Coating Metering rodsFAQ

Coating Metering rod is a kind of equipment that can be used to accurately control the amount (wet film thickness) in experiment or production. It ensures the smoothness of the film layer and estimates the film thickness by controlling the coating thickness and scraping uniformity.

Here are some examples of coating Metering rods (coating rods) FAQs:

What are the selection criteria for coating Metering rods?

Different types of coatings Metering rods are suitable for which coatings?

How to choose the right coating Metering rod size and thickness?

How does the material of the coating Metering rod affect the coating results?

How to correctly use coating Metering rod for coating construction?

What are the cleaning and maintenance methods for coating Metering rods?

How long does the coating Metering rod last?

How to tell if the coating Metering rod needs to be replaced or repaired?

What are the storage and storage requirements for Coated Metering rods?

What are the common problems and Troubleshooting methods in the use of coating Metering rods?

How is the effect of coating Metering rod on coating thickness and uniformity assessed?

How are the measurement results of Coating Metering rods compared and verified with specifications or standards?

What are the scope and limitations of coating Metering rods?

How to calibrate coating Metering rods to ensure accurate coating thickness?

What are the optimization and improvement methods for coating Metering rods?

These questions cover FAQs on coating Metering rod selection, use, maintenance, Troubleshooting, and association with coating results and specifications. Specific circumstances may vary depending on the type of coating Metering rod and the application field.

What are the selection criteria for coating Metering rods?

The choice of coating Metering rod should be determined according to the viscosity of the coating material, Spreader thickness requirements and the required Spreader method. Key factors include Metering rod size, thickness, groove shape and material. Coating flowability, viscosity range, construction conditions and other factors should be considered when selecting.

Different types of coatings Metering rods are suitable for which coatings?

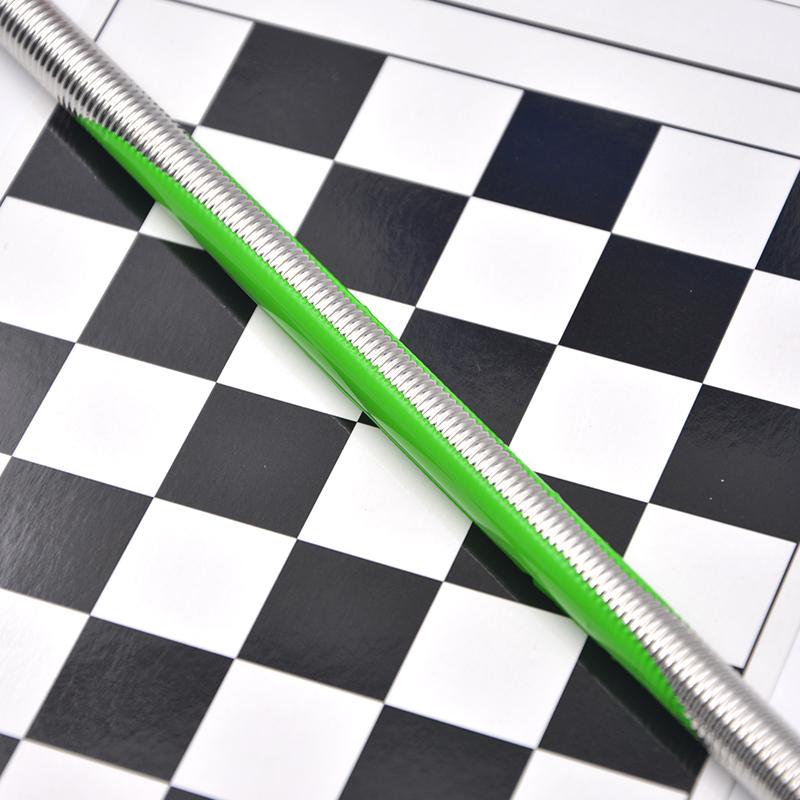

There are various types of coating Metering rods, suitable for various coating materials such as paints, Coatings, Adhesive, inks, etc. Different types of Metering rods include rectangular rods, round rods and toothed rods with different groove sizes and shapes to suit the construction requirements of different coating materials.

How to choose the right coating Metering rod size and thickness?

The size and thickness of the coating Metering rod should be selected based on the thickness requirements of the Spreader, the viscosity of the coating material, and the construction method. Common Metering rod sizes include a thickness range of 1-1000 μm, and the appropriate size can be selected according to the desired Spreader thickness. Generally speaking, larger Metering rods are suitable for thicker coatings, and smaller Metering rods are suitable for thinner coatings.

How does the material of the coating Metering rod affect the coating results?

The material of coating Metering rod should be compatible with the coating material to avoid interaction or contamination between materials. Common coating Metering rod materials include stainless steel, plastic and ceramics. The choice of material may have an impact on the gloss, Smoothness and adhesion of the coating.

How to correctly use coating Metering rod for coating construction?

When using a coated Metering rod, the Metering rod should be immersed in a Coating bucket and then evenly Spreader on the substrate to work along a specific direction. By controlling the construction speed and pressure, the desired Spreader thickness can be achieved. It is important to maintain conformity and accuracy of construction and avoid excessive or insufficient Spreader.

What are the cleaning and maintenance methods for coating Metering rods?

Cleaning and maintenance of the coated Metering rod is essential to ensure its accuracy and Reliability. Immediately after use, the Metering rod should be washed in a suitable solvent to remove residual Coating. A brush or soft cloth can be used to wipe the surface of the Metering rod. Be careful not to use hard objects or scrapers to avoid damaging the Metering rod. Regularly check the grooves and edges of the Metering rod for abrasion or deformation, and replace the damaged Metering rod in time.

How long does the coating Metering rod last?

The service life of a coated Metering rod depends on Frequency of use, construction conditions and the material mass of the Metering rod. Under normal circumstances, Metering rods can last longer if used and maintained correctly. However, if the Metering rod is damaged, abrasion or deformed, it should be replaced promptly to ensure accurate Spreader results.

How to tell if the coating Metering rod needs to be replaced or repaired?

Coating Metering rods may be subjected to abrasion, damage or deformation during use, which may affect the accuracy of the Spreader. By regularly checking the appearance, groove and edge condition of the Metering rod, it is possible to determine whether the Metering rod needs to be replaced or repaired. If the Metering rod has obvious abrasion, damage or deformation, which affects the uniformity and accuracy of the Spreader, it should be replaced or repaired in time.

What are the storage and storage requirements for Coated Metering rods?

Coating Metering rods should be stored in a dry, clean environment away from direct sunlight and chemicals. Metering rods should be stored vertically or flat to avoid stress or distortion. Care should be taken to prevent damage or contamination of Metering rods during storage and storage.

What are the common problems and Troubleshooting methods in the use of coating Metering rods?

Common coating Metering rod problems include uneven Spreader, coating thickness deviation, etc. If you encounter problems, you can check that factors such as Spreader speed, pressure, coating material viscosity are adjusted correctly. In addition, the grooves and edges of the Metering rod should also be checked for damage or abrasion. If necessary, the Metering rod can be re-calibrated or replaced.

How is the effect of coating Metering rod on coating thickness and uniformity assessed?

The use of coating Metering rods has a significant impact on coating thickness and uniformity. To evaluate coating thickness and uniformity, measurement and observation can be carried out using equipment such as Microscope, Optical inspection measuring instrument or coating thickness Measurement Instrument. By selecting appropriate measurement points, measurement areas and standard references, the thickness and uniformity of coatings can be evaluated for compliance.

How are the measurement results of Coating Metering rods compared and verified with specifications or standards?

The measurement results of the coating Metering rod can be compared and verified with the coating specification or standard. By measuring parameters such as coating thickness, uniformity and Spreader mass, the measurement results are compared with the specification or standard requirements. If there are discrepancies, the coating Metering rod can be calibrated or adjusted to ensure the accuracy and conformity of the measurement results.

What are the scope and limitations of coating Metering rods?

Coating Metering rods are suitable for a variety of coating materials and application fields, but there are some limitations. For example, for high viscosity coating materials, it may be necessary to choose a larger size Metering rod to ensure the uniformity of the Spreader. In addition, coating Metering rods may not be suitable on substrates of certain special shapes and surfaces, and Miscellaneous Spreader methods or tools may be required.

How to calibrate coating Metering rods to ensure accurate coating thickness?

The calibrating of the coating Metering rod can be achieved by comparing it with a standard coating of known thickness. Standard coatings can be obtained by the Miscellaneous Accurate Measuring method, or standard coating plates from reliable suppliers. By comparing the measurement results and making adjustments, the accuracy and conformity of the coating Metering rod can be ensured.

What are the optimization and improvement methods for coating Metering rods?

Optimization and improvement methods for coating Metering rods include changing groove shape, material selection and improving construction techniques. By optimizing the design and use of Metering rods, Spreader uniformity can be improved, Spreader thickness deviation can be reduced, and coating mass and performance can be improved. Based on actual needs and experience, experiments and research can be carried out to find suitable Metering rod configurations and use methods suitable for specific coating materials and construction requirements.

- 1Nondestructive measurement of dry coating thickness

- 2Coated steel coatings - Determination of dry-film thickness

- 3Application scheme of coating thickness test on wood board [with test video]

- 4Curved plastic coating thickness test application scheme [with test video]

- 5PosiTector200C ultrasonic coating Thickness Gauge on concrete coating thickness measurement application

- 6Measuring method of nondestructive heat spray-on lining thickness

- 7Coulomb Thickness Gauge FAQ and Its Solutions

- 8What are the FAQs for paints Thickness Gauges? How to solve it?

- 9Coating Metering rod: Mayer-Rod