How to effectively monitor and extend the service life of coating rods

The Spreader process plays a vital role when applying coatings to substrates such as paper, film, and foil. However, one of the biggest challenges in Spreader operation is how to monitor and measure the service life of coating rods. This article will combine expertise to introduce effective methods to monitor the life of coating rods and explore how to extend their service life.

1. Monitor the service life of the coating rod

Knowing how to tell when to replace a coating rod is critical to avoid mass problems. Often, a coating rod needs to be discontinued when it can no longer be applied with enough coating or when the coating is no longer smooth and uniform. However, these judgments vary by application and can be monitored in a number of ways, such as:

Direct coating weight measurement;

Production tracking;

Light luminance;

Opacity;

Visual coating mass inspection;

Functional performance testing (such as Cobb testing, MVTR cup testing, etc.).

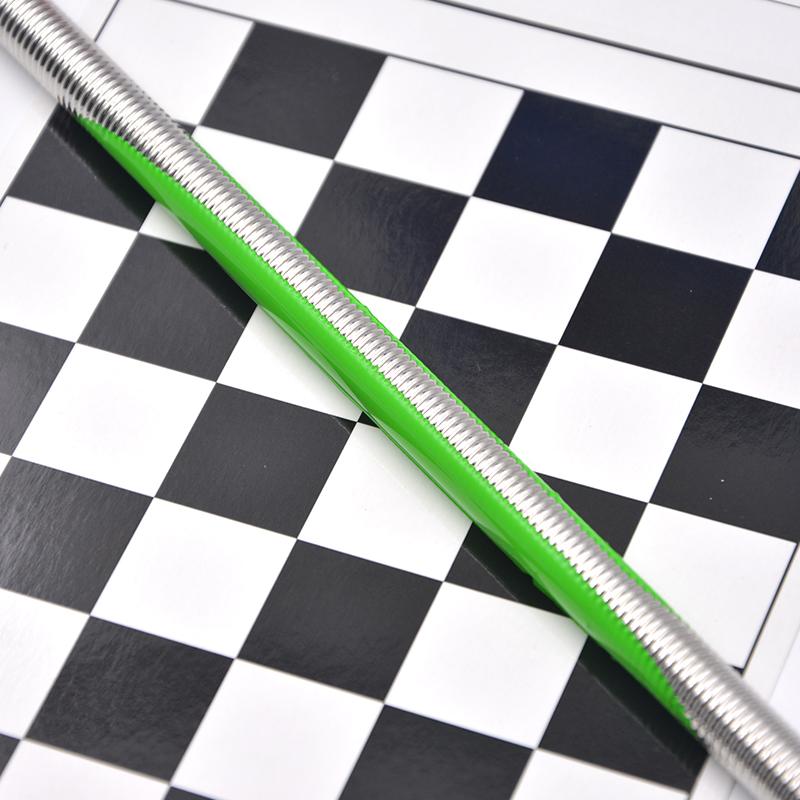

2. Distinction between physical abrasion and pollution

The end of life of a coating rod is usually attributed to two main factors: physical abrasion and contamination. In order to determine when a coating rod needs to be replaced, it is necessary to accurately distinguish between these two factors. Physical abrasion refers to the abrasion of the linear profile of the coating rod due to factors such as friction, abrasion, heat, etc. during normal operation. Contamination refers to the contamination of the coated linear profile by dry coating and Miscellaneous residues, thereby reducing the open area of the linear profile. In order to determine whether it is pure abrasion or contamination, an abrasion analysis can be performed to better determine the problem in the operation.

3. How to measure and maximize service life

Measurement of coating rod life is a critical step in ensuring Spreader mass. This can be achieved by:

- Individual rod production tracking: For each coating rod, keep a production history to accurately track its life. For example, by tracking the life of each rod, a replacement decision can be made when it is half its life.

- Online Spreader weight measurement system: Using the online Spreader weight measurement system, Spreader mass can be monitored in real time and defects can be found in time, thereby improving Spreader mass.

4. Extend the service life of the coating rod

In order to maximize the service life of the coating rod, there are the following suggestions:

Storage and handling: Coating rods are precision instruments and must be stored and handled with care. When not in use, the protective cover should be kept on the coating rod to prevent damage. In addition, care should be taken to avoid bending when storing the coating rod.

Cleaning: The coating rod should be cleaned in time after the end of the production cycle to avoid the accumulation of residues. According to the nature of the Coating, use a suitable method for cleaning.

Handling: When moving the coating rod, avoid hitting objects that may damage its surface to prevent Spreader defects.

Swirl/spin: The coating rod should be swirl/spin continuously to ensure that abrasion occurs uniformly over the entire linear profile.

Summarize

Coating rods are a key component to ensure Spreader mass. Through effective monitoring and correct maintenance methods, the service life of coating rods can be extended, Spreader mass can be improved, and the mass and stability of the final product can be guaranteed.

-

CHINA BLD-01C paper Thickness Gauge$ 425.00

- 1Why Do Film Applicators Need to Change Their Wires Regularly?

- 2Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets

- 3The overlooked role of Mayer Rods in laboratory wet-film preparation

- 4Advantages and Categories of Mayer Rods in Spreader wet-film prepative

- 5Mayer Rods: The right-hand man for hiding power tests

- 6Different types of coating rods

- 7Application of coating rods on Direct Thermal Label Stock

- 8Types of Mayer Rods and their differences

- 9What are the main differences between Mayer Rods and doctor blade Applicators?