to pay attention to the handling of the test sample to avoid scratches on the surface of the sample or other defects that affect the test results.

In short, the friction coefficient Tester has important application value in the application of rubber, which can help manufacturers and users evaluate its friction performance and improve the quality and reliability of products. When conducting tests, it is necessary to pay attention to the use of the instrument and the adjustment of test parameters to ensure the accuracy and reliability of the test results.

- 1Application of Friction Coefficient Meter in Spinning & weaving products

- 2Friction Coefficient Meter How to test the aluminum foil resistance coefficient of friction?

- 3Application of Friction Tester in Coatings

- 4Benefits of using friction coefficient Testers in the plastics industry

- 5What is the coefficient of friction and how is it determined?

- 6Application and Maintenance of Friction Coefficient Tester

- 7Friction Coefficient Meter ASR-3009 operating instructions

- 8Use and maintenance of friction coefficient meter

- 9Why is coefficient of friction testing important?