Coating fineness measurement and its role in Coating quality control

The fineness of coatings is an important parameter to measure the dispersion of pigments and extenders in coatings. Fineness directly affects the performance and mass of coatings, such as film formation mass, Gloss, durability, and the storage stability of coatings. In order to ensure the mass of coatings, the determination of fineness becomes crucial. This article will introduce the definition of fineness, test methods and its role in the Coating industry.

1. Definition, purpose and meaning

Fineness is a measure of the degree of dispersion of pigments and extenders in Coatings, usually in microns (μm). Its reading on a standard finometer indicates the depth of the groove in the Fineness Meter. The fineness of the Coating directly affects the Coating mass, such as Color uniformity, Surface Gloss, firmness of the film, etc. Coatings with finer particles generally have better wettability and dispersion, helping to prepare high-mass paint films.

2. Test method

There are several standard methods for the determination of Coating fineness, including GB/T 1724-79 Coating fineness determination method, GB/T 6753.1 Coating fineness of ground determination and ISO1524 Paints, varnishes and Printing ink fineness of ground determination.

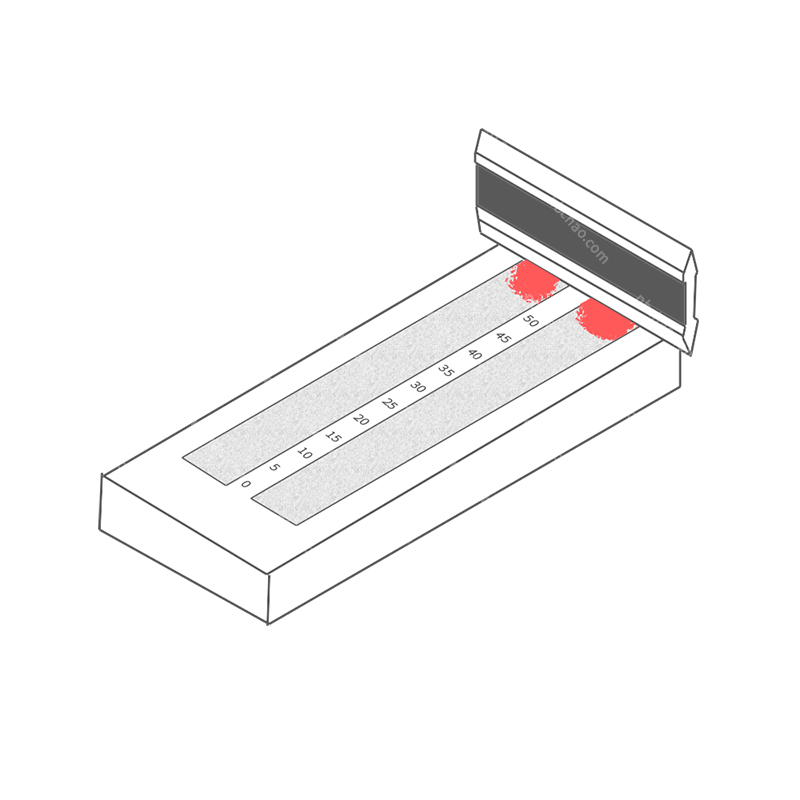

GB/T 1724 Coating Fineness Determination Method: This method judges the fineness of the Coating by scraping the sample vertically on the Fineness of Grinding Gauge, and judging the fineness of the Coating according to the minimum scraper depth where the particles are uniformly exposed.

GB/T 6753.1 Determination of Coating fineness of ground: This method requires scraping the sample with Grindometer at a specified angle and time, and then judging the fineness according to the location of the particle density points.

3. Operational points of inspection methods

When performing fineness measurement, you need to pay attention to the following operation points:

Select the Appropriate Fineness Measurement Range.

Stir the sample well to ensure sample representativeness.

Scraper operation within the specified time and angle.

The fineness is judged according to the position where the particles are uniformly exposed.

Attention should be paid to the influence of factors such as the volatilization rate of the solvent, the representativeness of the sample and the abrasion of the drawdown blade on the measurement results.

4. Role and influencing factors

The determination of fineness is crucial to the intrinsic quality control of Coatings. Coating particles with lower fineness are finer, have better dispersibility, and the resulting paint film is more uniform and smooth, and is less prone to precipitation and clump during storage. Therefore, fineness determination can help Coating manufacturers adjust Coating formulations for better Coating performance and mass.

The influencing factors of fineness measurement include the representativeness of the sample, the viscosity of the Coating, the volatilization rate of the solvent, the reading time, and air bubbles. Therefore, when measuring fineness, it is necessary to pay attention to the above factors to ensure the accuracy of the measurement results.

Summarize

Fineness is a key indicator of Coating mass, which affects the performance and mass of Coatings. Through appropriate fineness measurement methods, the dispersion of pigments and extenders in Coatings can be evaluated, thereby providing effective guidance for Coating manufacturing and quality control. Fineness measurement helps to ensure the stability and conformity of Coating mass and improve Coating performance and application effect.

- 1Coating fineness test method and influencing factors

- 2Detection Steps of Coating Fineness and Operation Method of Ground Gauge

- 3Enamel paste fineness requirements

- 4Performance subjects that must be inspected in the production process of water-based wood coatings? What are the indicators?

- 5These properties of water-based alkyd resin coatings need to be tested? Tell you how to reach the standard?

- 6What performance subjects should standard coil coatings test? What are the technical indicators?

- 7What properties should solvent-based polyurethane coatings be tested for, and how can they be considered up to standard?

- 8What subjects are generally tested for architectural paint color paste?

- 9How to measure the fineness of ink? What are the precautions