Influence of smoothness on paper printing and its solution

In the printing industry, the smoothness of paper is a key indicator that has a direct impact on print quality and results. Smoothness measures the convex and concave properties of the surface of paper or cardboard, which are essential to ensure uniform transfer of printing inks and the quality of the final print.

Factors Affecting Paper Smoothness

The smoothness of paper is affected by a number of factors, including fiber morphology, pulp beating, weaving method of paper mesh and blanket, wet pressing pressure, and the presence or absence of calendering, filling, and coating. Poor smoothness of paper may lead to the appearance of false dot printing and virtual printing during the printing process, thereby reducing the visual quality of the printed matter.

Measurement method of smoothness

Smoothness is measured by a specific measurement method. In the paper preparation process, a common measurement method is to measure the time it takes for air to pass through the gap between the paper surface and the glass surface under a certain vacuum. If this time is long, it means that the smoothness of the paper is better.

The effect of smoothness on printing

Smoothness directly affects the printing effect of paper. Most of the physical, chemical and mechanical properties of paper are determined at the time of papermaking, so it is difficult for printers to change the smoothness of paper. For paper with poor smoothness, problems such as false imprints, flaws, and reduced layers may occur during printing.

Ways to address the impact of smoothness

When using paper with poor smoothness, printers can take some measures to compensate for its effects. For example, the printing pressure can be appropriately increased, the fluidity of the ink can be enhanced, and the ink with better wettability can be selected to reduce the problem of blotting emptiness caused by uneven paper. Although it is not easy to change the smoothness of the paper, taking corresponding measures in terms of process operation and ink selection can reduce its impact to a certain extent.

In conclusion, the smoothness of paper is an important factor in printing quality, which directly affects the printing effect and final quality during the printing process. Understanding the influencing factors of paper smoothness and taking corresponding solutions will help the printing industry better meet this challenge and improve the quality and value of printed matter.

-

CHINA BLD-01C paper Thickness Gauge$ 425.00

-

-

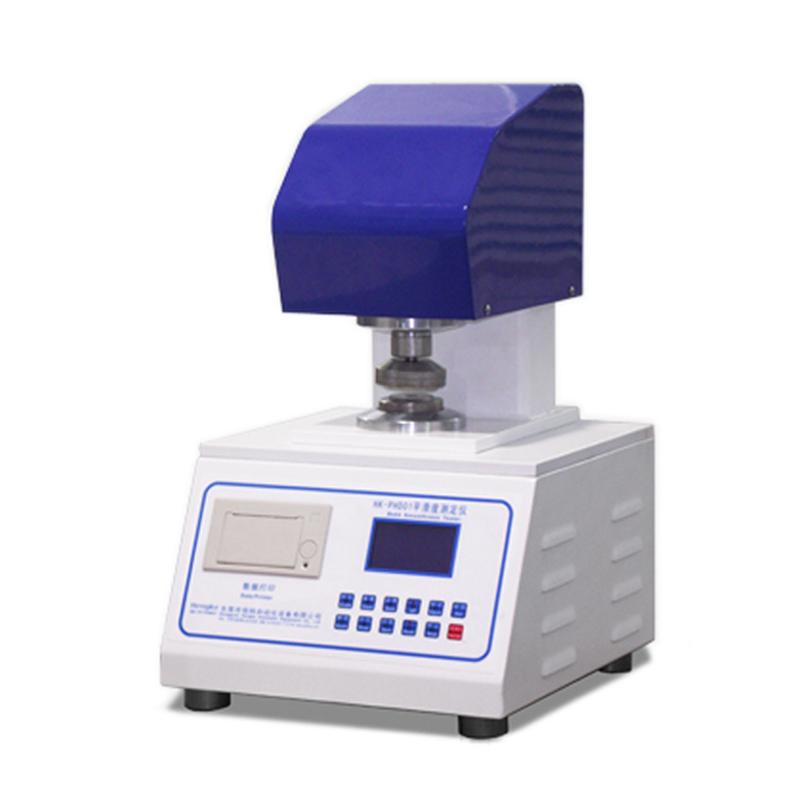

CHINA BLD-PH10 Smoothness Meter$ 1695.00

-

-

-

-

-