Importance and role of coating bar in Coating and coating applications

Introduction

The concept and use of coating bar are introduced.

This article discusses the importance of coating bars in coating and coating applications.

Basic principle and classification of coating bars

Explain the fundamentals of the coating bar Spreader method and how to achieve coating uniformity and thickness control with coating bars.

The classification introduces different types of coating bars, such as wire-wound, formed, quantitative coating bar, etc.

Application of coating bar in Coatings and coatings industry

Explore the wide application of coating bars in the Coatings and Coatings industry.

For different types of coatings, this paper introduces how the coating bar plays a role in the process of color scheme, coloring, sizing, etc.

Application of coating bars in the laboratory

Emphasizes the critical role of coating bars in the laboratory for the preparation of standardized coating samples.

This paper describes how to control the wet film thickness by coating bar, which provides a basis for material performance evaluation and research.

Development and evolution of coating bars

Review the historical evolution of coating bars, from the original winding rods to the development of modern quantitative coating bars.

The continuous innovation and progress of coating bar in materials science and engineering are introduced.

Advantages and challenges of coating bars

Analyze the advantages of coating bars as a Spreader tool, such as accurate control, repeatability, etc.

Explore possible challenges such as Coating adaptability, cleaning and maintenance.

Conclusion

Summarize the importance and diversification of coating bars in Coating and coating applications.

Emphasize the value of coating bars in laboratory research, quality control and innovation.

Introduction

As a Spreader tool, coating bar plays an indispensable role in the field of Coatings and coatings. With its precise control and uniform Spreader effect, it provides an effective means for Coating prepative and coating applications. This article will explore the importance of coating bar in the Coatings and Coatings industry, as well as its diverse role in laboratory research, quality control and innovation.

Basic principle and classification of coating bars

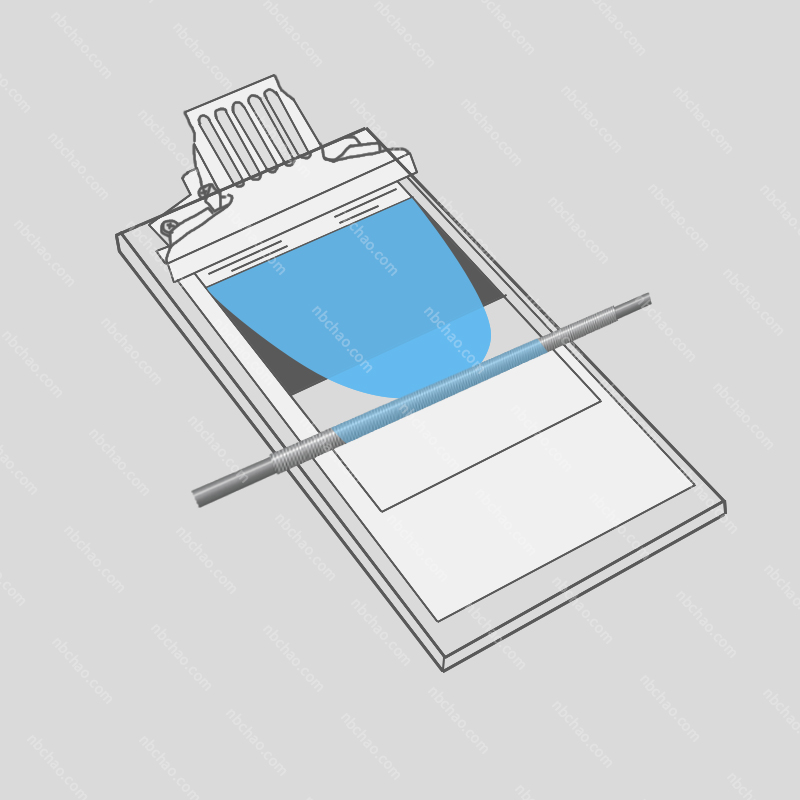

The coating bar Spreader method is a commonly used Spreader technique. Its basic principle is to evenly Spreader the exact Coating film layer on the substrate by scraping off excess liquid. There are various classifications of coating bars, including wire-wound, formed, quantitative coating bar and other different types. Wire-wound coating bar controls the thickness of the Spreader by winding steel wires of different diameters on the steel rod. The formed coating bar, on the other hand, extrudes grooves on the smooth steel rod through a cold extrusion process to achieve the control of the Spreader wet-film.

Application of coating bar in Coatings and coatings industry

Coating bar has a wide range of applications in the Coating and Coatings industry. In processes such as color scheme, coloring and sizing, coating bar can achieve uniform Spreader of Coatings and ensure the conformity of coatings. In dyestuff scraping, coating bar helps to apply dyestuff evenly to the substrate for accurate color reduction. In addition, coating bar also plays an important role in varnishes, Wallpaper inks and other fields, providing support for accurate Spreader of Coatings.

Application of coating bars in the laboratory

In laboratory research, the coating bar also plays a key role. As a Mayer Rods type, the coating bar is used to prepare standardized coating samples, thus providing a reliable means for the evaluation and study of material performance. By controlling the wet film thickness, researchers can gain insight into the performance characteristics of Coatings, providing an important basis for the development and optimization of New materials. The application of coating bars in the laboratory not only speeds up the research process, but also ensures the repeatability of results.

Development and evolution of coating bars

The development and evolution of coating bar has undergone a century of evolution. From the original wire-wound coating bar to the extrusion-molded coating bar developed today, coating bar has continued to innovate and adapt to the needs of different industries. With the continuous advancement of material science and engineering technology, coating bar has made significant progress in accurately controlling the amount of Spreader and wet film thickness control. The development and evolution of coating bar has not only brought efficiency improvements to the Coating industry, but also provided more powerful tools for laboratory research.

Advantages and challenges of coating bars

As a Spreader tool, the coating bar has the advantages of precise control of the amount of Spreader and high repeatability. It can ensure the conformity and uniformity of the coating, providing a reliable means for Coating prepative. However, the adaptability of different types of Coatings and the cleaning and maintenance of the coating bar are still challenges that need to be solved. For some special Coatings, the selection and operation of the coating bar require more careful consideration to ensure the Spreader effect.

Conclusion

As a Spreader tool, coating bar plays an irreplaceable role in Coating and coating applications. Coating bar is one of the key tools, whether it is Coating prepative in industrial production or material performance evaluation in laboratory research. Its precise Spreader control and repeatability provide strong support for Coating process optimization and material innovation. With the continuous advancement of science and technology, the importance of coating bar in the field of Coatings and coatings will continue to increase, bringing new possibilities and opportunities to the development of the industry.

- 1Application of coating bar in automatic film machine

- 2How to clean the wire rod applicator? Tips for proper cleaning of the film rod

- 3Experimental Automatic Film Applicator Application Case High-precision preparatory finish coating on iron plate

- 4Metering Coating Stick Notes

- 5Preparation of Composite Membrane Extracts with Stainless Steel Scraper

周伟 - 《北京化工大学》

- 6Spreader method of dipping: Spreader (Wire Spreader)

- 7Introduction to the Spreader method

- 8Printing ink scraper new experimental renderings show NBchao production

南北潮 - 《南北潮商城》

- 9A large collection of wire rod Spreader technology (selection technology, use and operation, free trial)