NBchao Film Applicator for Thermal Paper Preparative Adhesive

Thermal paper is a special thermal material that can chemically react when heated to produce visible images or text. Thermal paper usually consists of two main parts: the substrate and the thermal layer.

1. Substrate: The substrate of thermal paper is the material used to support and transfer the thermal layer. Common substrates include paper, plastic film, etc. The choice of substrate depends on the application requirements of thermal paper, such as wear resistance, water resistance and other characteristics.

2. Thermal layer: The thermal layer is a key part of thermal paper, and it contains heat-sensitive chemicals. The thermal layer is usually composed of thermal inks or thermal dyes. When thermal paper is stimulated by thermal energy, the chemicals in the thermal layer will undergo color changes or chemical reactions to form images or text.

3. Adhesive layer: Thermal paper is generally attached to a certain test object, so a layer of adhesive needs to be prepared on the back. The adhesive is generally specially prepared hot melt adhesive.

How to prepare adhesive backing for thermal paper?

The preparation of adhesive backing for thermal paper requires certain professional equipment and materials. The following are the basic steps for general adhesive preparation:

1.Material preparation: Prepare the required raw materials, including rubber powders, solvents, stabilizers, etc. Select the right material for thermal paper applications and ensure its quality and purity.

2.Dissolve rubber powder: Add the rubber powder to an appropriate amount of solvent, such as water or organic solvent, according to the formula and ratio provided by the manufacturer. Choose the appropriate solvent according to the characteristics and solubility of the rubber powder.

3.Mixing and stirring: Mix the dissolved glue powder and solvent together, and stir with appropriate stirring equipment to ensure that the glue powder is completely dissolved and a uniform glue solution is formed.

4.Adding stabilizers: As needed, stabilizers can be added to the glue to improve the stability and viscosity of the glue and ensure its performance during preparation and use.

5.Filtration and defoaming: The glue is filtered through filtration equipment to remove suspended particles and impurities. At the same time, corresponding measures, such as vacuum defoaming, can be taken to eliminate air bubbles in the glue.

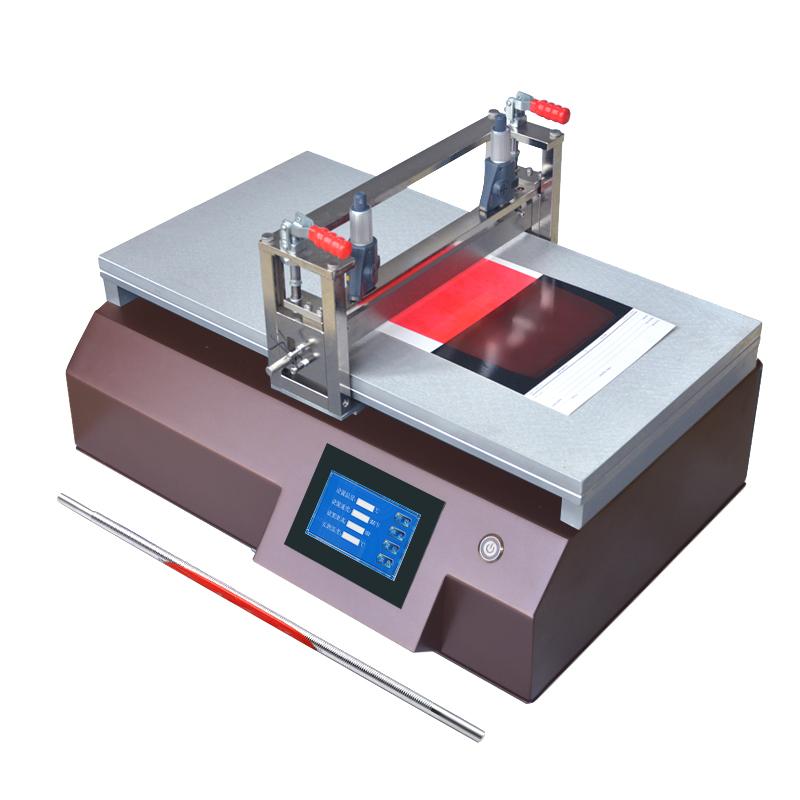

6.Adhesive Coating: Apply the glue evenly on the back of the thermal paper. Use the experimental automatic Film Applicator/roll-to-roll Film Applicator (small production) and process control to ensure that the glue is evenly and continuously applied on the surface of the paper. [Consult NBCHAO Technology for the choice of Film Applicator]

Drying and curing: Send the coated thermal paper to an oven or other drying equipment or use a heated Film Applicator for scraping. It can be dried at the same time after scraping to remove the solvent in the glue and solidify the glue to form a backing layer. Appropriate drying time and temperature control are carried out according to the properties and preparation requirements of the glue.

Cutting and Packaging: Cutting and packaging dry-cured thermal paper to obtain the final adhesive-backed thermal paper product. Ensure that the packaging process meets hygienic requirements and product quality protection.

It should be noted that the above steps are only the basic process of general preparation of adhesive backing, and the specific preparation methods and conditions may vary depending on the type of rubber powder, glue formula and equipment requirements. In actual operation, relevant manufacturer guidelines and process specifications should be followed according to specific rubber powder and preparation requirements.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 9Application of Film Applicator in PEM Research and Preparation