Pencil Hardness Tester measurement Eletroplating tin plate surface scratch resistance

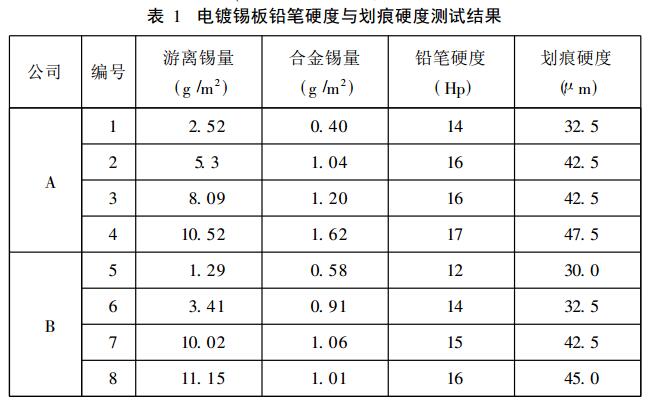

As everyone is familiar with, the main testing principle of the pencil Hardness Tester is to measure the hardness of the organic coating layer based on the pencil hardness method. In the article "Study on the Scratch Resistance of Electroplated Tin Plate Surface", scholar Liu Xiaobing cleverly used pencil Hardness Tester and other testing instruments to measure the scratch resistance of the surface of electroplated tin layer. Undoubtedly, using a pencil Hardness Tester to measure scratch resistance is undoubtedly not the original intention of designing a pencil Hardness Tester, so some special situations need to be taken into account. For example, in electroplated tin plate, it is required that the coating should not only be controlled below the dry grinding thickness of 1.5um, but also that the prepared coating should be softer. Therefore, the author has specially made some regulations in order to allow quantitative or semi-quantitative evaluation of the test results.

The test method used in this test is carried out in accordance with the international GB6739-86. It should be pointed out that according to the experience of NBCHAO Mall, the GB6739 coating film hardness pencil test method has been updated to the 2006 version. The difference between the updated versions can be found in the NBCHAO Standard Library, which will not be described here.

The operation process is as follows:

1. Make 5 scratches on the surface of the electroplated tin plate, start the test with the hardest pencil, and replace the pencils with lower grades one after another until you find a pencil with only one plowing film among the 5 scratches. The lower and lower pencils indicate the pencil hardness level of the surface of the electroplated tinplate being tested. If the surface coating of the tinplate is not plowed, use the pencil of this hardness level to represent the pencil hardness of the surface of the tinplate to be measured.

2. Because the 6B pencil in GB6739-86 is the softest grade, and in the actual test process, when the thickness of the tin plating layer is relatively large, there are often more than one plow scratches. In this case, the next one should be replaced according to the above standards. grade pencil. However, at present, there is no pencil softer than 6B, so the author has more actual test conditions, and re-graded according to the original grading standard to make the relative hardness comparison more convenient.

a) The specified hardness is divided into 20 grades, from 1Hp to 20Hp in turn. Among them, 1Hp is the hardest, 20Hp is the softest, and the hardness decreases from 1Hp→20Hp.

b) When tested with a 6H pencil, if the coating is not plowed, the hardness is defined as 1Hp; when tested with a 5H pencil, if the film is not plowed, the hardness is defined as 2Hp; and so on.

c) When testing with a 6B pencil, if among the five scratches, there is a plow mark in only one pencil mark line, it is defined as 14Hp; if there are two or more scratches with a plow mark, each pencil mark One plow scar in the mark line was defined as 15Hp, the one with two plow marks in each pencil scratch line was defined as 16Hp, and so on. This is based on the number of plow scars.

Finally, the author concluded that under certain conditions, the pencil Hardness Tester and the scratch Hardness Tester can be used to compare the strength of the scratch resistance of the electroplated tin plate, and this method is simple and effective, and is more suitable for the production site. monitor.

- 1Film hardness testing method: pendulum hardness, pencil hardness, etc

- 2ISO 15184 Pencil method to measure the hardness of paint film

- 3Analysis of hardness measurement by ASTM D3363 pencil method

- 4Pencil Hardness Tester test procedure, application and different Hardness Pencil introduction

- 5Pencil hardness testing of film

- 6Ceramic Coated Pencil Hardness Test

- 7Relevant standards for pencil Hardness Testers

- 8What is a pencil hardness test?

- 9What performance subjects are tested for water-based floor coating materials and how do they meet the standards?