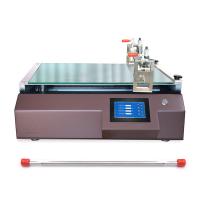

Lab Film Applicator Application of Fluorescence Agent on Ceramic Silicon Wafers [Video Demonstration]

Another new application challenge for NBCHAO laboratory coating machine: scrape coating of high-leveling fluorescent agent on small-area ceramic silicon wafers.

![Application of laboratory film coating machine to apply fluorescent agent on ceramic silicon wafer [Video demonstration] with picture 1](http://img.nbchao.com/upload/editor/image/20230718/1689676018358057378.jpg)

Firstly, let me introduce the application significance of applying fluorescent agent on ceramic silicon wafer. The application of laboratory coating machine to apply fluorescent agent on ceramic silicon wafer is mainly to form a uniform and precise fluorescent layer on the surface of ceramic silicon wafer to enhance its fluorescent effect and function. This application is of great importance in many fields of scientific research and industry. Here are a few common applications:

1. Preparation of fluorescent layer: The laboratory coating machine can evenly coat the fluorescent agent on the surface of ceramic silicon wafers. This ensures that the fluorescer is evenly distributed across the surface, improving fluorescence and visibility.

2. Fabrication of fluorescent sensors: After coating fluorescent agents on ceramic silicon wafers, they can be made into fluorescent layers for sensor applications. These fluorescent sensors can be used to detect and measure various parameters in the environment, such as temperature, pressure, humidity, etc. The choice of fluorescer can be optimized according to the desired sensor response.

3. Biomedical application: The laboratory coating machine can be used to prepare fluorescent layers on ceramic silicon wafers for fluorescent marking in biomedical research and applications. By coating specific fluorescent agents on ceramic silicon wafers, applications such as biomolecular detection, microscope imaging, and cell tracking can be realized.

4. Improvement of optical devices: coating fluorescent agents on ceramic silicon wafers can improve the performance and characteristics of optical devices. For example, in optoelectronic devices, by coating a fluorescent layer on ceramic silicon wafers, it can enhance light absorption and increase luminous efficiency, or be used to make optical devices such as lasers and light-emitting diodes.

Of course, in addition to the above points, there are other specific application meanings and purposes.

In this application, there are actually several operational difficulties. First, the substrate of the ceramic silicon wafer is a circular piece with a small area. This small-area scraping coating is very easy to overturn, such as substrate movement, coating not completely scraped, etc.; second, the sample is a fluorescent agent with high leveling properties. For samples with high leveling properties, the speed of manual feeding should be consistent with the scraping speed of the coating machine to avoid excessive flow of the sample and affect the coating effect.

![Application of fluorescent agent on ceramic silicon wafer by laboratory coating machine [Video demonstration] with picture 2](http://img.nbchao.com/upload/editor/image/20230718/1689676009920086922.jpg)

Let's take a look at how the north and south tide technology is successfully scraped and painted, pay attention to the details and skills of the operation.

Take a look at the final coating effect, as shown below:

For more applications of film coating machines, you can communicate with Beichao Technology~

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research